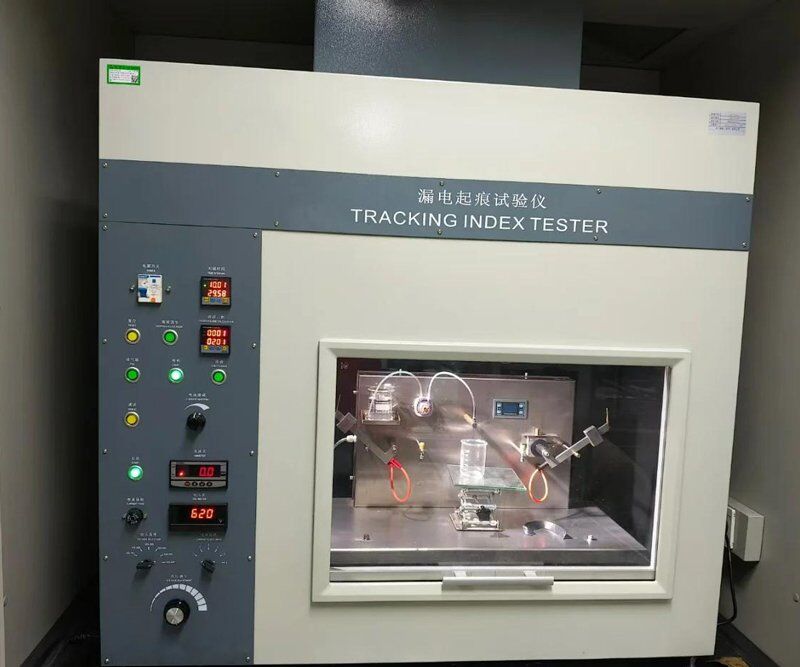

600V Leakage Trace Tester (RT-727A)

Product Details:

RT-727A Electric Trace Resistance Index Tester

Electrical Tracking and Erosion Test (ET&E) is a key testing method for evaluating the ability of insulation materials in electrical products to resist degradation and damage caused by surface leakage current under specific conditions. This experiment simulates harsh environments such as humidity and pollution that may be encountered in actual use to test whether the surface of the material can effectively prevent the formation of leakage channels when subjected to continuous voltage, thereby avoiding short circuits and faults in electrical equipment. This article aims to explore in depth the principles, standards, testing methods, and characteristics of the electrolyte used in the leakage trace test, in order to provide reference for researchers, engineers, and product quality control personnel in related fields.

Working Principle:

Specification

| Product name | IEC 60112 PTI and CTI Tracking Index Test Apparatus |

| Model | RT-727A |

| Application | Determination of relative leakage tracking index and leakage resistance tracking index applicable to insulation materials |

| Testing voltage | 100V~600V (25V division, adjustable) |

| Control mode | PLC programming + touch screen control |

| Drip method | Peristaltic pump or infusion pump is optional |

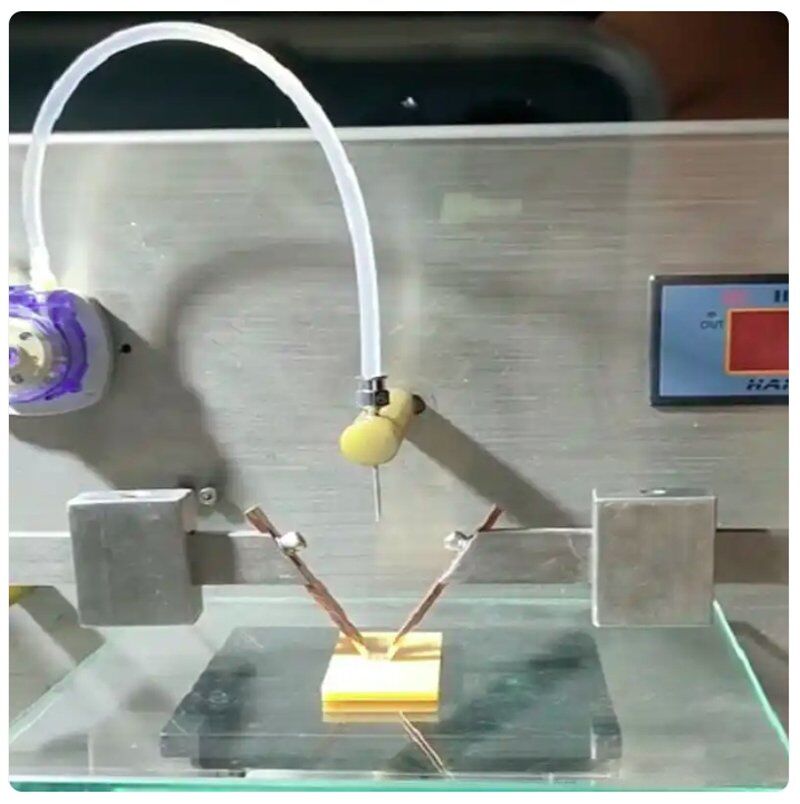

| Electrode material | Test electrode – platinum, electrode rod – copper or brass |

| Electrode size | 2mm*5mm*40mm |

| Electrode distance | 4± 0.01mm |

| Electrode pressure | 1.0N ± 0.05N |

| Test solution resistance | Solution A: 0.1% NH4Cl, 3.95± 0.05Ωm, Solution B: 1.98 ± 0.05Ωm |

| Drop Volume | 20 drops 0.380g~0.480g, 50 drops 0.997g~1.147g (adjustable) |

| Droplet height | 35± 5mm (adjustable) |

| Droplet time | 30s ± 0.1s (adjustable preset), 50 drops time 24.5min ± 2min |

| Number of droplets | 1~9999 (can be set) |

| Test wind speed | 0.2m/s (new standard) |

| Trace judgment | 0.50A±10%,2.00s±10% |

| Power | AC220 (± 10%) V/50HZ (other specifications can be customized) |

| Power supply voltage drop | 8% at 1.0A ± 0.1A |

| Machine size | 1120W*520D*1250H |

| Weight | 75KG |

Operation Steps

1️⃣ Sample placement: Place the qualified samples on the sample table and form a 20 ° angle with the vertical direction. Ensure good contact between the sample and the electrode, without gaps or bubbles.

2️⃣ Adjust electrodes: Adjust the distance between the electrode and the sample based on the thickness and material of the sample. In general, the distance between the electrode and the sample is 4.0mm ± 0.01mm.

3️⃣ Set experimental parameters: According to standard requirements, set parameters such as test voltage, drip time, and drip volume. The general test voltage is 600V, the drip time is 1 minute, and the drip volume is 1 drop per minute.

4️⃣ Start the experiment: After everything is ready, turn on the power switch and start the experiment. Observe the changes in the sample during the testing process. If any abnormal situations occur, the test should be stopped immediately.

5️⃣ After the experiment is completed, turn off the power switch, remove the sample, and clean the test bench and electrodes.

6️⃣ Attention: The electrolytic products generated during the experiment may cause damage to the equipment, and regular maintenance and upkeep of the equipment should be carried out.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

IEC60587 High Voltage Tracking Index Tester 45Hz to 60Hz (RT-727)

-

Wire and Cable Elongation Tester (RT-1308)

-

Cable Life Tester Automatic Plug Wire Swing Bending Testing Machine (RT-1302B)

-

Thermal Radiation Flame Propagation Tester (RT-746)

-

RT-1310 Wire and Cable AC and DC High Voltage Tester

-

RT-1306 Thermal Stability Testing Machine

-

RT-1304 Metal Wire Repeated Bending Testing Machine

-

RT-1303 Heating Deformation Testing Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)