ASTM G99 Pin On Disc Tribometer Wear Testing Machine (RT-228)

Multi-Specimen Four Ball Vertical Universal Wear Tester

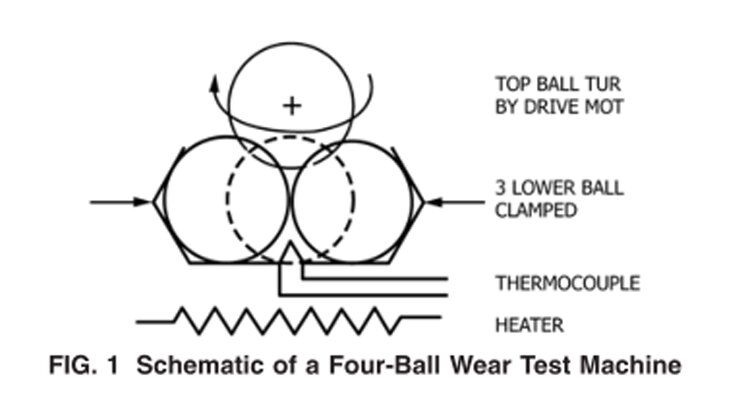

This machine selects different friction vice forms for testing under certain contact pressure in the form of sliding, rolling, and compound friction so as to evaluate the long-time anti-wear performance of lubricating oil and grease, as well as the friction and wear performance of metal materials.

Product Details:

RT-228 Multi-Specimen Test Machine is a sliding, rolling, and composite friction form under a certain contact pressure; choose different forms of friction vice for testing so as to evaluate the long-term anti-wear performance of lubricating oil, grease and friction and wear performance of metal materials. The machine is equipped with three kinds of friction parts, such as four balls, a pin disc, a thrust ring, etc. According to the user’s demand, it can provide as many as seven sets of 10 kinds of friction parts and non-standard customized friction forms, such as ball disc, ball – three pieces, and pin – three columns. The machine can measure the friction torque, calculate the friction coefficient, connect to the computer and record the temperature-time curve and friction coefficient-time curve. It can be equipped with a high-precision measuring device, which can measure the friction vice wear spot size, sense of realization of the friction vice wear spot of the computer screen display, measurement, and recording.

The machine can completely replace the U.S. FALEX-6 type testing machine, and the specimen with the same type of equipment in the United States specimen common, can successfully complete a variety of tests. According to the user demand part of the test function can be customized.

Product Features:

1. Low-speed pin disc (with large and small discs, single pin and three pins) friction function, four-ball long-time anti-wear performance and four-ball rolling contact fatigue, ball a bronze three-piece lubrication performance, as well as thrust washer, ball a disc, mud wear, rubber seals, lip sealing torque and stick-slip friction performance of the test, matched with the reciprocating module can be realized by the reciprocating friction and wear movement.

Standards Compliant

SH/T 0189-92 Method for the determination of anti-wear property of lubricating oil (four-ball method);

SH/T 0204-92 Method for the Determination of Anti-wear Property of Lubricating Oil (Four-ball Method);

SH/T 0762-2005 Method for the determination of coefficient of friction of lubricating oil (four-ball method);

GB/T 12583-1998 Determination of Extreme Pressure Properties of Lubricants (Four-ball Method);

Specification

| ITEM | DESCRIPTION |

| Product Name | Universal Friction Wear Testing Machine |

| Model | RT-228 |

| Maximum test force | 1000N |

| Spindle speed range | 5-2000r/min |

| The maximum value of friction torque | 2.5Nm |

| Relative error of test force indication | ±1% |

| Temperature control range of specimen | room temperature~200℃ |

| Overall dimensions (L×W×H) mm | 860×740×1560 |

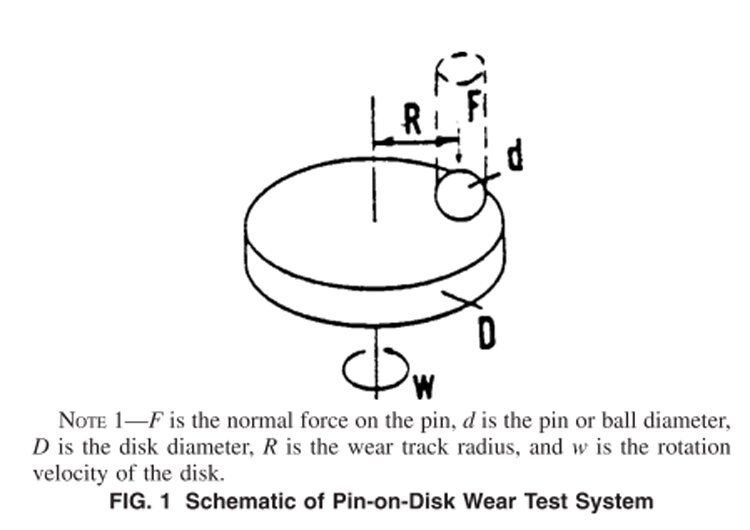

Pin On Disc Wear Test – Working and Basics

Main technical specifications of the Universal Friction Wear Testing Machine

1. Test force

2. Friction torque

3.Spindle pulse width stepless speed range

4.Testing machine heating system

5. The taper of the main axis of the testing machine 1:7

6. Maximum distance between the main axis of the tester and the lower sub-disk >75mm.

7. Test machine spindle control

8. Tester time display and control range 1-9999 seconds/minute

9. Tester speed cycle display and control range 1-999999

10. Maximum output torque of the main motor of the tester 5N-m

11. Net weight of the tester 650Kg

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)