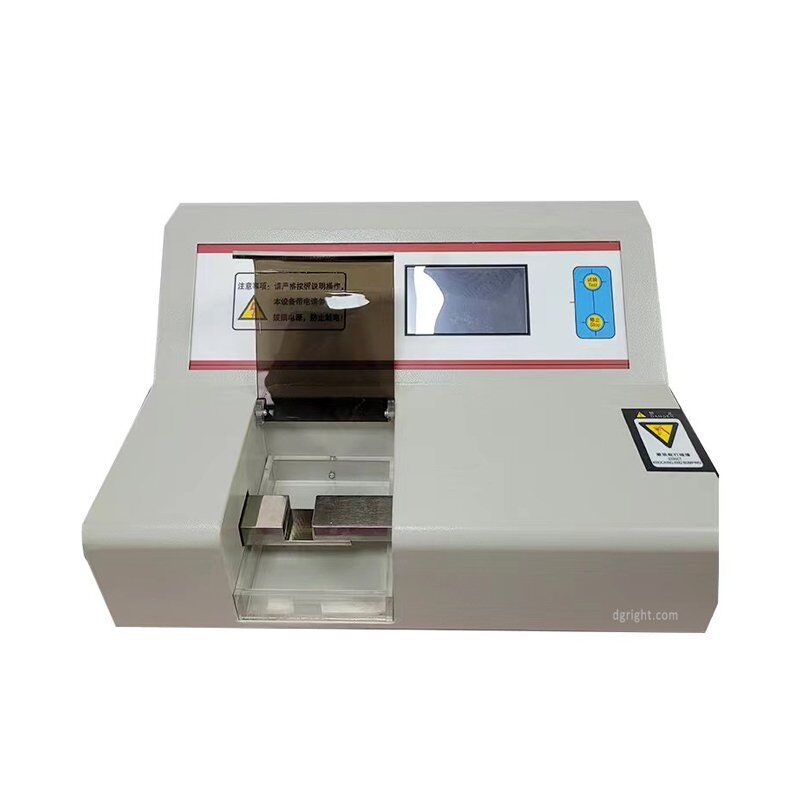

Intelligent Tablet Hardness Tester 0.2-500N (RT-1030)

Best Tablet Hardness Tester Machine

To ensure that pharmaceutical pills and tablets have the ideal casing, a tablet hardness tester is required to analyze the mechanical integrity of a tablet accurately. The RT-1030 Tablet Hardness Tester measures the weight, thickness, diameter/length, width, and hardness of virtually all tablet shapes, including round, oval, oblong, and even unique shapes.

Product Details:

The RT-1030 tablet hardness tester is an essential instrument for testing the hardness value of tablets. Its leading technical indicators have reached or exceeded the advanced level of similar instruments at home and abroad, with a hardness testing range of 0-30Kgf, a testing accuracy of up to ± 0.01kg, and a diameter testing range of 2-35mm. This instrument is controlled by a single-chip microcomputer equipped with high-precision pressure sensors and a digital display of hardness values, making it very easy to operate. Application scope: Crushing hardness tester for tablets, candy tablets, milk tablets, etc

Product Feature

1. Manual loading, automatic feed testing, and automatic statistical printing.

2. High-precision pressure sensor with digital display.

3. It can continuously measure the hardness value of tablets, with a maximum of 100 tablets tested per group.

4. Automatically detect the diameter of the film, saving testing time.

5. Automatically display peak values and automatically latch peak values.

6. It can automatically print and process data, display and record the hardness value of each tested tablet, calculate the maximum value, minimum value, average value, mean square value, and dispersion coefficient, and print the test and statistical results.

7. Automatic testing of hardness values: Display the force value curve and real-time value in a time-sharing manner.

8. Automatic network data transmission, automatic detection of network communication status, automatic diagnosis, automatic alarm, and automatic data supplementation to the database after the network is unobstructed.

Product Parameters

| Measuring range | 0.2-300N (0.2-30kg) |

| Resolution | 0.01N (0.01kg) |

| Measurement accuracy | ±0.5%FS |

| Measurement repeatability | ±1% |

| Number of test pieces per group | ≤100片 |

| Tablet testing diameter | 2-35mm |

| Test diameter accuracy | 0.01mm |

| Power supply | 40W |

| Dimensions | 420mmX305mmX215mm |

| Net Weight | 20㎏ |

Working Principle

Objective

The main purpose of tablet hardness testing is to determine the fracture point of the tablet or the force required to rupture the tablet. This measurement is crucial for evaluating the compressive strength of tablets and ensuring consistent quality and performance.

Testing Equipment

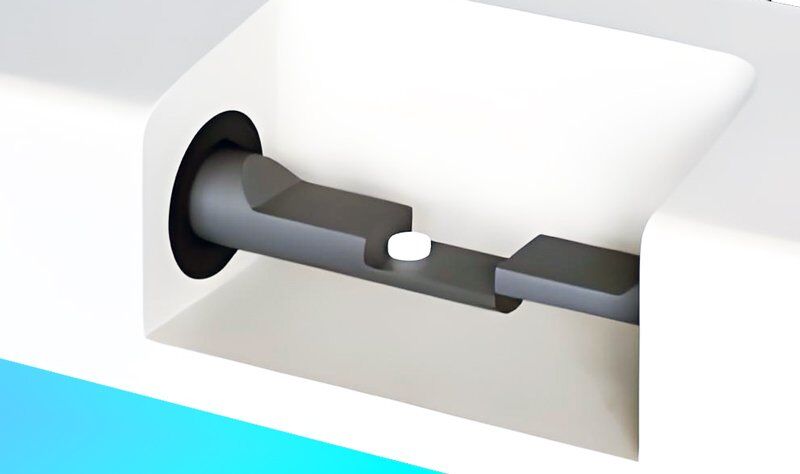

Tablet hardness testing is usually conducted using a hardness tester or tablet hardness testing instrument. The device consists of a measuring head or a probe used to apply controlled incremental force to tablets.

Application

The tablet is placed between the upper and lower anvils of the hardness tester. The upper anvil exerts a downward force on the tablet while the lower anvil provides support. The force gradually increases until the tablet ruptures or breaks.

Measure

During the testing process, continuously monitor the applied force and record the maximum force required to break the tablet. This force is typically measured in kilopounds (kp) or newtons (N). The tablet hardness value represents the ability of the tablet to withstand pressure.

Acceptance Criteria

Compare the measured tablet hardness value with the pre-set acceptance criteria or specifications. These standards are determined during the tablet formulation and development phase, and are based on the expected use and processing conditions of the tablets. If the measured hardness value is within the specified range, the tablet is considered acceptable; Otherwise, it may be considered too weak or too hard.

Batch Variation

Tablet hardness testing is crucial for detecting differences in tablet strength between different batches of the same formula. By establishing an acceptable hardness range, manufacturers can maintain consistent tablet quality and ensure that tablets have similar mechanical properties in different production runs.

Quality Assurance

Tablet hardness testing is an indispensable part of the pharmaceutical quality control process. It helps identify any issues with formulation, compression, or other manufacturing parameters that may affect tablet strength and integrity. By monitoring and controlling tablet hardness, manufacturers can minimize the risk of tablet rupture during processing and ensure reliable dose delivery to patients.

Recommend Products

Touchscreen Type Tablet Hardness Tester (RT-1030A)

Adopting high-precision pressure sensors.

LCD display screen is selected for display, with optional Chinese or English interface.

Automatically collect, analyze, print, and display measurement data.

Combination Type Tablet Hardness Tester+Tablet Friability Tester (RT-1030B)

This product combines the functions of measuring the hardness and brittleness of tablet drugs.

Reasonable structure, stable performance, easy operation, precise and reliable.

Complete Combination Type Tablet Tester (RT-1030C)

Tablet Hardness Testers

Disintegration Testers

Friability Testers

Dissolution Tester

Efficient and convenient, meeting various testing needs.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)