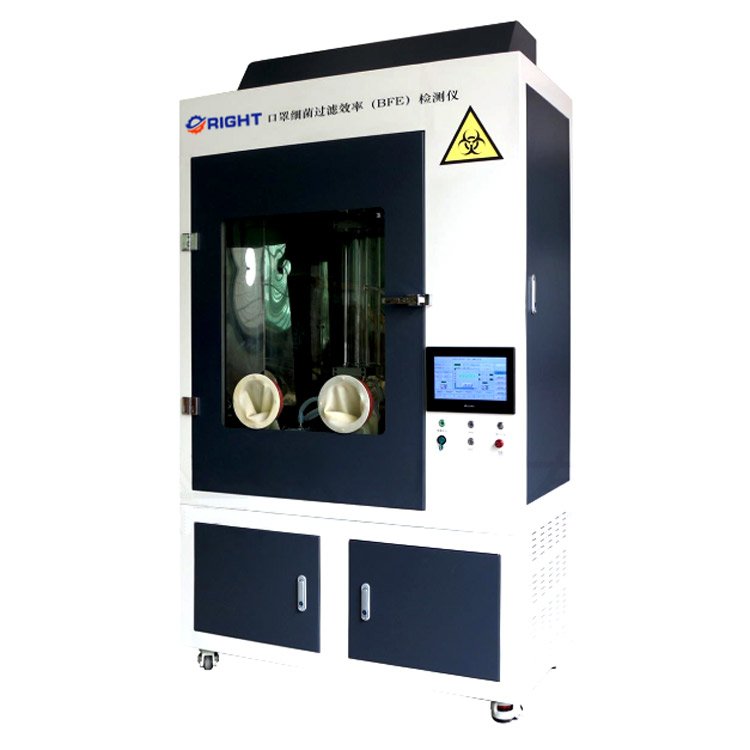

RT-2517 Mask Bacterial Filtration Efficiency BEF Test Equipment

ASTM F 2100 Medical Face Mask Materials Bacterial Filtration Efficiency %(BFE) Tester

Product Details:

Product Description

RT-2517 Mask Bacteria Filtration Efficiency (BFE) tester is mainly used for the measurement of mask bacterial filtration efficiency performance by metrological verification departments, scientific research institutes, medical mask production units and their related testing departments. It is composed of aerosol generating system, aerosol chamber and aerosol transmission device, negative pressure cabinet, 28.3L / min sampler, etc., and the entire detector is controlled by the console. The console uses a microcomputer control system to coordinate and control the work of the aerosol generation system, transmission system, negative pressure cabinet, and sampling system, and displays the working status in real time. The entire measurement work is automatically completed.

Comply Standard

It meets the technical requirements of YY 0469-2011 medical surgical mask. Appendix B. Bacterial Filtration Efficiency (BFE) Test Method B.1.1.1 test instrument requirements, and also meets the requirements of ASTM F 2100, ASTM F 2101, EN 14683 standards.

Product Features

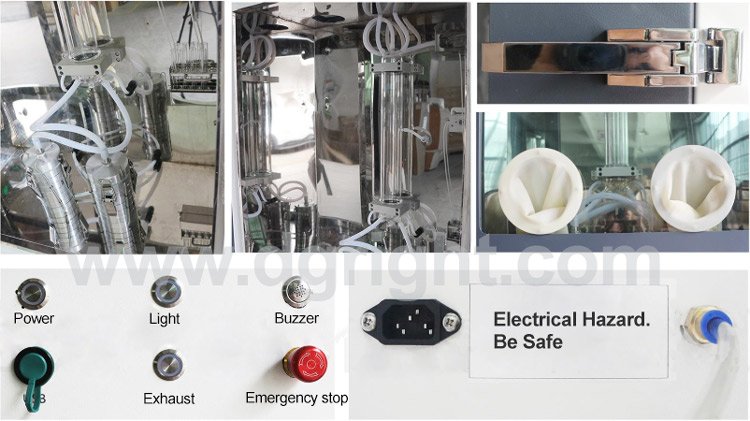

- Negative pressure test system to ensure the safety of operators.

- Built-in peristaltic pump in negative pressure cabinet, A, B two-way six-level Anderson.

- The flow rate of the peristaltic pump can be set according to the situation.

- The flow rate of the bacterial liquid mist of the special microbial aerosol generator can be set, and the atomization effect is good.

- Industrial microcomputer control.

- High-brightness color touch screen.

- USB interface, support U disk data transfer.

- Built-in high-brightness lighting lamp for easy observation.

- Built-in built-in leakage protection switch to protect the safety of operators.

- The front glass door is convenient for the operator to observe and operate.

Technical Parameter

| The main parameters | Parameter range |

| Vacuum pump | Oil-free rotary vane vacuum pump, the maximum flow rate can

reach 57LPM, equipped with a silencer, the air flow is stable. |

| Aerosol generator

flow control |

The flow control of the aerosol generator adopts mass flow control,

with precise control. |

| Channel I sampling flow | Anderson sampling flow rate 28.3L / min, resolution: 0.1L / min |

| Channel II sampling flow | Anderson sampling flow rate 28.3L / min, resolution: 0.1L / min |

| I and II sampling | Equipped with mass flow controller |

| I Pneumatic pressure | 0~5KPa |

| II Pneumatic pressure | 0~5KPa |

| Spray flowmeter pressure | 0~300KPa |

| Aerosol negative pressure | 0~120KPa |

| Operating temperature | 0~50℃ |

| Cabinet negative pressure | 0~120Pa |

| Data storage capacity | Data can be downloaded via U disk |

| Mass flow controller | 0-20L / min, resolution: 0.1 L / min |

| Peristaltic pump flow | (0.01~3.0)mL/min |

| High efficiency air filter characteristics | Filtration efficiency for particles above 0.3um ≥99.99% |

| Aerosol generator mass median diameter | Average particle diameter (3.0 ± 0.3) μm, geometric standard deviation≤1.5 |

| Two-way 6-level Anderson sampler captures particle size | Level Ⅰ>7μm,Level Ⅱ (4.7~7)μm,Level Ⅲ(3.3~4.7)μm,

Level Ⅳ(2.1~3.3)μm,Level Ⅴ(1.1~2.1)μm,Level Ⅵ(0.6~1.1)μm |

| Aerosol chamber specifications | (600×80×5)mm |

| Total number of positive quality control sampler particles | (2200±500)cfu |

| Ventilation flow of negative pressure system | 800m³/min |

| Operating room size | (740×940×440)mm |

| Product size | About 1200×650×2100mm |

| Instrument noise | <65Db(A) |

| weight | 120kg |

| Machine power consumption | <1500W |

The standard configuration

- Host of BFE experiment system

- Level 6 Anderson Sampler

- Aerosol generator

- Glass mixing chamber

- Sampling pump

6. Silicone tube

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-2536 Mask Particle Filtering Effect Test System

-

-300x300.jpg)

RT-2522 Mask Flammability Tester

-

RT-2508 Protective Clothing Synthetic Blood Penetration Tester

-

EN149 Nacl And Oil Type Mask Particle Filtration Efficiency PFE Tester

-

-300x300.jpg)

RT-2502B Mask Respiratory Resistance Tester

-

RT-2528A Automatic Mask Full-field Test System

-

RT-2507 Mask Synthetic Blood Penetration Tester

-

RT-2532 Full Face Mask Air Tightness Test Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)