High Precision Servo Control Plate Vulcanizing Hot Pressing Molding Machine (RT-109G)

Additional information

High Precision Servo Rubber Flat Vulcanizing Machine

- High precision control

- Intelligent operation

- High safety performance

- Energy saving and environmental protection

- Multifunctionality

Product Details:

Our Advantages:

The advantages of the RT-109G Servo Flat Vulcanizing Machine mainly include the following aspects:

-

High precision control:

The servo flat vulcanizing machine adopts high-precision displacement sensors and mechanical limits, which can achieve high-precision pressure and displacement control. Its high repeatability accuracy enables online detection of pressure and position consistency in the process, ensuring the quality of product molding.

-

Intelligent operation:

The device adopts touch screen control and has a user-friendly interface. Users can directly input parameters such as pressure, stroke, temperature, and holding time, making operation convenient. In addition, it can store press fit data and automatically generate production reports, improving production efficiency and data management convenience.

-

High safety performance:

The servo flat vulcanizing machine is equipped with a high-sensitivity reflective grating safety protection system, three-sided guardrails, and a two-handed operation design to ensure safe operation. At the same time, the device is equipped with an emergency button, further enhancing the safety of operation.

-

Energy saving and environmental protection:

Adopting a servo hydraulic system, the motor only works when the oil cylinder is running, and the flow rate is given as needed without overflow, which can meet the requirements of different processes for speed and pressure changes, and run more smoothly, with significant energy-saving effects.

-

Multifunctionality:

The servo flat vulcanizing machine can store multiple sets of parameter programs, and users can access the corresponding programs for production according to their needs. This avoids the trouble of repeatedly adjusting parameters when changing different products and improves production efficiency.

Product Description:

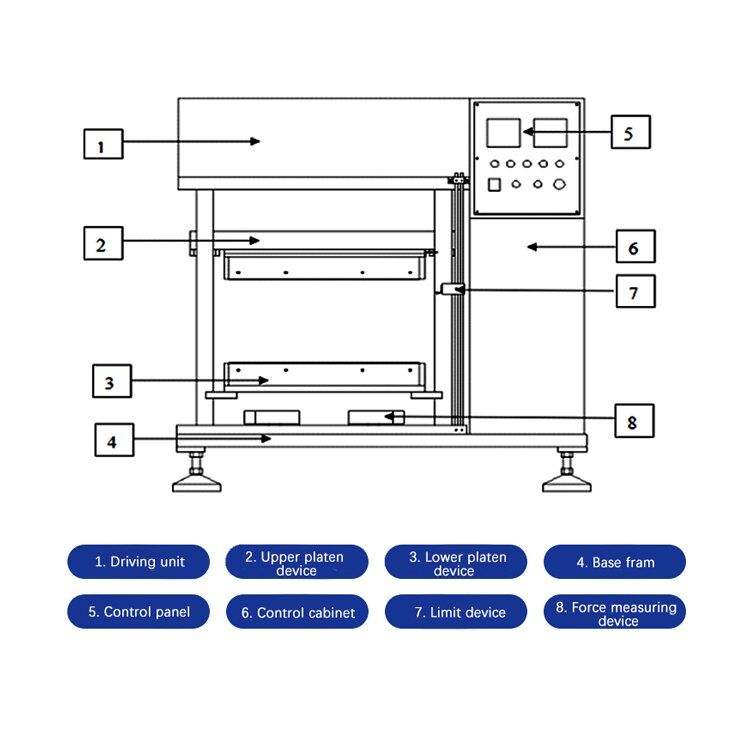

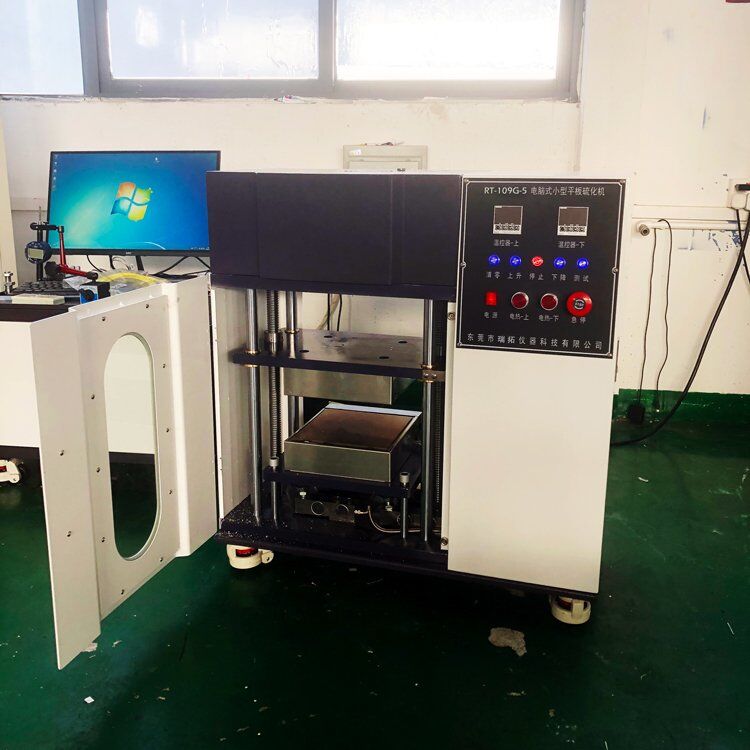

The RT-109G hot press machine is primarily used for pressing various rubber model products and non-model products. It can also be used for pressing different types of thermosetting plastics and foaming rubber and plastic products. The machine has an independent power mechanism and electrical system. It also features a centralized push-button control system, enabling the adjustment of working pressure and heating temperature within a specific range.

Specification:

| Model | RT109G-1 | RT109G-2 | RT109G-5 | RT109G-10 |

| Pressure capacity | 2kg-1T | 5kg-2T | 10kg-5T | 50kg-10T |

| Pressure Control Precision | ±2.5kg | ±5kg | ±20kg | ±50kg |

| Calculation of pressure | Pressure/sample mold plate area = pressure For example: the pressure plate is: 200*100mm, the maximum pressure is 1.5mpa, the pressure control precision is: 0.01mpa. | |||

| Plate Size | 200*200/250*250/300*300/350*350/400*400/450*450/500*500【mm】 | |||

| Material of Hot Plate | High-temperature resistant imported steel plate, surface carbonization quenching, special treatment of fast thermal conductivity, pressure parallel non-deformation, wear-resistant. | |||

| Pressure plate hardness | 50~60HRC | |||

| Pressure plate flatness | ≤0.03mm | |||

| Plate parallelism | ≤0.16mm | |||

| Temperature range | Normal temperature -250℃ [can be customized up to 500℃] | |||

| Two hot plates | The hot plate can be set to control the temperature separately | |||

| Heating method | electrical heating | |||

| Cooling method | natural air cooling | |||

| Cylinder Stroke | Max 150mm [larger stroke can be customized] | |||

| Platen travel speed | 0.1mm-500mm/min | 0.1mm-300mm/min | ||

| Pressure sensor | 1T | 2T | 5T | 10T |

| Safety device | Safety shield, safety door | |||

| Mold frame [optional] | Customizable | |||

| Machine size | (W×D×H)650×550×1300 mm | (W×D×H)800×650×1500 mm | ||

| Overall weight | ≈350kg | ≈480kg | ||

Heating Plate Features:

Adopting imported high-temperature resistant steel, the surface is treated by deep carbonization, hard chrome plating, and other processes, which has the characteristics of fast heat transfer, fast cooling, corrosion resistance, high hardness, no deformation, and so on. The back built-in heater and thermostat provide high power, fast warming, sensitive temperature measurement, uniformity, and a small temperature error range.

Guide Columns:

Four hardened and precisely positioned columns and hydraulic cylinders, supported by thick steel plate seats throughout the control box to support the hydraulic platform, on columns with self-lubricating bronze bearings, guided sliding, lifting and lowering smoothly and noiselessly; the top and back of the tablet press, surrounded by heavy-duty steel to provide additional safety protection for the operator; the upper part of the sheet metal – -with inserted thermocouples in the center near the surface.

RT-109G High Precision Servo Flat Vulcanizing Machine Operation Methods:

1、Use the level meter on the machine to make horizontal adjustments of the testing machine (adjusted when installing the machine or moving the machine).

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

ASTM D395 ISO815 Vulcanized Rubber Distortion Permanent Compression Tester RT-113A

-

RT-133 Rubber Compression Heat Generation Flexometer Testing Machine (ASTM-D623)

-

RT-109F Vacuum Vulcanizing Machine For Silicone Products Line

-

Lab Oil Heating Two Roll Mill ( 12 inch or above)

-

RT-118 Rubber Trimming Machine

-

RT-110A Rubber Two Roll Mill Machine (electrical heating)

-

RT-115 Pneumatic Rubber Tensile Test Cut Specimen Machine

-

Rubber Moving Die Rheometer MDR Rotorless Curemeter Price (RT-101)

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)