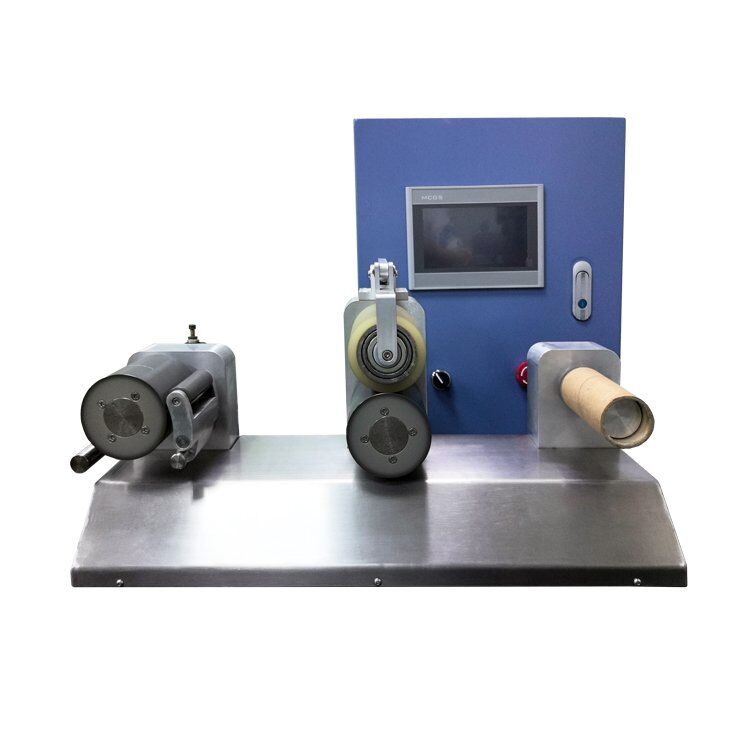

Mini Conical Twin Screw Extruder Machine (RT-739)

Additional information

RT-739 Micro Conical Extruder Desktop Twin Screw Compounder

Control Mode: Constant Speed, Constant Torque

Extruder Design: Conical, Co-/counter rotating

Feeder: Automatic uniform feeding

Application:

- Automotive

- Aerospace

- Electronics

- Polymer Processing

- Polymer Screening

- Colorants

- Specialty inks / Toners

- Building and Construction

- Consumer Products

- Pulp and Paper

Product Details:

Micro Conical Extruder Introduce

Overview

The RT-739 Micro and Lab Compounders offer exceptional value, delivering superior performance and long-lasting durability. Thanks to their robust design—including a durable motor drive, housing, barrel, and screws—these compounders ensure longer lifespans (over 10 years) and reliable, reproducible results over time. With the advanced DGRIGHT technology, you can easily adjust compound volumes (15, 10, or 5 ml), making it incredibly versatile.

These compounders are built for better mixing, allowing for easy control of residence time and offering higher output, thanks to the fully intermeshing screw design. Whether you’re working with injection molding, film production, or (multi) filament extrusion, the RT-739 delivers faster and more consistent in-line shaping compared to any other lab extruder on the market.

Additional features include continuous screw torque monitoring, effortless cleaning (with water cooling and cleaning compound), and no need for specialized screw design knowledge. The RT-739 can also be easily scaled up to larger parallel twin-screw extruders—a capability that sets it apart from the competition. If you only need to melt and extrude materials (such as filaments or films), the RT-739 can operate in continuous mode. It also supports vertical extrusion and can dose fluids without leakage.

In short, the RT-739 Micro and Lab Compounders are perfect for small to medium sample sizes, providing great results that are reproducible, reliable, and fast, with easy scalability for future growth. Ideal for formulation development, feasibility studies, material screening, and resolving technical marketing challenges.

Product Features

Micro-Design: The micro-compounder is designed to handle small batch volumes, with a capacity of up to 15ml. This makes it ideal for research and experimental setups that require precise control over limited sample sizes.

Advanced Configuration: Featuring spiral and pitch-variable screws, the system efficiently prevents high-viscosity polymers from climbing up the screws. Additionally, the recirculation channel is engineered to simulate accurate residence times, ensuring optimal processing conditions.

Versatile Processing: Equipped with advanced rheological control software, the machine allows for the precise measurement of the mixture’s flow properties. Multiple experimental modes are supported, including single-cycle compounding, timed-cycle compounding, continuous feed compounding, constant-speed compounding, and constant-torque compounding, offering flexibility for various testing scenarios.

Ease of Cleaning: The barrel design allows for a full 180° opening, providing easy access for thorough cleaning and maintenance of both the chamber and screws, helping to maintain process hygiene and efficiency.

User-Friendly Operation: With a streamlined process that takes only ten minutes from melting and polymerization to extrusion and injection molding, the system ensures rapid production cycles, making it a practical tool for fast-paced research environments.

Extended Functionality: A range of modular extensions are available, enabling the system to support additional applications such as extrusion, injection molding, film drawing, and spinning, enhancing its utility for diverse processing needs.

Product Specifications

| Product Name | Mini Conical Twin Screw Extruder Machine |

| Model | RT-739 |

| Electric Heating Power | 1600 W / 2600 W |

| Maximum Temperature | 350℃/500℃(specialized for high performance polymers) |

| Volume | 5 g / 10 g / 15 g |

| Cylinder Material | 38CrMOALA |

| Screw Diameter | 5.3mm / 7.4mm |

| Screw Length | 110mm / 154mm |

| Screw Speed | 50~300 rpm |

| Torque Range | 0~5Nm / 0~10Nm |

| Screw Type | Conical Parallel |

| Interface | Touchscreen |

| Circulation Extrusion Raw Material Consumption | 5g/10g/15g/time |

| Machine weight | 30kg |

| Dimensions | 580*360*780mm |

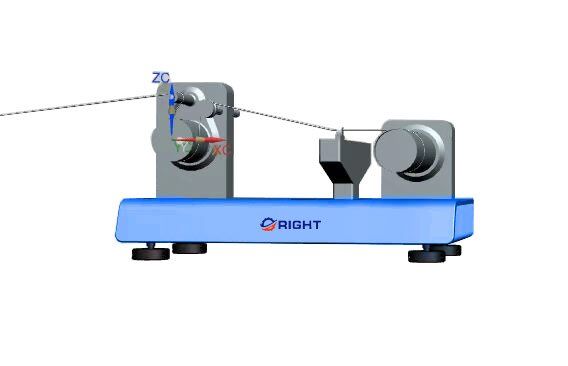

Micro Melt Spinning Machine System

The micro melt spinning machine consists of RT-739 and RT-742 models. Among them, RT-739 is a front-end micro conical twin-screw extruder, mainly used for melting, co-mingling and extrusion of raw materials; RT-742 is a melt spinning machine, which consists of two parts, namely, a silk thread winding device and a silk thread secondary stretching and spinning device. The hardness of the barrel of the melt spinning machine is 64HRC (Rockwell Hardness), and the hardness of the screw is 54HRC (Rockwell Hardness), which is the highest in the industry. The melt spinner can withstand acid and alkali values of PH 0~14 (full range coverage), strong acid and alkali corrosion resistance and super hardness can be late to meet the needs of a variety of polymer research and development; for example, strong acid and alkaline materials, ultra-high viscosity engineering materials, and even can be used for the need to add ceramics or metal powders modified polymer materials. The unique rheological software can be used to monitor the screw torque, shear viscosity, shear rate and shear stress in real time, which can be used to assist in the scaling up of production equipment.

Lab Extruder Micro Blown Film Machine System

Micro Melt Blowing Machine is a laboratory-scale benchtop instrument consisting of RT-739 and RT-740. RT-739 is a front-end desktop conical twin-screw extruder mainly used for melting, co-mingling, and extruding raw materials; RT-740 is a desktop film cast machine consisting of two parts: a film winding device and a film secondary stretching device.

The microfilm extruder machine adopts precision extrusion and high-performance casting molding technology, which is suitable for the casting molding of PE casting film, PP casting film, TPEcasting film, PC casting film, EVA casting film, PVC casting film and composite materials and other common polymer materials, providing laboratory solutions for the preparation of new functional films. It is a precision, high-performance film-forming experimental equipment

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-724 Flame Spread Testing Machine

-

RT-722 Computerized Plastic and Metal Power 10KN, 20 KN Capillary Rheometer

-

RT-710B Glowing Filament Flammability Tester

-

RT-707 Plastic Pipe Drop Hammer Impact Test Machine

-

RT-110D Desktop Small Two Roll Mill

-

RT-109B 10T Plastic and Foaming Rubber Flat Vulcanizing Press Machine

-

RT-701B Plastic Melt Flow Rate Index Tester

-

RT-129 Desktop Manual Plastic Injection Molding Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)