RT-109B 10T Plastic and Foaming Rubber Flat Vulcanizing Press Machine

RT-109B 10T Plastic and Foaming Rubber Flat Vulcanizing Press Machine

This series of flat vulcanizing machine is the main equipment that can be used in pressing all kinds of rubber model product and non-model product. In addition, it also can be used in pressing all kinds of thermosetting plastic and foaming rubber and plastic product.

Product Details:

Equipment Description:

This series of flat vulcanizing machine is the main equipment that can be used in pressing all kinds of rubber model product and non-model product. In addition, it also can be used in pressing all kinds of thermosetting plastic and foaming rubber and plastic product. With independent actuating unit and electric system, apply button centralized control. Within certain limits, working pressure and heating temperature can be adjusted. This kind of model, can be classified manual operate and semi-automatic operate. The flat vulcanizing machine with the function of a high degree of automation, easy operation,energy conservation and environment protection, and also superior performance.

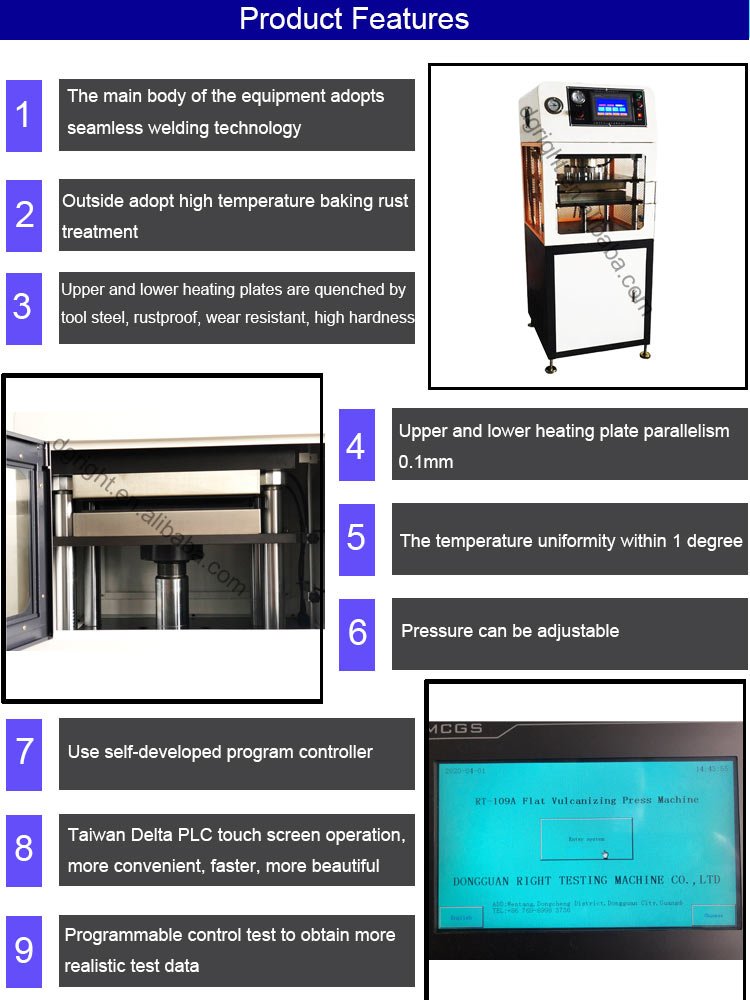

Main Features:

1.Controlled by PC or manual, performance reliable, high degree of automation. Can automatically identify the wrong command,so avoid the accidence which caused by wrong operation.

2.The preprogrammed process can be locked, the operator can not change without authorization, so that guarantee the quality of pressed product.

3.With the function of timing open mold, automatically exhaust and reinforcing pressure,etc.

4.Optional: Manual operating or Automatic operating mode

5.Electrical heating pressing machine apply digital display(or pointed type) to control temperature, and control and display the heating plate temperature.

Application:

It mainly used in producing vulcanizing parallel adhesive type, such as conveyor belt,driving belt, and pressing rubber products, foamed plastic,thermosetting plastic(bakelite) and other plastic products. It also suitable for O ring,the key products such as cell phone, keyboard,remote-control,sealing washer such as pressure cooker, electric cooker, mechanical accessories for household, food, health and medical treatment. At the same time,this machine alsocan be used in complex silicone and rubber fittings production and process, such as nipple,medical supplies, health product, artware, toy seal, electroconductive rubber, automotive rubber parts, industrial rubber parts,medical silicone product, sport equipment, all kinds of vessels, multilayer product and so on.

Introduction:

Flat vulcanizing machine is mainly used in vulcanizing flat belt(such as conveyor belt,driving belt). It is a kind of hydraulic machine. The main function of flat vulcanizing machine is providing the pressure and temperature for vulcanization. The pressure is generated from hydraulic system by hydraulic cylinder, and the temperature provided by heating tube. The control part of flat vulcanizing machine is mainly consist of high and low pump motor on hydraulic station,magnetic valve,vulcanization time,motion instructions and alarm function, etc.

Technical parameter:

|

Parameter Capacity |

10T |

| Temperature range | Normal temperature~300℃ |

| Temperature precision | ±2℃ |

| Temperature controller | LED button type control mode and PLC touch-screen programmed control mode |

| The method of temperature control | LED button type control temperature or PLC touch-screen programmed control temperature |

| The way of heating | Electric heating |

| Heating up time | 0~30min |

| Timer | LED display or PLC touch-screen displayer |

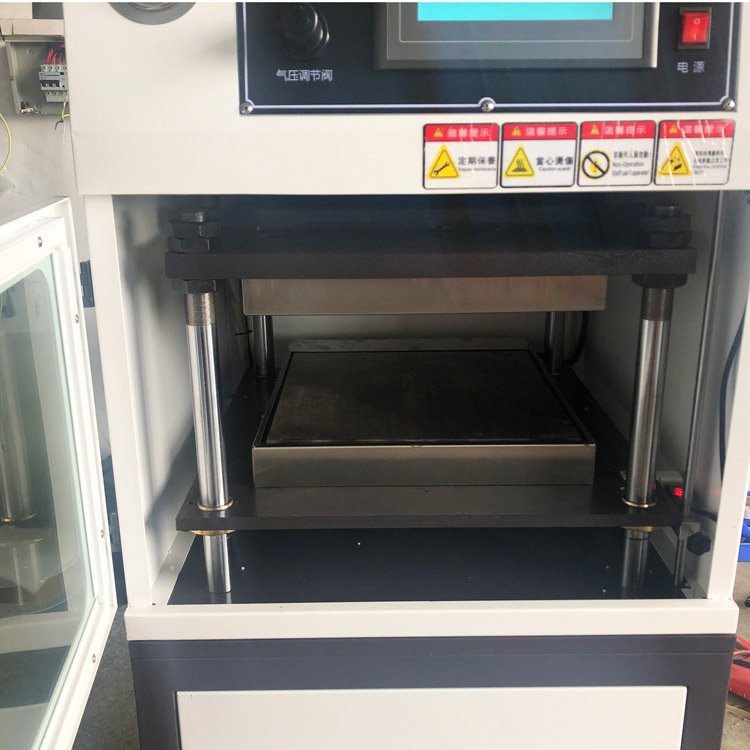

| Heating plate size | 350x350mm or customize |

| The number of heating plate layers | Single-layer |

| The max.distance between up and lower heating plate | 150mm |

| The min.distance between up and lower heating plate | 150mm |

| Exhaust function | Low pressure automatically exhaust 3~10 times per minute (Adjustable) |

| Stroke | Max 150mm |

| Pneumatic pressure | 0~8kg/cm2 |

| Pressure | 220V,50/60HZ(or 50HZ) |

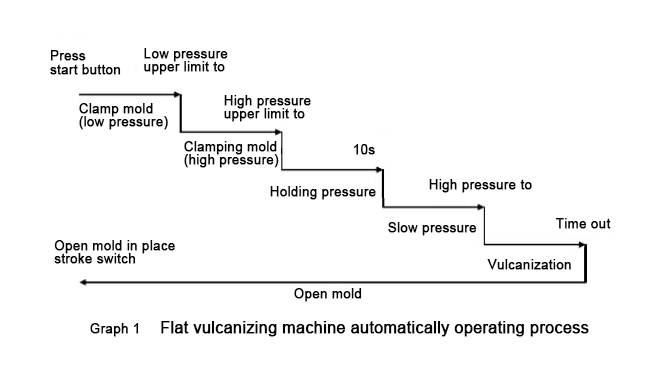

1.The system including two kinds of operating mode: automatical and manual.

2.During manual running: Turn on opening mold, stop opening mold, turn on clamping mold, stop clamping mode by pressing button, to finish the manual control for opening and clamping mold.

3.Automatically operating process showed as below。Solenoid valve, and others are vulcanizing time,motion instruction and alarms, etc.

- Action execution instruction:

a)The process of clamping mold is finished by two low pressure(11KW) pumps and a high pressure(18KW) pump, the hydraulic system drives the lower mold to do the upward movement,when the pressure achieve to the low pressure limit(12MPa), the low pressure pump will stop; When achieving high pressure limit, the high pressure pump will stop, and the whole process finished.

b)During holding pressure, due to use check valve in the hydraulic circuit, so no need to the hydraulic pump work, and keep the pressure of hydraulic system, the holding pressure process finished after 10s.

c)The slow pressure process consist of open mold motor(2.2KW), open mold solenoid valve and high pressure pump. When access to slow pressure step, firstly, the open mold motor and open mold solenoid valve will finish decompression. When the pressure achieve to 0 Mpa, the opening mold motor and open mold solenoid valve will be outage,the high pressure pump will power on and clamp force, when achieve high pressure limit, the high pressure pump will stop and repeat three times, then slow pressure process done.

d)After slow pressure process, access into vulcanizing stage. Similar with holding pressure, but due to longer time(30~45min, different material will be different, time adjustable), the pressure will drop, when the pressure lower than pressure limit limit(16Mpa), will ask for turn on high pressure pump to reinforce pressure until the pressure up to high pressure limit.

e)Open mold is finished by open mold motor, open mold solenoid valve. When the lower mold drop to start position( Controlled by open mold in place stroke switch), the open mold done.

5)Vulcanizing temperature is provided by steam, the boiler produce steam, then access to vulcanizing machine uninterruptedly by manual valve.

6)System setting includes total stop button, open mold instruction button, clamp mold instruction button, vulcanization finish alarm button, and the necessary protect device such as short circuit and overload, etc.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-718 TGA/DTA/DSC Synchronous Plastic Thermogravimetric Analysis Differential Thermal Analyzer

-

RT-710 UL94 Flammability Combustion Test Chamber For Plastic(Vertical and Horizontal flame)

-

RT-709 Automatic Sample V Notch Cutting Cutter Machine for Plastic

-

RT-708 Hose Hydrostatic Pressure Burst Testing Machine

-

RT-110D Desktop Small Two Roll Mill

-

RT-109D Manual Vulcanizing Press Machine

-

RT-703C 5J Digital Charpy Impact Tester

-

RT-129 Desktop Manual Plastic Injection Molding Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)