Wire and Cable Elongation Tester (RT-1308)

Additional information

Copper Wire Metal Wire Elongation Test Machine

This instrument is suitable for testing the elongation characteristics and tensile strength of metal wires, such as copper wire, aluminum wire, aluminum-magnesium alloy wire, and iron wire. The circuit adopts operational integrated circuits and process control, without the need for manual calculation, and automatically displays the percentage of elongation. The elongation length adopts laser sensing technology, with high sensing accuracy.

Product Details:

Products Description

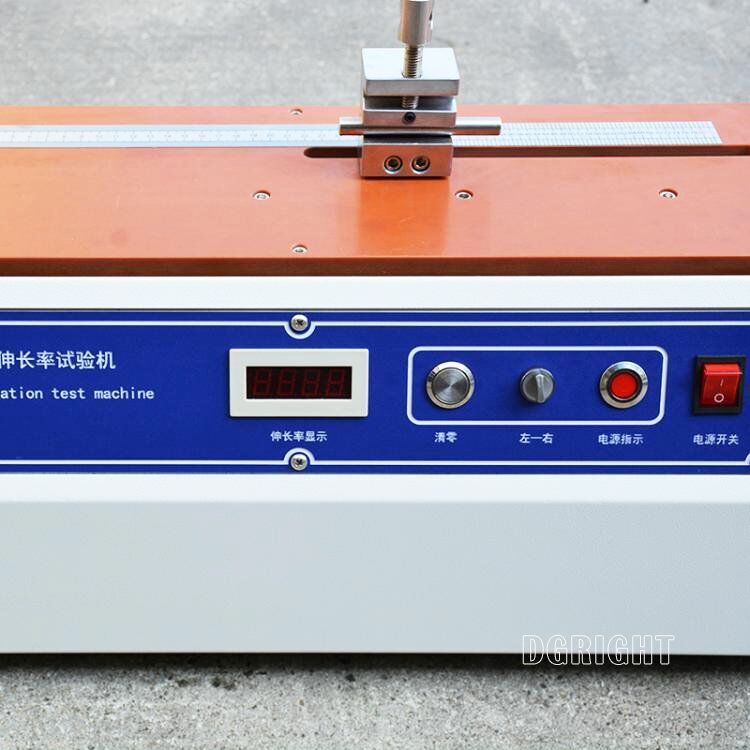

RT-1308 Wire and Cable Elongation Tester is suitable for aluminum, copper, iron and other metal materials to measure elongation. The tester is testing elongation of metal materials; Using an advanced software program and sophisticated electronic sensing technology to measure the elongation of tensile specimens, automatically converted into % and displayed on the LED display. According to the conductive wire, coupled with advanced control technology, enable this device to automatically calculate the high-precision percentage, with fully automatic features, simple operation, easy to read, and accurate value.

Specification

| Product name | Wire and cable elongation tester |

| Model | RT-1308A |

| Diameter range | 0.03 ~ 1.0mm |

| Tensile speed | 250 ~ 300mm/min |

| Tension stroke | 250mm |

| Extended range | 0 ~ 48% |

| Display accuracy | 0.1% |

| Input power | AC220V 50/60Hz |

| Size | 50 × 21 × 24 (cm) |

| Weight | 13kg |

| Product name | Wire and cable elongation tester with Tensile Sensor |

| Model | RT-1308B |

| Diameter range | 0.03-1.0mm(0.05-2.0mm/1.0-3.2mm is optional) |

| Tensile speed | 250 ~ 300mm/min |

| Tension stroke | 250mm |

| Extended range | 0 ~ 60% |

| Elongation resolution | 0.1% |

| Range of force | 0.001Kg ~ 50Kg |

| Input power | AC220V 50/60Hz |

| Size | 50 × 22 × 24 (cm) |

| Weight | 19kg |

Note:

Standards Compliant

This machine complies with UL, CSA, GB, ASTM, VDE, IEC and other testing standards.

Product Feature

1. The box is treated with electrostatic baking paint. The whole machine is designed reasonably, and the structure is secure, stable and accurate.

2. The circuit adopts advanced software programming and precise electronic sensing technology to measure the tensile of the specimen.

3. Adopt the mechanical transmission system composed of high efficiency inner circulating screw and constant speed motor, and the machine runs smoothly.

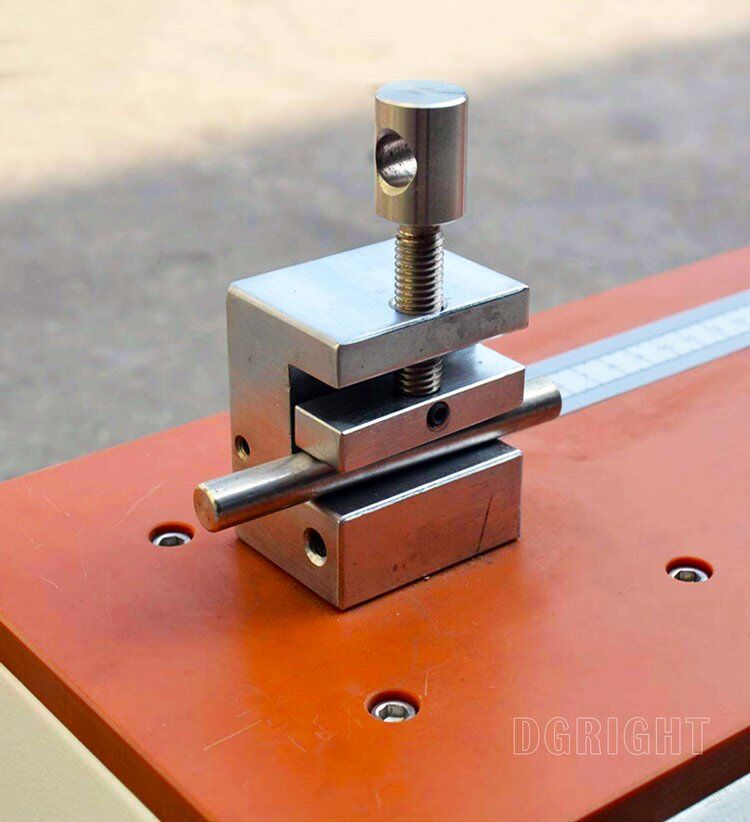

4. The fixture adopts advanced anti-skid handling technology to avoid fracture of the specimen in the fixture and improve the test.

5. The clamping device is fitted with a fixed screw, and the test piece can be fixed on the fixture while the test piece can be fixed on both ends of the test piece.

6. LED digital percentage indicator and pointer indicating elongation scale display elongation percentage, no need for human.

7. The electric wood insulation board is the working face, which makes the test more convenient and accurate.

8. Optional digital display/pointer push pull gauge test specimen pulling force value, multi-function test.

Packing:

Calculation Formula for Elongation of Wire

The formula for calculating elongation is f =(L2-L1) ÷ L1 x 100%. Elongation refers to the percentage ratio of the elongation of the original gauge length to the original gauge length of a specimen after tensile fracture. Elongation is an important parameter that represents the uniform or stable deformation of a material.

Operating Instructions and Precautions for Wire Elongation Tester

1. Fix the product to be tested onto the left and right fixtures of the wire elongation tester.

1.1 Firstly, the mobile fixture on the right end of the device should be at the standard distance position, with a distance of 250mm between the two fixtures.

1.2. Fix the left and right ends of the product with left and right fixtures respectively, and the product should be kept straight.

1.3. Wrap the screws on the sides of the left and right fixtures at both ends of the product a few times to prevent it from falling into the machine when removed.

2. Before testing, the reset button should be pressed to make the elongation meter display 0.

3. After completing all the above steps of debugging preparation, if there are no abnormalities, turn on the power switch and then turn the left and right switches to the right to start testing. If there are any abnormalities during testing, press the power switch to stop.

4. Record the test results in detail.

5. Test completed: ① Fix all screws of the testing instrument and check if the fixture is loose; ② Organize the test bench.

6. Attention:

6.1 Before the experiment, the first thing to check is whether the equipment has fixed the test product properly.

6.2 After all debugging preparations are ready, the equipment should be checked for smooth operation during testing.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

IEC60587 High Voltage Tracking Index Tester 45Hz to 60Hz (RT-727)

-

Cable Life Tester Automatic Plug Wire Swing Bending Testing Machine (RT-1302B)

-

Thermal Radiation Flame Propagation Tester (RT-746)

-

ASTM D149 High Voltage Breakdown Tester 50KV 100KV 150KV (RT-1320)

-

Horizontal Digital Power Plug USB Insertion Force Tester (RT-1311)

-

RT-1306 Thermal Stability Testing Machine

-

RT-1616 Enameled Wire Softening Breakdown Tester

-

RT-1303 Heating Deformation Testing Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)