RT-716 High Temperature Muffle Oven for Ceramics

RT-716 High Temperature Muffle Oven for Ceramics

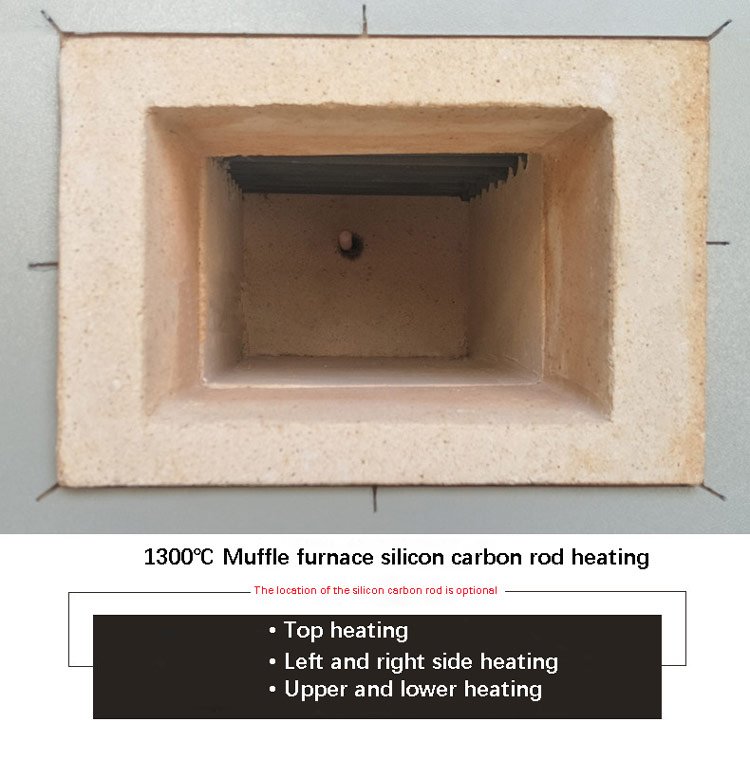

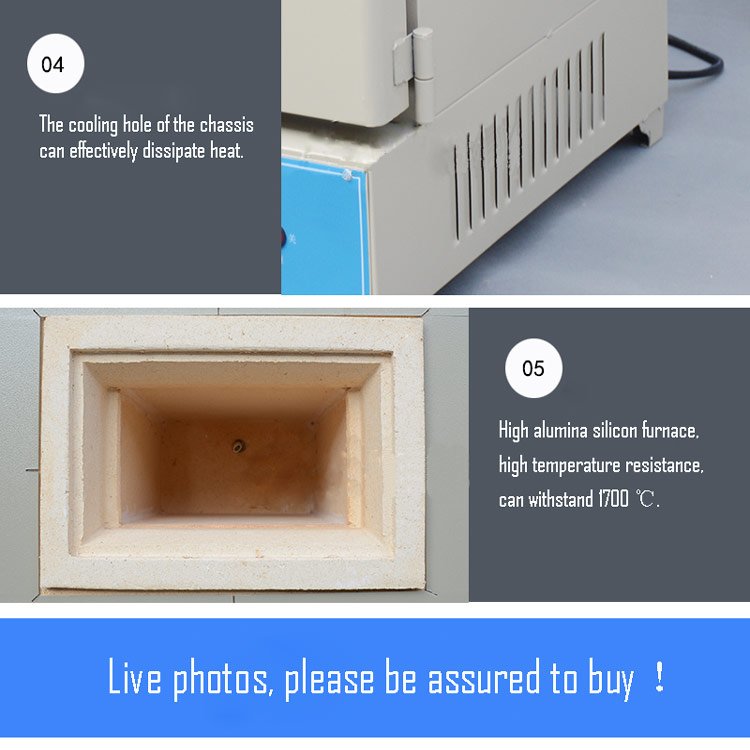

This series High temperature resistance furnace muffle furnaces are used on analysis element and measuring the function of heating and heating treatment of General small steel hardening, annealing, tempering. High – temperature furnace can also be used for metal, ceramic sintering, dissolving, analysis of high temperature heating.

Product Details:

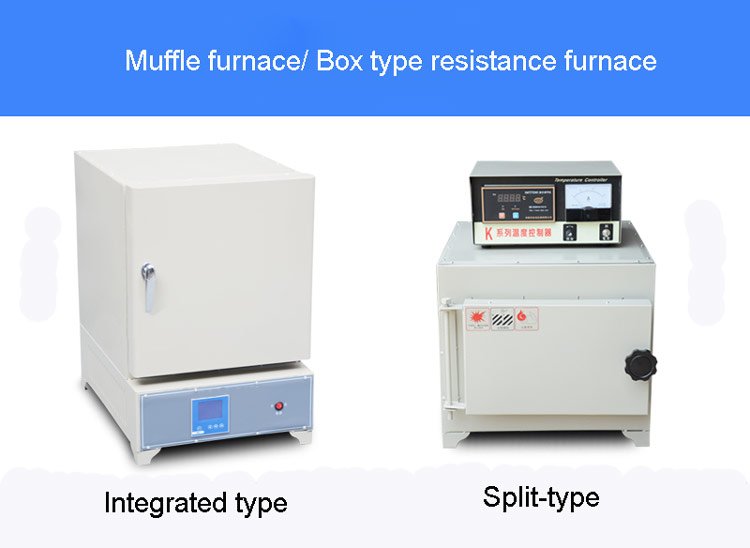

| Model | Furnace size

D*W*H(CM) |

Temperature

℃ |

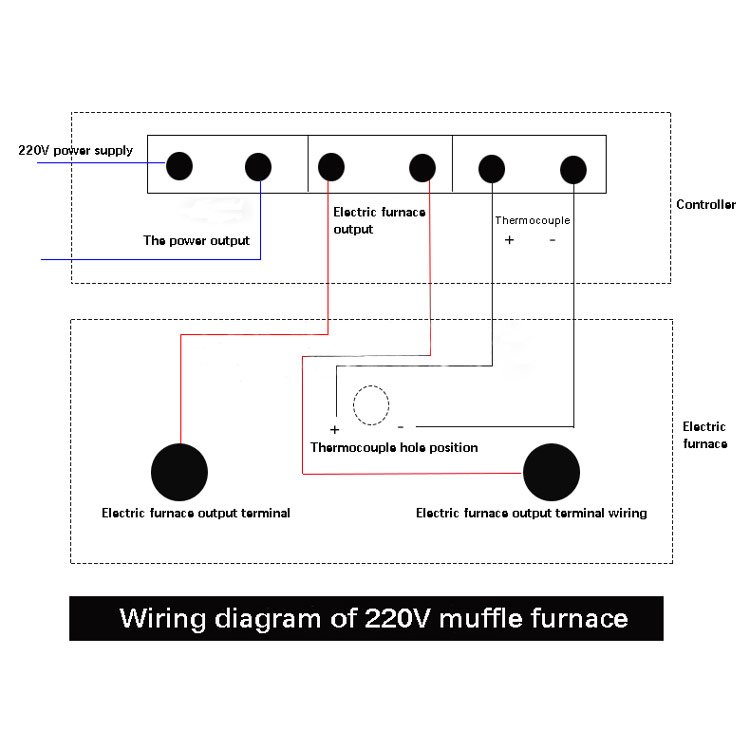

Voltage

V |

Weight

KG |

| RT716-2.5-10A | 20*12*8 | 1000℃ | 220 | split-type 50/ integrated type 70 |

| RT716-4-10A | 30*20*12 | 220 | split-type 85/ integrated type 100 | |

| RT716-8-10A | 40*25*16 | 380 | split-type 150/ integrated type 180 | |

| RT716-12-10A | 50*30*20 | 380 | split-type 200/ integrated type 250 | |

| RT716-2.5-12A | 20*12*8 | 1200℃ | 220 | split-type 50/ integrated type 70 |

| RT716-5-12A | 30*20*12 | 220 | split-type 85/ integrated type 100 | |

| RT716-10-12A | 40*25*16 | 380 | split-type 150/ integrated type 180 | |

| RT716-12-12A | 50*30*20 | 380 | split-type 200/ integrated type 250 | |

| RT716-4-13A | 25*15*10 | 1300℃ | 220 | split-type 85/ integrated type 100 |

| RT716-8-13A | 50*20*16 | 380 | split-type 50/ no integrated type | |

| RT716-10-13A | 40*20*16 | 380 | split-type 150/ integrated type 180 |

Product Description:

Customized Professional High Temperature Industrial 600 Degree Oven can be used for:

element analysis to determine the heat treatment effect of quenching, annealing and tempering of small steel pieces.

Sintering of ceramics;

Ash test requiring high temperature heating.

Applicable to industrial and mining enterprises, colleges and universities, laboratory research units and so on.

(for testing plastics, rubber ash, heating furnace with silicon carbon rod, recommended model: rt-716-4-13a)

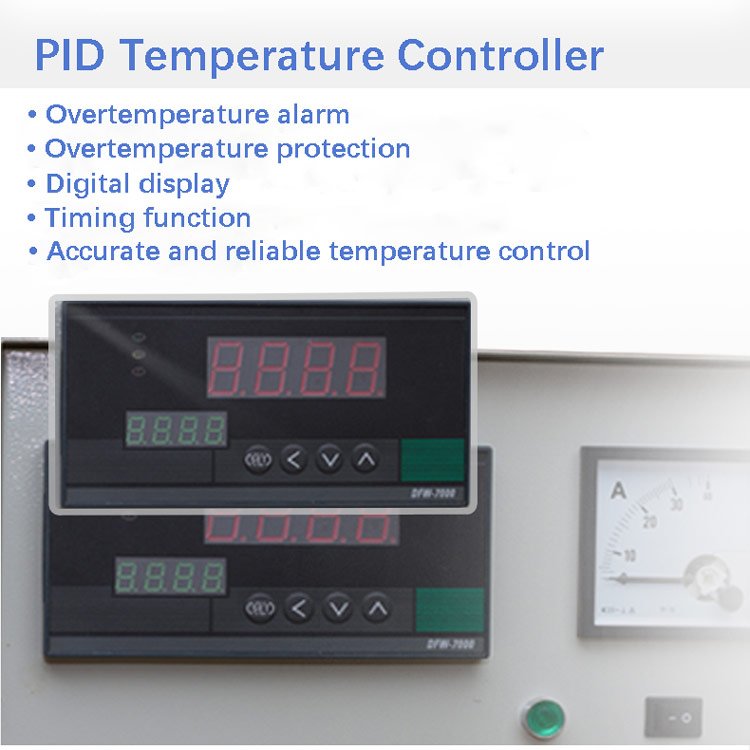

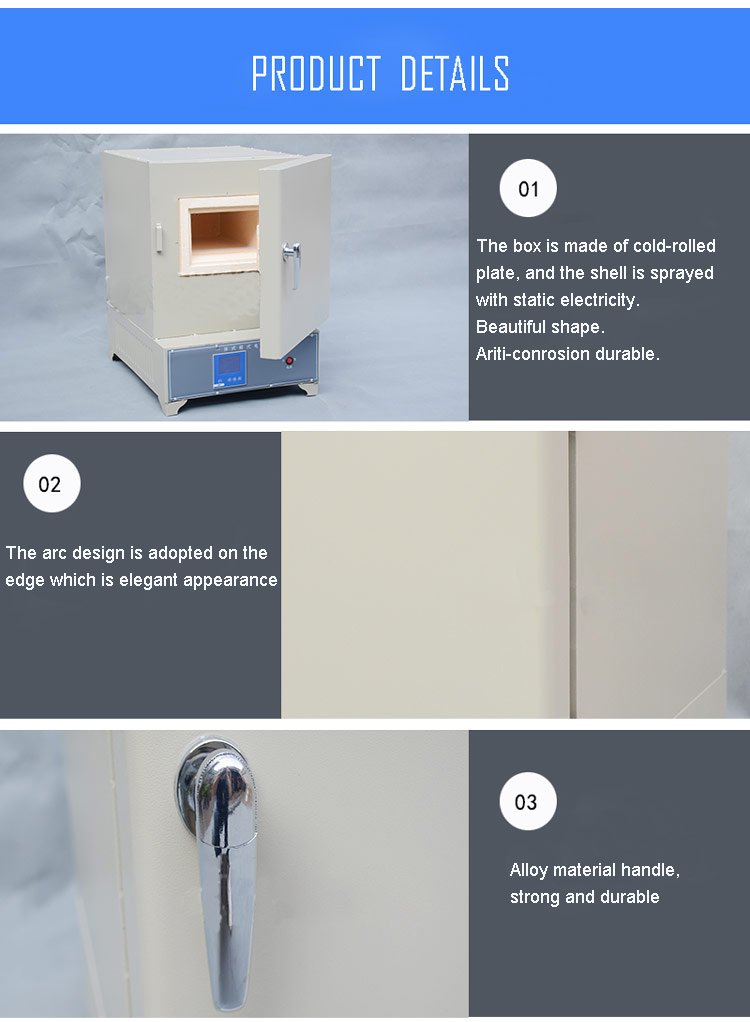

Main feature:

The resistance furnace with modern high – tech technology, temperature error ± 2 °C, precision temperature control ± 2 °C. Main parts adopt imported material, shell is advanced CNC machine tooling, imported luxury, beautiful two – color epoxy powder electrostatic painting processes, furnaces using a special light material and it. The indicators have reached the international advanced level.

Main usage:

Primarily for ceramics, glass, enamel, and inorganic pigments, industrial and mining enterprises and scientific research on abrasive frit glaze, glass, low – temperature flux, used in enamel and bond test, also for alloys, composite materials, melting, physical and chemical experiments.

Apply industry:

It can be use on determination, metallographic laboratory for analysis, research, or industrial and mining enterprises for high – temperature sintering and metal work in the air for normalizing, annealing, hardening, for the Laboratory for universities, scientific research and environmental protection unit.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

Low Frequency Electromagnetic X Y Z Vibration Test Table (RT-1301)

-

RT-308A Desktop UV Accelerated Aging Testing Chamber

-

RT-315 Programmable Laboratory Electronic Part Dustproof Test Chamber

-

RT-311 Salt Spray Corrosion Testing Chamber

-

RT-310 Thermal shock impact testing chamber

-

RT-308 ISO 20340 UV Simulate Environmental Solar UV Accelerated Aging Testing Chamber

-

RT-306 China Supplier Laboratory High Temperature Electric Drying Oven

-

RT-302 Desktop Constant Temperature and Humidity Test Chamber

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)