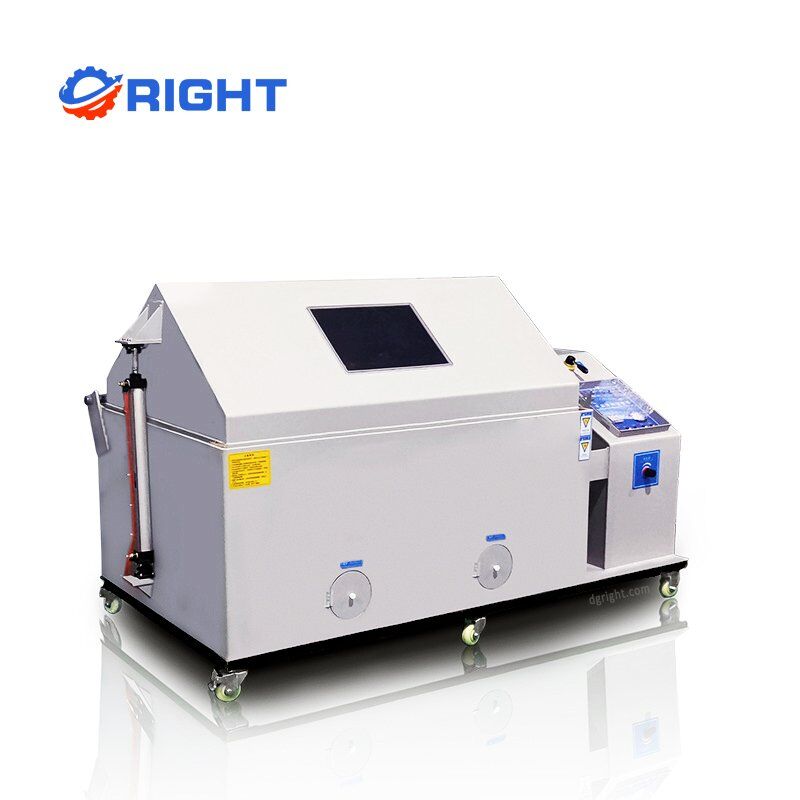

Precision Neutral Acid Cyclic Corrosion Test Chamber (RT-327)

Small Salt Spray Test Chamber Neutral Acid Spray Test Corrosion Test Chamber

The Acid (CASS) Test Chamber is designed to test the corrosion resistance of product surfaces made of various materials after electroplating, anodizing, spraying, anti-rust oil and other anti-corrosion treatments.

Product Details:

RT-723 Acid (CASS) Test Chamber The artificial simulation of a salt spray environment test is a testing equipment with a specific volume space, the salt spray test chamber, which uses manual methods to create a salt spray environment in its volume space to assess the quality of the product’s salt spray corrosion resistance performance. Compared with the natural environment, the chloride salt concentration in its salt spray environment can be several or tens of times higher than the salt spray content in general natural environments, greatly increasing the corrosion rate. The time required to obtain salt spray testing results on products is also greatly shortened. Suppose a product sample is tested under natural exposure conditions. In that case, it may take up to 1 year for it to corrode, while testing under artificial simulated salt spray conditions only takes 24 hours to obtain similar results.

Product Parameters:

| Model | RT-327A | RT-327B | RT-327C |

| Inside box size(cm) | 60x45x40 | 90x60x50 | 120x80x50 |

| Outside box size(cm) | 107x60x118 | 141x88x128 | 190x110x140 |

| Testing room temperature | Salt test (NSS ACSS)35℃±1℃/ Corrosion Test (CASS)50℃±1℃ | ||

| Pressure barrel temperature | Salt test (NSS ACSS)47℃±1℃/ Corrosion Test (CASS)63℃±1℃ | ||

| Brine temperature | 35℃±1℃ 50℃±1℃ | ||

| Testing room capacity | 108L | 270L | 480L |

| Brine tank capacity | 15L | 25L | 40L |

| Salt concentration | The concentration of sodium chloride 5% or the 5% concentration of sodium chloride add 0.26g per liter of copper chloride (CuCl2 2H2O) | ||

| Air pressure | 1.00±0.01kgf/cm2 | ||

| Spray volume | 1.0~2.0ml/80cm2/h (working at least 16 hours, then take the average) | ||

| Testing room relative humidity | 85% above | ||

| PH | 6.5~7.2 3.0~3.2 | ||

| Spray form | Programmable spray (Including continuous and intermittent spray) | ||

| Power | AC220V1Φ10A | AC220V1Φ15A | AC220V1Φ20A |

Product Advantages:

Box Structure

1. The overall molding is welded at high temperatures, corrosion-resistant, easy to clean, and leak-free.

2. The tower spray system is equipped with a salt liquid filtration system, without a crystallization nozzle, the salt spray is evenly distributed, and the sedimentation is freely adjusted.

3. The box cover is made of transparent material to clearly see the test items and spray in the box.

4. A water-sealed structure is used between the box cover and the box body to prevent salt spray from overflowing.

5. The circuit control board and other components are fixed in a position that is easy to inspect and maintain. The door lock opening edge cover door is used, which is not only beautiful but also convenient for maintenance.

The neutral salt spray test is currently the most widely used accelerated corrosion testing method in various fields. It uses 5% sodium chloride saline solution, and the solution PH value is adjusted in the neutral range (6-7) as the solution for spray. The average experimental temperature is set at 35 ℃, and the settling rate of salt spray is required to be between 1-2ml/2000px. h.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

Low Frequency Electromagnetic X Y Z Vibration Test Table (RT-1301)

-

RT-322 Rapid Temperature Change Test Chamber

-

RT-321 SO2 Gas Spray Sulfur Dioxide Test Chamber

-

RT-317 Circulating Water Bath 6 Hole Constant Temperature Water Bath

-

RT-307 Xenon Arc Aging Test Chamber

-

RT-304A Walk-in Constant Temperature and Humidity Test Chamber

-

RT-302 Desktop Constant Temperature and Humidity Test Chamber

-

RT-301 Simulate Environmental Testing Chamber

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)