RT-308A Desktop UV Accelerated Aging Testing Chamber

RT-308A Bench UV Accelerated Aging Testing Chamber

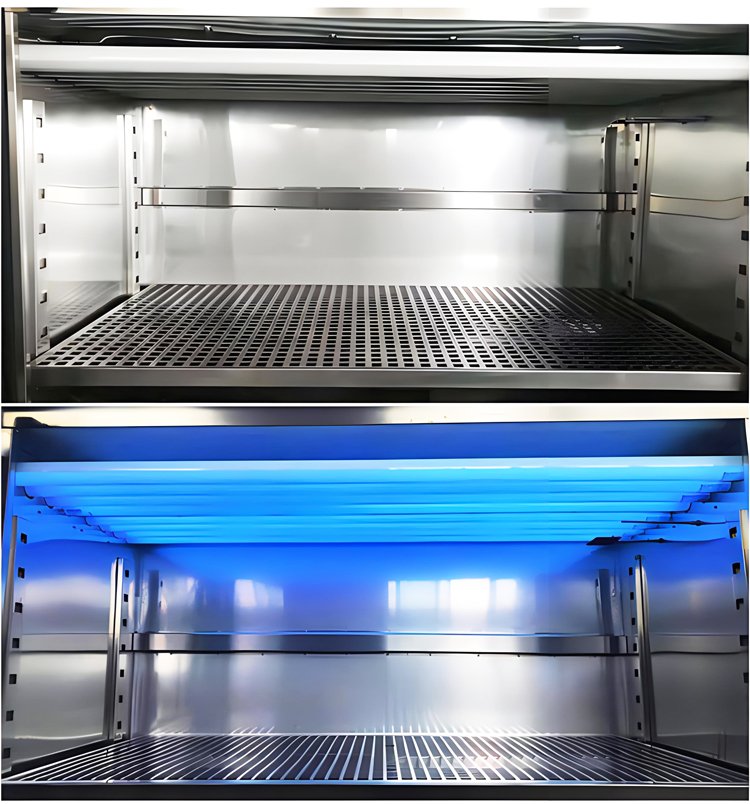

UV test machine, the UV lamp can simulate the effect of the sun and condensation, and the water spray system can simulate the effect of rain and dew. The temperature can be controlled at the process of testing. A typical test cycle usually tests at UV radiation of high temperature and 100% humidity in the dark. It is typically used in paint and coatings, automotive, plastic products, wood products, glue, etc.

Product Details:

Equipment summary:

RT-308 UV Accelerated Aging Testing Chamber can simulate the sun, rain, and dew to damage the material; UV using UV lamp simulates the effect of sunlight, cold rain, and dew. Being tested, materials are placed in a certain environment in which the light and moisture are alternating. The materials are tested for several days or weeks, you can know the damage of material at outside for several months or several years, Damage types include: bleaching, discoloration, loss of light, powder, crack, turbidity, bubble-based, embrittlement, strength decline and oxidation.

Main functions:

In the UV test machine, the UV lamp can simulate the effect of the sun and condensation, and the water spray system can simulate the effect of rain and dew. The temperature can be controlled during the testing process. A typical test cycle usually tests at UV radiation of high temperature and 100% humidity in the dark. It is typically used in paint and coatings, automotive, plastic products, wood products, glue, etc.

Corresponding standard:

Accord with ASTMG53-77, GB﹑GJB﹑MIL﹑ASTM﹑CNS﹑IEC﹑JIS﹑AATCC﹑DIN﹑Fed Test﹑BS﹑SAE

Applicable industries:

It is widely used in paint, resins, plastics, printing and packaging, aluminum, adhesives, auto, cosmetics, metals, electronics, electroplating, medicine, etc.

Technical parameter:

|

Name

|

Desktop UV Weathering Test Chamber

|

|

Light Source

|

15W UV-B ultraviolet

|

|

Box material

|

All stainless steel

|

|

Center distance between lamps

|

150mm

|

|

UV temperature

|

RT~60℃

|

|

Workshop size

|

W400XD320xH350(mm)(can be customized )

|

|

Sample stand

|

Liftable (the distance between the lamp and the sample is adjustable).

|

|

Function Selection

|

Select the cycle function for continuous and cyclic options when the light and dark times are adjustable.

|

|

Timing

|

Maximum timing 9999H(with power outage hold function, continue to work after power restoration).

|

|

Volume (W x D x H)

|

680x350x435(mm)

|

|

Power

|

110V/60Hz,16A or 230V/50Hz, 9A,1800W(max)

|

RT-308B Touch Screen Type UV Test Machine

Main feature:

1, simulated sunlight

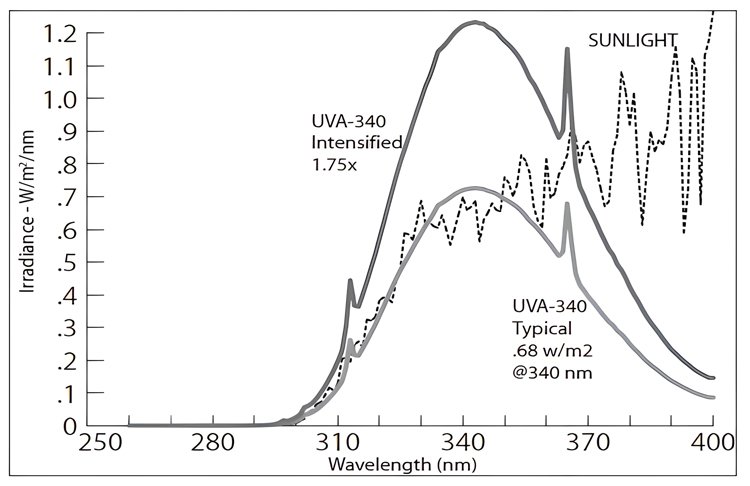

The sun’s ultraviolet rays mainly cause damage to material durability. We use UV lamps to simulate sunlight in the ultraviolet part of the short wave; it produces very little visible or infrared spectral energy. We can choose according to different testing requirements of various wavelengths of UV ultraviolet light because the total energy and wavelength of UV radiation are not the same in each lamp. Usually, UV lamps can be divided into two kinds UVA and UVB.

2, UV lamp type

UVA-340 lamp: UVA-340 lamps can simulate short-wave UV light in the sunlight excellently, i.e., sunlight from 365nm to 295nm cutoff wavelength.

UVB-313 lamps: UVB-313 lamps are usually issued by short-wave UV radiation than the Earth’s surface in the strong solar ultraviolet radiation, which can speed up the greatest degree of material aging. However, the lamp may have caused some of the material not to meet the actual damage. The UVB-313 lamp is mainly used for quality control and research and development or on the wearability of materials to run the test.

UVA-351 lamp: Simulation of UV sunlight through windows; it is the aging of indoor materials for testing the most effective.

3, moisture condensation environment

In many outdoor environments, the material wet daytime can be up to 12 hours. The results show that this result is the main factor of outdoor wet dew, not rain—UV condensation through a unique function to simulate outdoor wet erosion. During the test cycle, water is heated at the bottom of the reservoir to generate superheated steam to fill the entire test chamber. Hot steam in the test chamber is maintained at 100% relative humidity and a relatively high temperature. The sample is fixed in the test room wall, so the test sample surface is exposed to ambient air in the test room. The outward face of the sample exposed to the natural environment has a cooling effect, leading to internal and external surface of the sample with temperature, the temperature difference causes the appearance of the sample in the whole process of condensation cycle, the test surface always have condensation of liquid water generated.

Because exposure to humid outdoor exposure time is up to ten hours a day, so a typical condensation cycle usually lasts several hours. UV offers two moist simulations. The condensation method is the most widely used, which simulates the best way of outdoor wet erosion. All models can be run UV condensation cycle. Because some applications require the use of water spray to achieve practical results, some condensation cycle UV models can be run either in the water spray cycle.

4, the temperature control in each cycle: the temperature can be controlled at a set value.

At the same time, the board can monitor the temperature of the thermometer. Higher temperatures can accelerate the aging process, while temperature control for the reproducibility of the test is also very important

5, For some applications, the water spray system can better simulate the end use of the environmental conditions.

Water spray in a simulated drastic change in temperature and rainfall caused by thermal shock or mechanical erosion is very effective. Conditions in some practical applications, such as sunlight, heat, and the stroke of showers, dissipate rapidly; the material will undergo dramatic changes in temperature, thermal shock, and thermal shock for many materials. This is a part of the test. UV water spray to simulate thermal shock and/or stress corrosion. The sprinkler system has 12 nozzles, each side in the test room of 6; the sprinkler system can run a few minutes and then shut down. This short cooling water samples quickly and creates thermal shock conditions.

6, irradiation intensity control:

Optional matching light intensity control options are available to accurately type and reproduce results; the light intensity control system allows users to set different requirements for different test light intensities. Feedback loop devices, through its precise control of light intensity, but also can extend the life of fluorescent lamps.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

ASTM ISO Standard Box-Type UV Aging Chamber with Touch Screen Simulation Sunlight Rain and Dew Test Equipment (RT-308B)

-

ASTM D5423 Air Ventilation Aging Climatic Test Chamber (RT-326)

-

RT-318 Laboratory Battery Temperature Humidity and Vibration Test Machine

-

RT-317 Circulating Water Bath 6 Hole Constant Temperature Water Bath

-

RT-314 IPX4 / IPX 5 / IPX6 / IPX7 / IPX8 / IPX9K Waterproof Rain Test Equipment

-

RT-308 ISO 20340 UV Simulate Environmental Solar UV Accelerated Aging Testing Chamber

-

RT-305 Aging Anti-Yellow Testing Chamber

-

RT-302 Desktop Constant Temperature and Humidity Test Chamber

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)