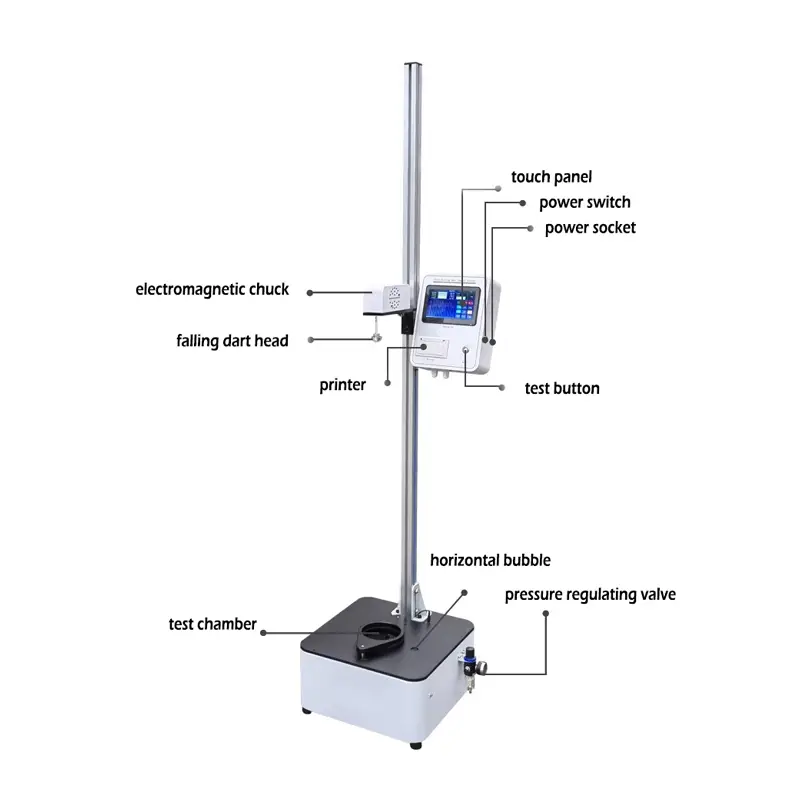

Free-Falling Dart Impact Tester for Plastic Films & Packaging Material (RT-720)

RT-720 High Precision Drop Falling Dart Impact Tester

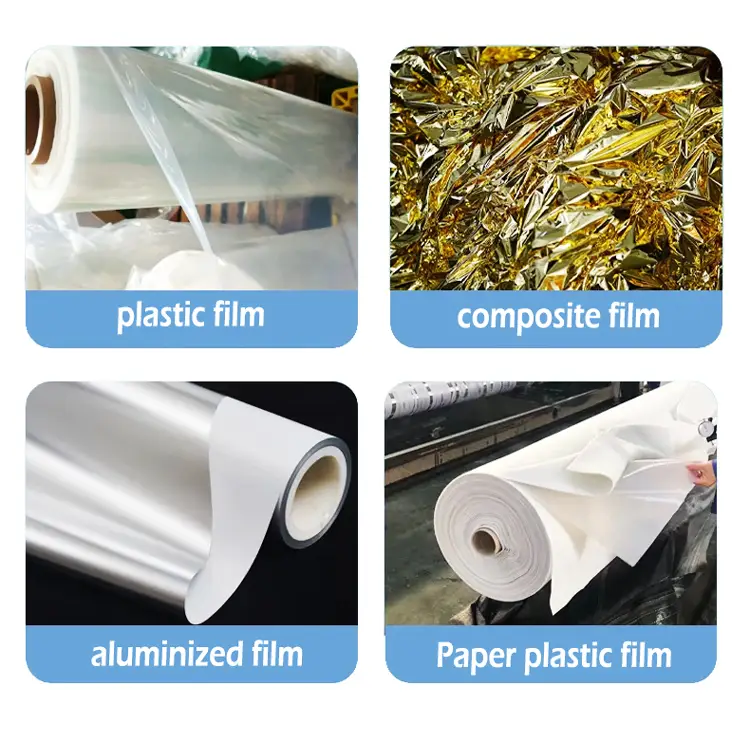

Apply to plastic film or chip which thickness less than 1mm impact by fall darts in a given great freedom to fall, test the impact quality and energy were when 50% plastic film or chip was damaged.

Product Details:

Product Overview

The Plastic Film Drop Dart Impact Tester is a high-precision testing instrument designed to determine the impact resistance and toughness of plastic films, sheets, and flexible packaging materials. By allowing a dart to freely fall from a specified height and strike the specimen, this tester accurately measures the energy or mass required to cause film failure. It is widely used in the packaging, film production, and materials research industries to ensure product quality, durability, and compliance with international standards.

Key Features & Advantages

✅ Compliant with International Standards

-

Fully conforms to ASTM D1709 (Methods A & B), ISO 7765-1, and GB/T 9639 test methods.

-

Suitable for a wide range of materials including plastic films, composite films, laminated structures, and aluminum-plastic packaging.

-

Determines the energy level (or mass) at which 50% of specimens fail under specified impact conditions.

✅ High Precision & Stability

-

Accurate free-fall mechanism ensures consistent drop height and impact point.

-

Electromagnetic release system minimizes operator error.

-

Sturdy frame and high-strength components guarantee long-term mechanical stability and repeatability.

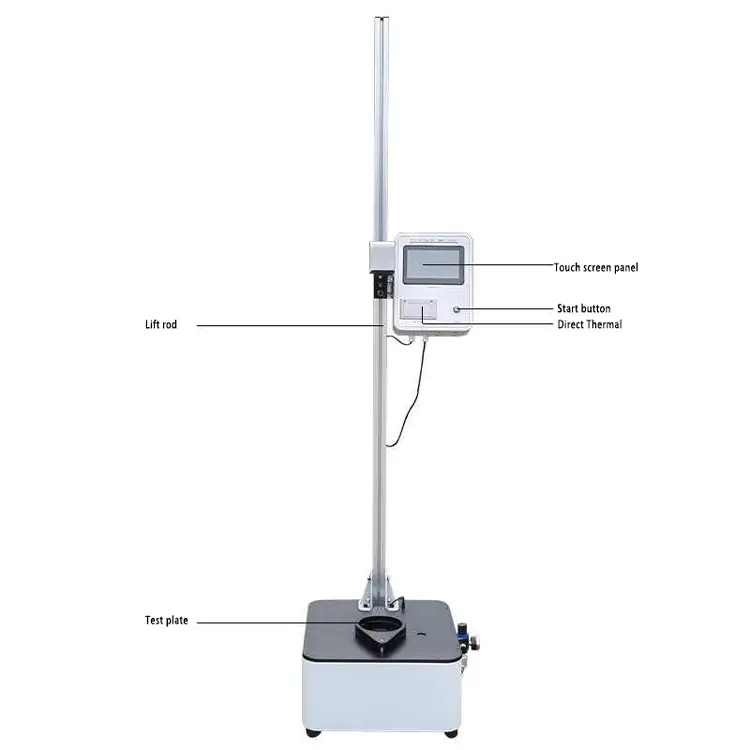

✅ User-Friendly Touchscreen Operation

-

Advanced touchscreen control system for intuitive parameter settings such as drop height, dart mass, and test mode.

-

Real-time display of impact results, failure counts, and statistics.

-

Automatic data recording, calculation, and report generation minimize manual handling.

✅ Safety & Maintenance

-

Equipped with a protective safety enclosure and two-hand operation trigger to prevent accidental dart release.

-

Pneumatic clamping system ensures the specimen is securely held in position.

-

Modular design allows easy replacement of darts, weights, and accessories for quick maintenance.

✅ Data Management & Connectivity

-

Internal memory stores multiple test records.

-

Export results via USB, RS232, or network connection for further analysis.

-

Optional software enables data tracking, statistical evaluation, and report printing in PDF or Excel format.

Technical Specifications

(Specifications can be customized according to your testing requirements.)

|

Measuring method

|

A and B (Optional)

|

|

Measurement range

|

A:50~2000g B:300~2000g

|

|

Measuring accuracy

|

0.1g(0.1J)

|

|

Test condition

|

23℃,50%RH(standard)

|

|

Sample clamping

|

pneumatic

|

|

Sample size

|

>150mm×150mm

|

|

Power

|

AC220V50Hz

|

|

Net weight

|

70kg

|

|

Contour dimension

|

A method:500(L)mm×450(B)mm×1320(H)mm

B method: 500(L)mm×450(B)mm×2160(H)mm |

|

Standard configuration

|

A method configuration

|

|

Option

|

B method configuration (Note: air users should bring by users)

|

Applications

-

Plastic film and packaging manufacturers

-

Research and development laboratories

-

Quality control and inspection departments

-

Food, pharmaceutical, and industrial packaging material testing

-

Comparative performance analysis of new material formulations

Why Choose Our Drop Dart Impact Tester?

-

Precision & Repeatability – Stable mechanical structure and high-accuracy sensors ensure consistent test results.

-

International Standards Compliance – Meets ASTM, ISO, and GB requirements for global reliability.

-

Easy Operation – Intuitive interface and automated data processing save time and minimize human error.

-

High Safety Level – Enclosed design and safety locks protect operators during testing.

-

Strong Data Support – Integrated data management for traceable quality control.

-

Customizable Options – Dart sizes, drop heights, and test methods can be tailored to your needs.

Testing Principle (How It Works)

-

Cut the film sample to the required size and place it on the clamping fixture.

-

Set the test method (A or B) and select the dart mass or initial energy level.

-

The dart is automatically released to free-fall and impact the specimen.

-

Observe whether the sample fails or remains intact.

-

Continue testing according to the staircase method until the critical impact energy is determined.

-

The system calculates the mean failure energy and generates a complete report.

Optional Accessories

-

Different dart head materials (steel, aluminum, phenolic resin, stainless steel)

-

Standard weight sets for both Method A and Method B

-

Data analysis software for PC connection

-

Calibration kits and maintenance tools

-

Optional high-energy impact configuration for thicker films

Basic operation steps:

System power→Choose experimental method→Estimates that initial impulse and Δm→System automatically

calculation progress→Automatic judgment whether meet the end conditions→Test results show→Print test

report→Off-test

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-723A TH-9001 Carbon Black Content Tester

-

RT-722 Computerized Plastic and Metal Power 10KN, 20 KN Capillary Rheometer

-

RT-719 Digital Bottles Cap Torque Testing Machine

-

RT-712B Automatic Limited Oxygen Index Tester

-

RT-706 2000mm Height Falling Ball Impact Testing Machine

-

RT-702B Digital Izod Impact Tester

-

RT-109B 10T Plastic and Foaming Rubber Flat Vulcanizing Press Machine

-

RT-129 Desktop Manual Plastic Injection Molding Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)