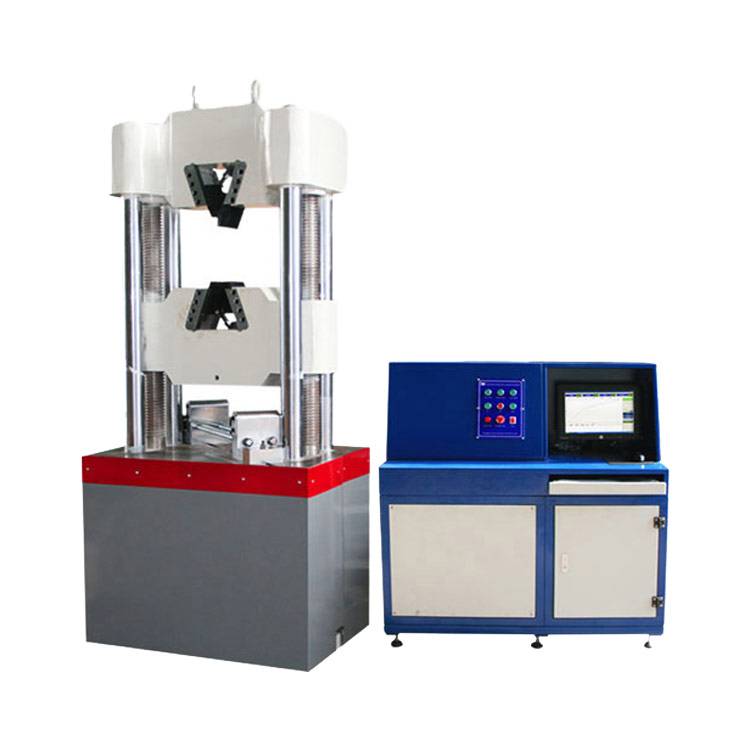

RT-210A 2400KN electro-hydraulic servo universal testing machine

RT-210A The host of computer-controlled electro-hydraulic servo universal testing machine adopt oil cylinder mounted under the host, mainly for metals, non-metallic tensile, compression and bending test. Used in metallurgy, construction, light industry, aviation, aerospace, materials, universities, research institutes and other fields.Test operations and data processing in line with GB228-2002 “metal material tensile test method at room temperature” requirements.

Product Details:

Introduction:

RT-210A The host of computer-controlled electro-hydraulic servo universal testing machine adopt oil cylinder mounted under the host, mainly for metals, non-metallic tensile, compression and bending test. Used in metallurgy, construction, light industry, aviation, aerospace, materials, universities, research institutes and other fields.Test operations and data processing in line with GB228-2002 “metal material tensile test method at room temperature” requirements.

Host:

Adopt oil cylinder under mounted type host, stretching space is at the top of host, compression test space is between the at the work table and the crossbar .

Transmission system:

Down beam go up and down by the use of motor reducer, chain drive mechanism, vice screw drive, to achieve tensile, compression of space to adjust.

Hydraulic System:

The hydraulic oil in the tank through motor drive high-pressure pump into the oil, flows through check, high pressure oil filters, differential pressure valve set, servo valves, into the oil cylinder.Computer control signals to the servo valve, the control and direction of the servo valve opening to control the flow into the cylinder to achieve constant test force, constant displacement control.

through the tubing, pressure tubing through and through oil return valve to tank.

Control system:

- Support for tensile, compression, shear, bending and other tests;

- Support open editing test, editorial standards and editorial procedures, and to support export import testing, standards and procedures;

- Support custom test parameters;

- Adopt an open statement in the form of EXCEL, to support user-defined report format;

- Print the query testing results flexibility, support for printing multiple samples, custom sorting print projects;

- Procedure supports hierarchical management levels (administrator, tester) user management rights;

Safety protection device:

- a) When the test force more than 3% of the maximum test force, the overload protection, oil pump motor shut down.

- B) When the piston rises to the upper limit position, stroke protection, pump motor shut down.

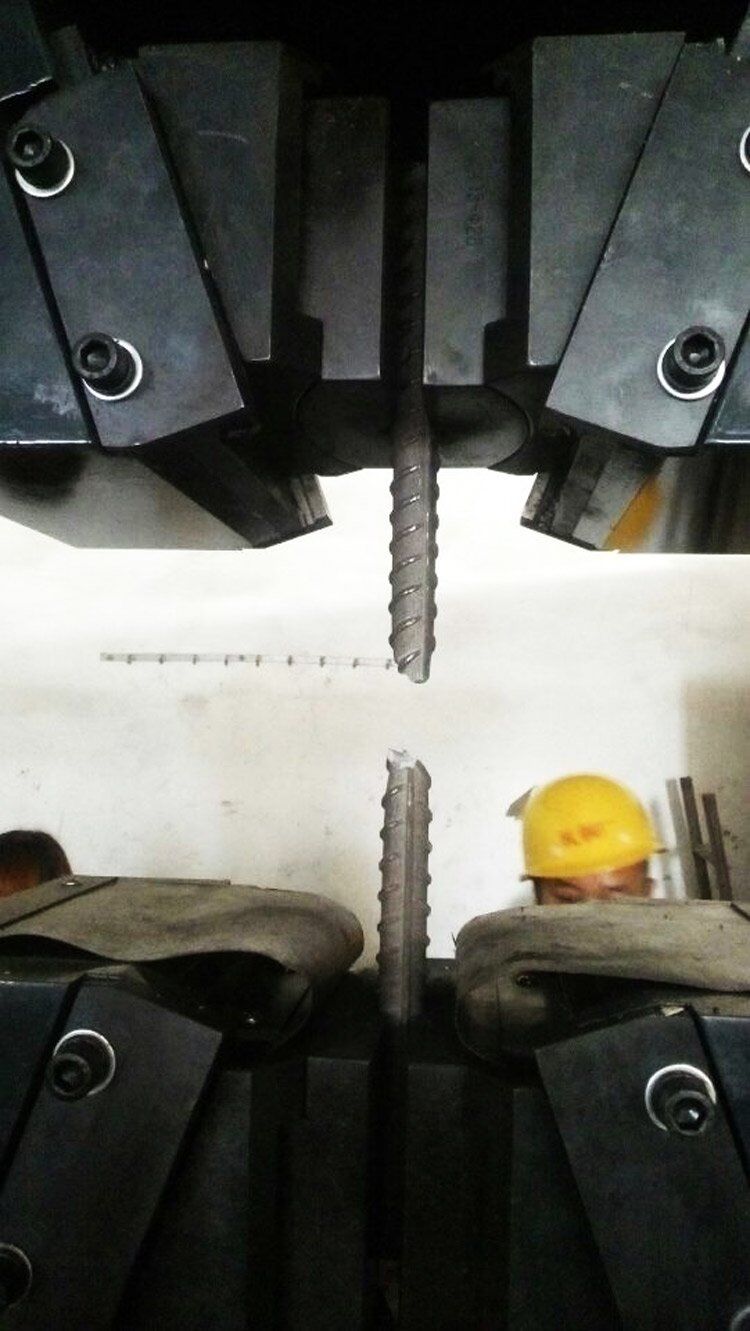

Fixture:Whole set fixtures include:stretch fixture,compression fixture,bending fixture.

Main performance technical specifications:

| Max load KN | 100 | 300 | 600 | 1000 | 1200 | 2400 | ||||||

| Test force measuring range KN | 2%-100%FS | |||||||||||

| Test Force showed the relative error | ≤indicating value±1% | |||||||||||

| Test Force Resolution | 0.01kN | |||||||||||

| Displacement measurement resolution mm | 0.01 | |||||||||||

| Deformation measurement accuracy mm | ±0.5%FS | |||||||||||

| Maximum tensile test space mm | 550 | 650 | 750 | 900 | 1000 | |||||||

| Max compression space mm | 380 | 460 | 700 | 900 | ||||||||

| Diameter of round specimen clamp jaw mm | Φ6-Φ26 | Φ13-Φ40 | Φ13- Φ60 | Φ15-Φ70 | ||||||||

| Thickness of flat specimen clamping jaws mm | 0-15 | 0-15/15-30 | 0-40 | 0-70 | ||||||||

| Maximum clamping width of the flat specimen mm | 70 | 75 | 125 | 80 | ||||||||

| Maximum clamping width of the flat specimen(Column number) | 2 | 2/4 | 4 | |||||||||

| Shear specimen diameter mm | 10 | |||||||||||

| Upper and lower compression plate size mm | Φ160(option 204×204) | |||||||||||

| Clamping method | Manual | Automatic | ||||||||||

| The maximum distance between the fulcrum bending | 450 | — | ||||||||||

| Space stretching from the two pillars distance | 450 | 450/550 | 700 | 850 | ||||||||

| Pump motor power KW | 1.1 | 1.5 | 3 | |||||||||

| Beam moves up and down motor fixed rate KW | 0.75 | 1 | 1.5 | |||||||||

| Net weight Kg | 1700 | 1900 | 2600 | 3300 | 5000 | 10000 | ||||||

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

2KN Desktop Type Fabric Tensile Strength Tester with Pneumatic Jaws (RT-202A)

-

RT-204C Universal Testing Machine With Extensometer

-

RT-204D High and Low Temperature Bending Tensile Testing Machine

-

RT-211 Computer Type Servo Hydraulic Horizontal Universal Testing Machine

-

RT-209A Steel strand electro-hydraulic servo-type testing machine

-

RT-209B 1000kN Digital Display Hydraulic Universal Testing Machine

-

RT-208 1000kN Hydraulic universal material testing machine

-

High Low Temperature Universal Material Testing Machine (RT-204D)

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)