RT-129C Desktop Mini Plastic Injection Molding Machine Manufacturer

Micro Pneumatic Injection Molding Machine

How much do injection molding machines cost?

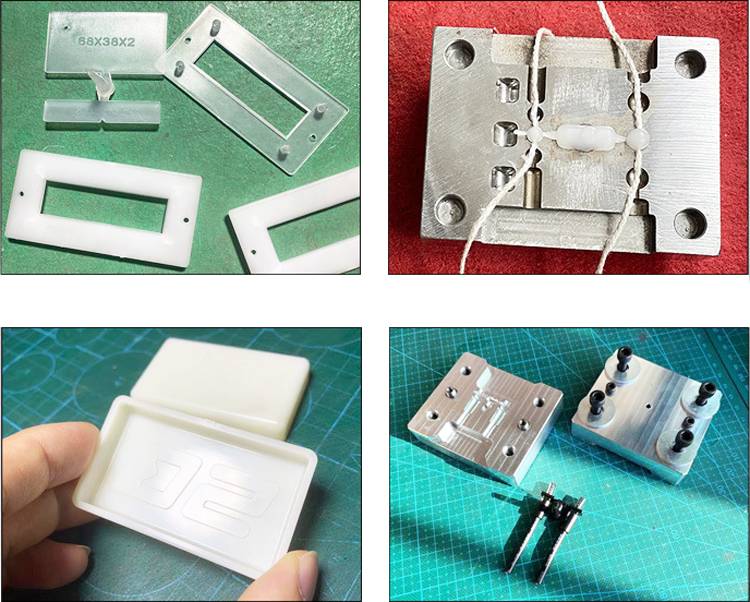

This product is suitable for all kinds of small plastic mold extrusion, small volume, simple operation, low cost, etc. It is the best choice for product research and development, small batch sample production and personal customization.

What are the steps in the injection molding machine process?

Product Details:

Technical Parameter:

Small Batch Production Desktop Vertical Injection Molding Machine

| Model | RT-129C-20 | RT-129C-40 | RT-129C-60 |

| Temperature control range | RT〜450℃(±3℃) | ||

| Plunger diameter (mm) | 25 | 35 | 45 |

| Maximum compressing stroke (mm) | 150 | ||

| Heating cavity size (mm) | 25 * 110 | 35 * 110 | 45 * 110 |

| Maximum injection volume | 20g | 40g | 60g |

| Injection pressure | 1T | ||

| Injection time | 0-9999s (adjustable) | ||

| Cavity structure | Removable cavity can effectively prevent mutual contamination of materials | ||

| Security and protection | Protective door + safety grating (optional) | ||

| Mold mounting maximum size (cm) | 20 * 16 * 21 | 20 * 20 * 21 | 21 * 20 * 21 |

| Machine weight (kg) | 35 | 55 | 65 |

| Power | 800w | 1000w | 1200w |

| Voltage | 220V/ 60HZ | ||

| Air supply | 0.6mpa | ||

| Control way | pneumatic | ||

| Machine size (cm) | 55 * 60 * 130 | 60 * 66 * 140 | 65 * 66 * 155 |

What would you use injection molding for?

This small injection molding machine is very easy to operate. It can be used for short-term production operations, prototype models, and low-cost casting resin molds. It is suitable for a variety of plastic materials, such as PP, PC, ABS, PET, PVC, FRPP/PVC, PPR, EVA, HDPE, MLLDPE, EP…

Features of electric injection molding machine

1、Humanized worktable height design, suitable for large machines, comfortable to operate, thus reducing the operator’s labor intensity and improving work efficiency.

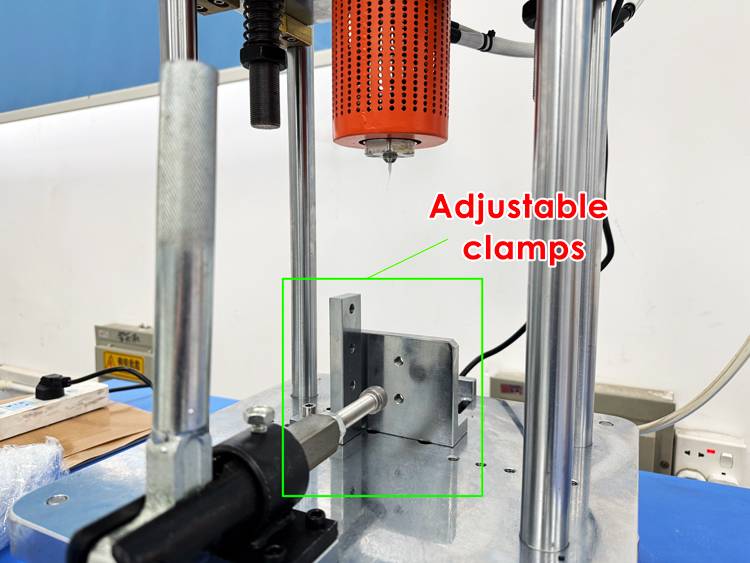

2、The injection molding machine adopts pneumatic operation design, realizing the requirements of fast, simple and easy maintenance.

3、The movable parts of the template and the column are made of high-rigidity copper bushings, realizing the requirements of smooth movement and long service life with high precision.

4、The injection system adopts a pneumatic double-guide column design for smooth movement and high injection precision.

5、Feeding adopts manual feeding.

6、The clamp mold is easy to install and remove, which can significantly improve work efficiency.

7、Adjust the mold-along side control from a convenient, user-friendly angle to facilitate rapid mold exchange.

8、Humanized design shooting table lifting system, convenient, fast, time-saving manpower to adjust or change the mold.

Packing & Delivery

-By plane

-By couriers, TNT, DHL, FEDEX, UPS, etc.

1. Inner Package: Thin plastic film surrounds the machine;

2. Outer Package: Internationally standard package export safety wooden case.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-724 Flame Spread Testing Machine

-

RT-719 Digital Bottles Cap Torque Testing Machine

-

RT-710B Glowing Filament Flammability Tester

-

RT-709 Automatic Sample V Notch Cutting Cutter Machine for Plastic

-

RT-705 Plastic Temperature Deflection Vicat Softening Test Apparatus

-

RT-111 Voltage Breakdown Tester

-

RT-109D Manual Vulcanizing Press Machine

-

RT-701A Plastic MFR Melt Flow Rate Tester

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)