RT-110 Two Roll Open Mixing Mill (Electronic Heating & Water Cooling)

Additional information

| Model | RT-110 |

|---|---|

| Roller Diameter | 4 inch, 6 inch, 8 inch, 10 inch |

| Roller temperature | RT~300℃ |

| Heating method | Electronic Heating+Water-cooled cooling |

RT-110 Two Roll Open Mixing Mill (Electronic Heating & Water Cooling)

This machine suitable for plastic industry polymer material mixing and processing such as, PVC, color master batch. Making the raw material and compound mixing, and achieve the required color and quality. The machine adopts special heated mold, roll surface temperature uniformity, never take off a layer, sample thickness can be mixed, the machine safety protection device, convenience to use.

Reference standard:

GB 6038-2006 Rubber ingredients of rubber testing, mixing and Vulcanization equipment and operating procedures.

GBT 13577-1992 Mill for rubber and plastics

HGT 2149-2004 Open rubber mixing machine, plastic mixing mill test methods

JBT 53113-1999 Open plastic mixing mill product quality grading

Product Details:

Equipment summary:

This machine suitable for plastic industry polymer material mixing and processing such as, PVC, color master batch. Making the raw material and compound mixing, and achieve the required color and quality. The machine adopts special heated mold, roll surface temperature uniformity, never take off a layer, sample thickness can be mixed, the machine safety protection device, convenience to use.

Reference standard:

GB 6038-2006 Rubber ingredients of rubber testing, mixing and Vulcanization equipment and operating procedures.

GBT 13577-1992 Mill for rubber and plastics

HGT 2149-2004 Open rubber mixing machine, plastic mixing mill test methods

JBT 53113-1999 Open plastic mixing mill product quality grading

Technique Feature:

⑴The core technology from Taiwan, The main parts adopt the French schneider.

⑵The whole floor,easy installation, driving mode is uniaxial output ensure the torsion big,Imported bearings reduce rubbing force to ensure save electricity, low noise and rubber thickness uniform parallel controllable.

⑶Roll adopts the vanadium titanium alloy chilled cast iron,roll hardness(HRC)50-60,surface is hard wear-resisting, durable. Roller lumen finish machining to ensure that the roller body cooling quickly and evenly.

⑷The machine adopts manual adjustment mode, Thickness control precision,easy operation,High safety factor .

⑸The machine is equipped with an emergency brake, When emergency accidents,four corners have emergency switch, a number of brake system, convenient quick stop machine.

⑹Transmission device adopts hardened reducer,compact structure,transmission efficiency,little noise.

⑺Automatic oiling device to ensure that long-term oil for driving part,Make up the pump forget supply damage to part of serious consequences.

(8)Two motor driven,arbitrary roller speed ratio before and after implementation,easy to operation;

(9)Integral plate,easy installation.Driving mode is uniaxial output to ensure the big torque,imported bearings to reduce friction to save electricity, reduce noise, and Rubber thickness uniform parallel controllable.

(10)Transmission device adopts double double frequency converter control,Low noise, long service life.

Technical parameters:

| Model Project | RT-110-1 | RT-110-2 | RT-110-3 | RT-110-4 |

| Roller Diameter (metric /inch) | 120mm/4in | 160mm/6in | 200mm/8in | 250mm/10in |

| Roller face width | 320mm | 320mm | 320mm | 320mm |

| Mixing capacity | 0.3~2kg | 0.5~3kg | 1~10kg | 2~15kg |

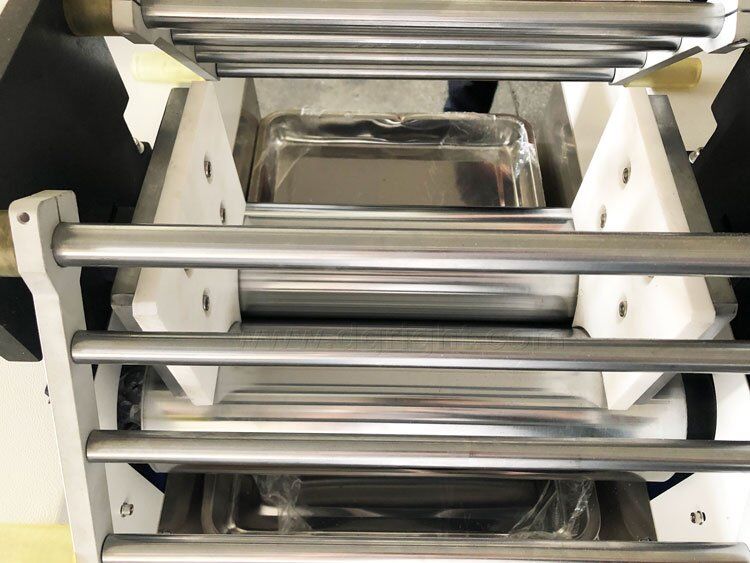

| Picking device | SUS304 Stainless steel hopper | SUS304 Stainless steel hopper | SUS304 Stainless steel hopper | SUS304 Stainless steel hopper |

| Roller temperature | RT~300℃ | RT~300℃ | RT~300℃ | RT~300℃ |

| Heating method | Water-cooled cooling | Water-cooled cooling | Water-cooled cooling | Water-cooled cooling |

| Temp Accuracy | ±3C | ±3C | ±3C | ±3C |

| temperature controller | PID control | PID control | PID control | PID control |

| Roller Rev | frequency control | frequency control | frequency control | frequency control |

| Roller ratio adjusted according requirements | 1:1.22/1:1.35 1:1.4 | 1:1.22/1:1.35 1:1.4 | 1:1.1/1:1.22 1:1.4/1:1.7 | 1:1.1/1:1.22 1:1.4/1:1.7 |

| Roller hardness | 50~60HRC | 50~60HRC | 50~60HRC | 50~60HRC |

| Roller processing | Mirror polishing chrome plated | Mirror polishing chrome plated | Mirror polishing chrome plated | Mirror polishing chrome plated |

| Roller spacing | 0.1~8mm adjustable | 0.1~8mm adjustable | 0.1~8mm adjustable | 0.1~10mm adjustable |

| Spacing display mode | Calibration/digital display | Calibration/digital display | Calibration/digital display | Calibration/digital display |

| Safety device | Collision type emergency stop | Collision type emergency stop | Collision type emergency stop | Collision type emergency stop |

| Safety device number | 7 PCS | 7 PCS | 7 PCS | 7 PCS |

| Special function | Emergency stop inversion | Emergency stop inversion | Emergency stop inversion | Emergency stop inversion |

| Motor power | 4.5KW | 5.5KW | 7.5KW | 15KW |

| Power voltage | 3phase,AC380V | 3phase,AC380V | 3phase,AC380V | 3phase,AC380V |

| Dimension | 1*1.1*1.4(M) | 1*1.1*1.5(M) | 1.5*1.2*1.5(M) | 1.5*1.3*1.6(M) |

| Weight | About 2T | About 2.5T | About 3.4T | About 4T |

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-110 Botton Type Two Roll Open Mixing Mill (Electronic Heating & Water Cooling)

-

Plastic Hot Press Forming and Rubber Vulcanizing Press Machine Manufacturers

-

RT-108B Rubber Rebound Resilience Impact Tester

-

RT-107 Digital Rubber Akron Abrasion Machine

-

RT-106 DIN Abrasion Tester

-

RT-110A Rubber Two Roll Mill Machine (electrical heating)

-

Rubber Low Temperature Brittleness Tester (RT-103)

-

RT-115 Pneumatic Rubber Tensile Test Cut Specimen Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)