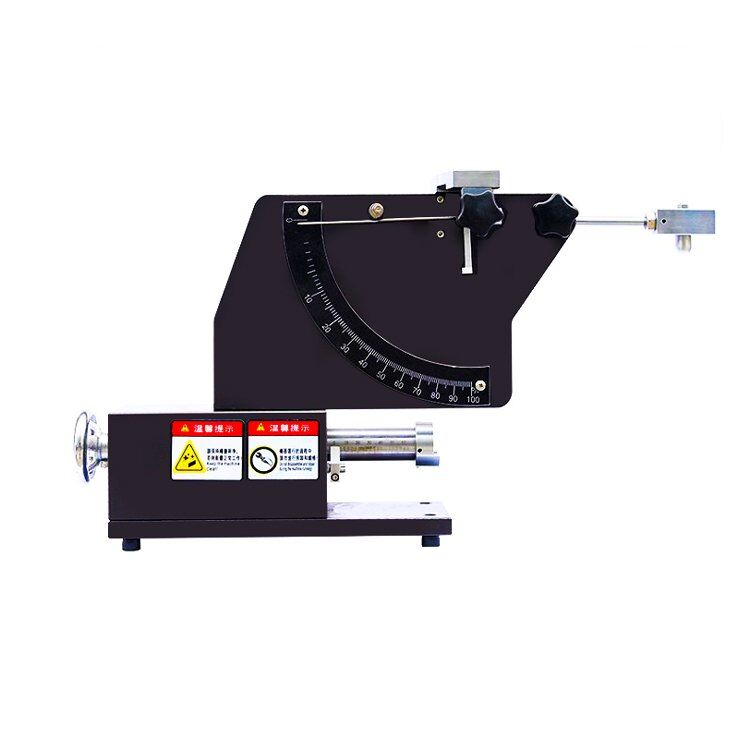

RT-108B Rubber Rebound Resilience Impact Tester

RT-108B Rubber Rebound Resilience Impact Tester

Main feature:

1. Hand-toggle release for easy operation;

2. Durable powder-coated and anodized finish;

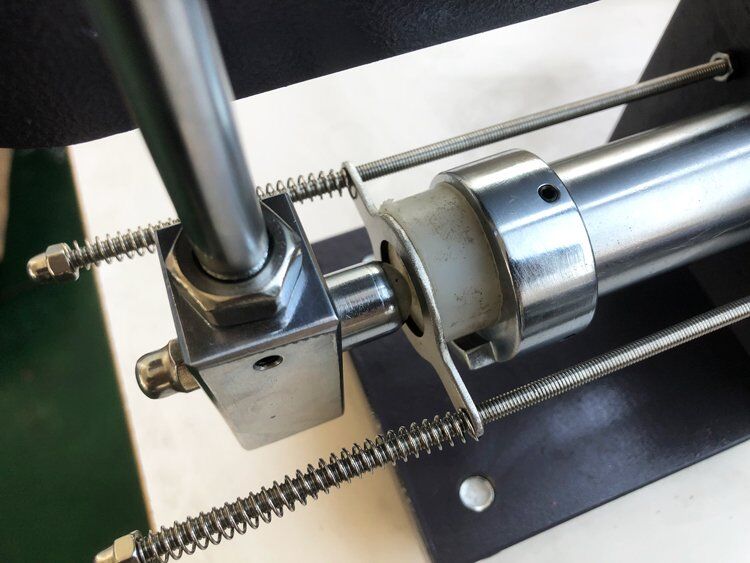

3. Mechanical parts made of non-corrosive construction and stainless steel materials;

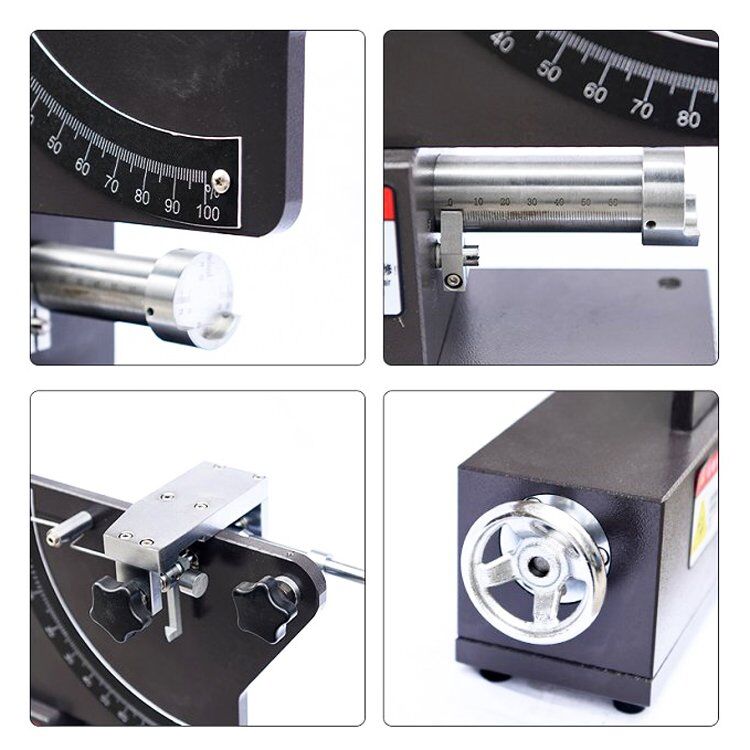

4. Laser scale fonts for clear observation and easy direct vision;

5. Four-leg level movable adjustment;

Product Details:

Equipment Overview:

The machine is energy 0.5J /1J pendulum-type impact testing machine flexibility for nominal hardness 30-85IRHD rebound between the value of vulcanized rubber.

To meet the standards:

This is in line with GB / T 1681 “Determination of vulcanized rubber elasticity” and the requirements of ISO4662 standards.

Applicable industry:

Rubber

Technical parameter:

| Model | RT-108B |

| Instruction Range | 0~100﹪ |

| Marking scale | 1﹪ |

| Adjustable range of specimen thickness | 0~60mm |

| Scale mark | 1mm |

| Measuring elastic feeding device test | Flexible test material measuring device (in line with DIN53512 and ISO4662 specifications) |

| Dimension | 62*12*33cm |

| Weight | 38kg |

Test Procedure

1. Sample preparation

Sample preparation and specimen size use a test piece with a thickness of d = 12mm and a diameter of 29 mm to 33 mm. The test sample should be vulcanized or cut directly from the finished product. Pay particular attention to the smooth and planar parallelism. Some talcum powder should be puffed slightly if the hammered surface is tacky. If a specimen of the required thickness cannot be obtained from a finished product, the specimen can be stacked, but a maximum of three pieces can be stacked. The stack can only be used for test samples that are parallel in the plane or equal in thickness across the entire surface. Samples must not contain fabrics or other reinforcing materials. If the surface is not uniform, it should be ground using DIN ISO 4661-1.

Note: When the sample thickness is thin, the sample will be affected by the stiffness of the anvil and its deformation; this can only get a small rebound value. An ISO/TC 45/WG 5 working group conducted an international comparative test in 1970. The difference in elasticity between 2 mm and 12 mm thickness was 2 to 6 %. This difference depends on the thickness of the elastomer, and for extremely soft elastomers, the difference is greatest.

2. Number of samples

At least two specimens.

3. Pretreatment of Samples

The test should be carried out at least 16 hours after vulcanization but not later than four weeks. At least for the last 3 hours of this period, the sample should be parked at a temperature of 23 ± 2 °C. For finished products, the time between vulcanization and the start of the test should not exceed three months. Otherwise, the test should be carried out within two months after delivery to the user.

4. Test procedure

After the sample was placed on the fixture on the anvil and the temperature was adjusted, the pendulum was dropped from the horizontal position to the same position on the sample for a total of 6 drops. Hold the sample before each impact. The first three shocks were used to adjust the specimen mechanically and read the resilience values of the fourth, fifth and sixth times. Take the value from three readings.

5. Evaluation

The median value is obtained from the three single measurement readings rounded off to integer percentages. The arithmetic mean of the resiliency R is calculated from the median of at least two specimens.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-133 Rubber Compression Heat Generation Flexometer Testing Machine (ASTM-D623)

-

RT-109F Vacuum Vulcanizing Machine For Silicone Products Line

-

RT-113A Vulcanized Rubber Distortion of Permanent Compression Testing Machine

-

RT-112 Rubber Hose Friction Tester

-

RT-108 Rubber Compression Rebound Tester

-

RT-107 Digital Rubber Akron Abrasion Machine

-

RT-110A Rubber Two Roll Mill Machine (electrical heating)

-

Rubber Moving Die Rheometer MDR Rotorless Curemeter Price (RT-101)

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)