RT-109D Manual Vulcanizing Press Machine

RT-109D Manual Vulcanizing Press Machine

This series of flat vulcanizing machines are used for the main equipment for pressing and molding various rubber model products and non-model products, and can also be used for pressing various thermosetting plastics and foaming rubber and plastic products. With independent power mechanism and electrical system, centralized control by buttons. Working pressure and heating temperature can be adjusted within a certain range. This model is manual.

Product Details:

Equipment Description:

This series of flat vulcanizing machines are used for the main equipment for pressing and molding various rubber model products and non-model products, and can also be used for pressing various thermosetting plastics and foaming rubber and plastic products. With independent power mechanism and electrical system, centralized control by buttons. Working pressure and heating temperature can be adjusted within a certain range. This model is manual.

Technical Parameter:

- Capacity: 5-20ton (adjustable)

- Temperature range: normal temperature to 300 ℃

- Temperature accuracy: ± 1.5 ℃

- Temperature controller: LED digital display

- Temperature control mode: LED mode control

- Heater: electric heating tube heating

- Working mode: electric heating. Heating method: electric heating.

- Heating time: about 15min from normal temperature to 160 ℃ (heating speed can be adjusted)

- Timer: LED display, 0.01S ~ 999min ~ 999hr (adjustable)

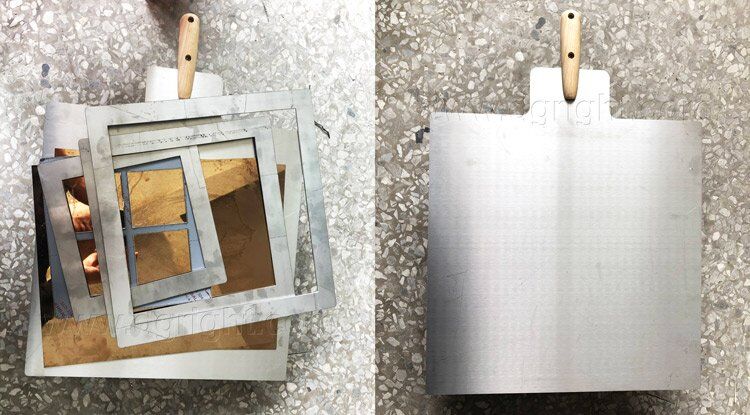

- Hot pressing plate: 300 × 300mm (specially processed high hardness steel plate)

- Exhaust function: manual [semi-automatic]

- Hydraulic system: manual hydraulic cylinder,

- Cylinder stroke: Max 150mm

- Oil cylinder speed: 5mm / s

- Pressure table: 0 ~ 200kg / sq.cm

- Body Product: (W × D × H) 420 × 450 × 1100 mm

- Electricity source: 3∮, AC220V, 5A

- Weight: about 400kg

Operate Method:

- First, adjust the test machine horizontally, use the spirit level to place on the base of the machine, and adjust the basic screws to level according to the instructions of the spirit level (adjust when installing the machine or moving the machine).

- Turn on the main power switch to make the power pass through the control panels of the machine.

- Set the test temperature.

- Set the temperature of the upper, middle, upper, lower, and lower molds according to the requirements of the model. After the temperature reaches the set temperature, open the cylinder door, and place the isolation stainless steel plate and pattern.

- Start the test button to make the hydraulic cylinder press up to start the test (do not adjust the pressure and speed of the hydraulic system at will).

- The system will reset automatically when the set time is reached.

- Observe the style and the test is over.

Precautions and maintenance

4.1 Notes:

4.1.1. The power of the display and motor of the machine is input according to the label.

4.1.2. The operator must be familiar with the operation and maintenance methods of the machine and pay attention to its use.

4.1.3. The storage environment must be kept clean and not wet.

4.1.4. When necessary, please pay attention to the handling and do not damage the parts.

4.1.5. Care must be taken when replacing the fixture to prevent it from falling and hurting the parts.

4.1.6. Periodically inspect the drive belt for looseness and adjust it.

4.1.7. Please apply for inspection and calibration regularly to ensure accuracy.

4.2 Maintenance items:

4.2.1. Machine parts, the appearance is often wiped to keep clean.

4.2.2. Please wipe the electroplated part with oil to prevent rust and keep it bright.

4.2.3. Please add lubricating oil to the power screw and screw part to ensure the sensitivity of the transmission. (The lubricating oil can be mixed with butter and a little engine oil).

4.2.4. Please wipe the panel (control box or display) with a dry cloth to prevent water from damaging the IC electronic parts.

4.2.5. Please place all fixtures and joint accessories properly, and wipe the anti-rust oil to prevent rust.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-726 ESCR Environmental Stress Cracking Resistance Tester

-

Free-Falling Dart Impact Tester for Plastic Films & Packaging Material (RT-720)

-

RT-712B Automatic Limited Oxygen Index Tester

-

RT-707 Plastic Pipe Drop Hammer Impact Test Machine

-

RT-705 Plastic Temperature Deflection Vicat Softening Test Apparatus

-

RT-702B Digital Izod Impact Tester

-

RT-110D Desktop Small Two Roll Mill

-

RT-109B 10T Plastic and Foaming Rubber Flat Vulcanizing Press Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)