Vertical High Speed Mixer | Hot and Cold Mixing Machine for PVC & Plastic Compounding (RT-743)

High Speed PVC Powder Heat Mixer – Industrial Mixing Unit Manufacturer

Upgrade your compounding process! Our Vertical High Speed Mixer delivers efficient hot & cold mixing, precise temperature control, and homogeneous blending for PVC, plastics, and powders.

Product Details:

1. Overview

The Vertical High Speed Mixer is a high-performance mixing system designed for heating, cooling, and uniform blending of PVC, plastic granules, and chemical powders.

It integrates hot and cold mixing stages in one unit, ensuring rapid and efficient processing while maintaining consistent quality.

Widely used in plastic compounding, masterbatch production, polymer modification, chemical, and food industries, it improves productivity and product stability.

2. Working Principle

The mixer operates through a two-stage hot and cold mixing process:

-

Hot Mixing Stage: High-speed blades generate frictional heat to soften and disperse additives uniformly. Temperature control prevents thermal degradation.

-

Cold Mixing Stage: The material is cooled using circulating water, stabilizing it and preventing moisture absorption or agglomeration.

-

Discharge: The cooled, homogenized mixture is ready for extrusion, granulation, or molding.

3. Operating Process

-

Preparation: Ensure the machine is clean, water supply connected, and electrical system ready.

-

Feeding: Load PVC resin, stabilizers, colorants, and additives into the hot mixer.

-

Hot Mixing: Set the speed and temperature. Mix until uniform.

-

Cooling: Transfer to cooling mixer; reduce temperature quickly.

-

Discharging: Release the cooled mixture for downstream processing.

-

Cleaning & Maintenance: Clean the chamber and blades after each batch.

4. Key Features

-

Integrated hot & cold mixing system for high efficiency

-

Precise temperature control and rapid mixing

-

Durable stainless steel construction

-

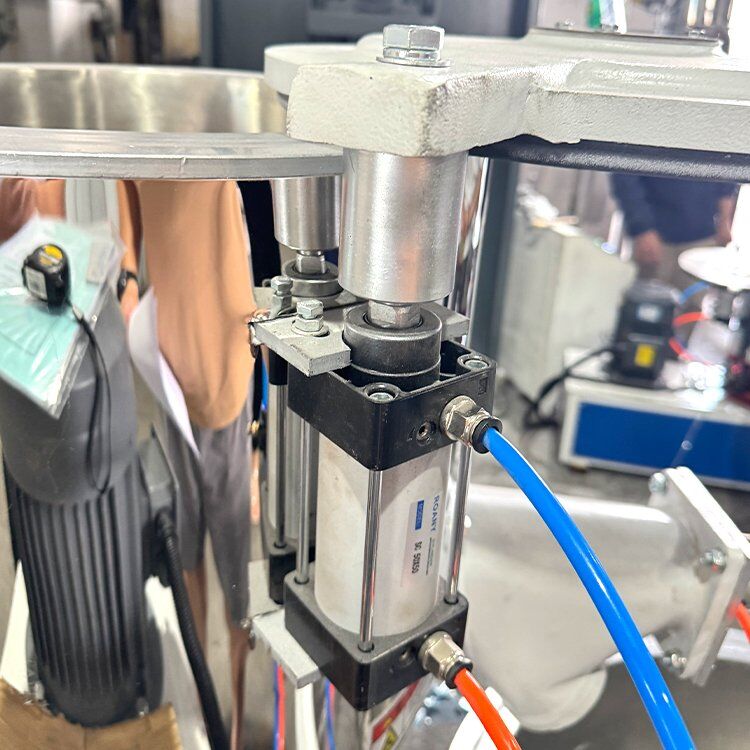

PLC control with automatic feeding, discharging, and safety interlocks

-

Optional customization for capacity, material, and configuration

5. Technical Specifications

| Model | CAP | Effective Capacity | Speed | Power | Heat method | Discharge method | Production |

| RT-743-5A | 5L | 3L | 1450rpm | 1.1kw | self-friction | Manual | 8kg/h |

| RT-743-10A | 10L | 7L | 1450rpm | 3kw | 16kg/h | ||

| RT-743-50A | 50L | 35L | 750/1500rpm | 7/11kw | electrical | Pneumatic | 82kg/h |

| RT-743-100A | 100L | 75L | 650/1300rpm | 14/22kw | 165kg/h | ||

| RT-743-200A | 200L | 150L | 475/950rpm | 30/42kw | 330kg/h | ||

| RT-743-300A | 300L | 225L | 475/950rpm | 40/55kw | 495kg/h | ||

| RT-743-500A | 500L | 375L | 430/860rpm | 55/175kw | 825kg/h | ||

| RT-743-800A | 800L | 600L | 370/740rpm | 83/110kw | 1320kg/h | ||

| RT-743-200C | 200L | 150L | 475/950rpm | 30/42kw | self-friction | 330kg/h | |

| RT-743-300C | 300L | 225L | 475/950rpm | 40/55kw | 495kg/h | ||

| RT-743-500C | 500L | 375L | 430/860rpm | 55/75kw | 825kg/h |

(Custom sizes available upon request)

6. Safety Features

-

Automatic lid interlock

-

Emergency stop button

-

Overload protection for motors and drives

-

Temperature limit control

-

Safety shields and guards

-

PLC alarm system for motor faults, temperature deviation, or blockage

7. Maintenance Guidelines

Daily: Clean mixing chamber and blades, check moving parts

Weekly: Inspect blade wear, temperature sensors, and water system

Monthly: Lubricate bearings, check electrical connections and emergency systems

Long-term: Replace worn seals, gaskets, and blades; inspect motor and drive system; maintain a maintenance log

8. Applications

-

PVC dry blending (pipes, fittings, cables)

-

Masterbatch and color concentrate preparation

-

PE/PP additives compounding

-

Chemical powders, resins, and thermoplastics

-

Food-grade powder homogenization

9. Advantages

-

High-speed heating and rapid cooling improve production efficiency

-

Ensures uniform dispersion of additives

-

Reduces mixing time and energy consumption

-

Provides consistent quality and stable downstream processing

-

Fully automatic and safe operation

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-723A TH-9001 Carbon Black Content Tester

-

RT-718 TGA/DTA/DSC Synchronous Plastic Thermogravimetric Analysis Differential Thermal Analyzer

-

RT-712B Automatic Limited Oxygen Index Tester

-

RT-710 UL94 Flammability Combustion Test Chamber For Plastic(Vertical and Horizontal flame)

-

RT-706 2000mm Height Falling Ball Impact Testing Machine

-

RT-129 Small PP PVC Injection Molding Machine

-

RT-111 Voltage Breakdown Tester

-

RT-129 Desktop Manual Plastic Injection Molding Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)