RT-133 Rubber Compression Heat Generation Flexometer Testing Machine (ASTM-D623)

30 ~ 85 IRHD Vulcanized Rubber Flexometer Compression Heat Tester

This machine is used to test the compression heat generation and fatigue of vulcanized rubber with a hardness of less than 85 IRHD. It’s utilized for flexural testing (Heat Generation test) and fatigue testing in tensile, compression and shear modes to determine the heat generation on the surface and inside of the sample.

The machine applies a certain compression load to the specimen through an inert lever system, and a periodic high-frequency compression with a specified amplitude to the specimen through a transmission system to determine the compression fatigue temperature rise and fatigue life of the specimen in a certain period of time at room temperature or higher than room temperature.

By applying a specified compression load to the specimen and compressing the specimen periodically with a certain amplitude and frequency, the compression fatigue temperature rise, static compression deformation rate, dynamic compression deformation rate, permanent deformation, and fatigue life of the specimen within a certain period of time are measured.

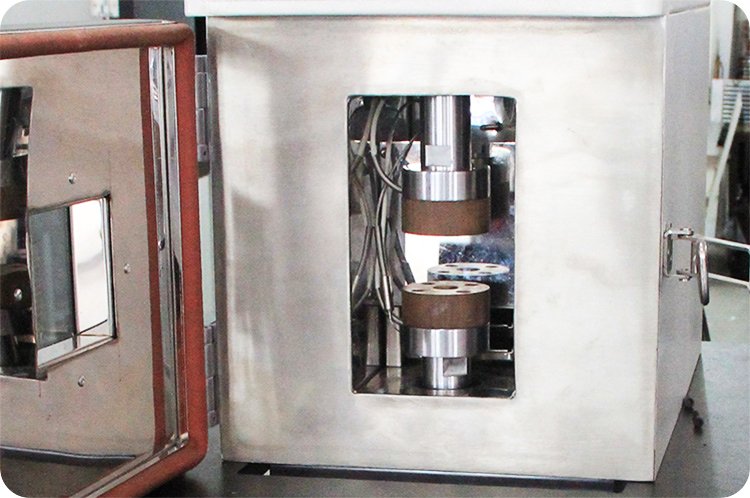

Product Details:

Parameters:

| Model | RT-133 |

| Chamber Temperature | RT+10℃~120℃ |

| Chamber Temperature accuracy | ±1.0℃ |

| Chamber size(W×D×H) | 130mm×100mm×230mm |

| Force capacity | 5KN |

| Specimen low sensing temperature range | RT~260℃ |

| Temperature deviation | ±1.0℃ |

| Sensing temperature range at the center of the specimen | RT~260℃ |

| Temperature deviation | ±1.0℃ |

| Specimen oscillation frequency range | 10.0Hz~30.0Hz (Optional Settings) |

| Frequency deviation of specimen | ≤±0.2Hz |

| Compression stroke range | 1.00mm~8.00mm (Manual Adjustment) |

| Compression Stroke Value | 4.45mm、5.71mm、6.35mm |

| Specimen Prestress | 1.00MPa±0.03MPa、2.00MPa±0.06MPa |

| Specimen pre-stress loading method | Motor-driven load cell sensing method |

| Specimen specifications | Ø17.80±0.15mm;Height:25.00±0.25mm |

| Specimen base up/down travel | 0.1mm~18.00mm |

| Specimen base up/down speed | 5mm/min |

| Controller | U70 |

| Communication Type | RJ45 |

| Software | Flexometer |

| Machine size(W×D×H) | 68cm×96cm×125cm |

| Weight(about) | Host(450kg);Control box(90kg) |

| Power | 1∮, AC 220V, 50HZ (Country-specific or designated) |

RT-133 Rubber Compression Heat Tester Product Features:

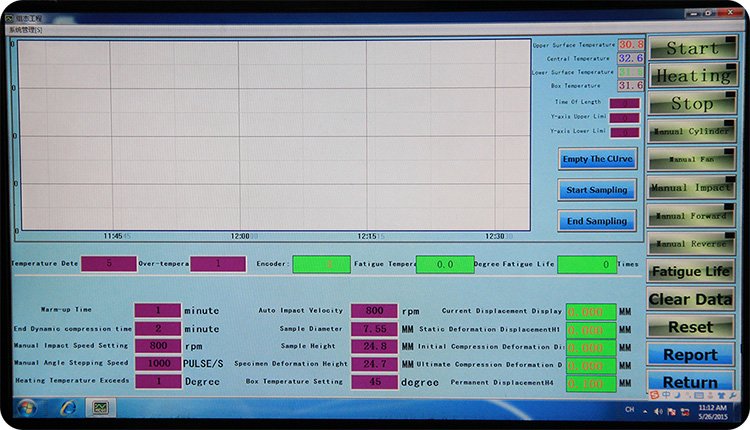

1. Adopting computer system control, simple and convenient operation;

2. Unique thermal insulation layer design of temperature box body, good heat preservation performance, fast temperature recovery;

3. Excellent design concept, easy to adjust the stroke;

4. Digital setting temperature, using intelligent PID regulation accurate temperature control;

5. Adopt a unique transmission structure design to ensure that the whole machine runs quietly, smoothly, and with slight vibration;

6. Multi-channel temperature sensors, respectively, the ambient temperature, the specimen compression after the heat caused by the temperature change;

7. An intelligent electronic control system uses servo motors and high-precision displacement sensors to adjust the level of the lever device automatically to measure the compression deformation of a powerful software system.

8. software system for Windows operating system, Windows operating interface, can switch the Chinese / English interface;

9. Software instantly displays and records the deformation, temperature, and other related parameters; can capture the deformation of each time point, temperature and other parameters; record the temperature change trend of the test process;

10. Various test types can be selected; you can arbitrarily set the report items.

Meet Standards:

ISO 4666-3-2017

Rubber, vulcanized – Determination of temperature rise and resistance to fatigue in flexometer testing – Part 3: Compression flexometer (constant-strain type);

ASTM D623-07(2019)

Standard Test Methods for Rubber Property—Heat Generation and Flexing Fatigue In Compression.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

Automatic Opening and Closing Rubber Dispersion Kneader (RT-123)

-

Turn Over Type Rubber Internal Mixer Machine (RT-120)

-

Plastic Hot Press Forming and Rubber Vulcanizing Press Machine Manufacturers

-

RT-119 ASTM G65 Dry Sand Rubber Wheel Abrasion Tester

-

RT-118 Rubber Trimming Machine

-

Demattia Flexing Fatigue Tester (RT-105)

-

RT-120B 10L Laboratory Banbury Rubber Internal Mixer

-

Professional Manufacturer Offer Lab Rubber Mooney Viscometer Price (RT-102)

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)