RT-109A Lab Rubber Vulcanizing Press Machine

Additional information

| Capacity | 10,20,30,50,80,100T |

|---|---|

| Temperature range | Normal temperature~300℃ |

| Temperature precision | ±2℃ |

| Temperature controller | LED button type control mode and PLC touch-screen programmed control mode |

| The method of temperature control | LED button type control temperature or PLC touch-screen programmed control temperature |

| The way of heating | Electric heating |

| Heating up time | Normal temperature~160℃ about 20min |

| Timer | LED display or PLC touch-screen displayer |

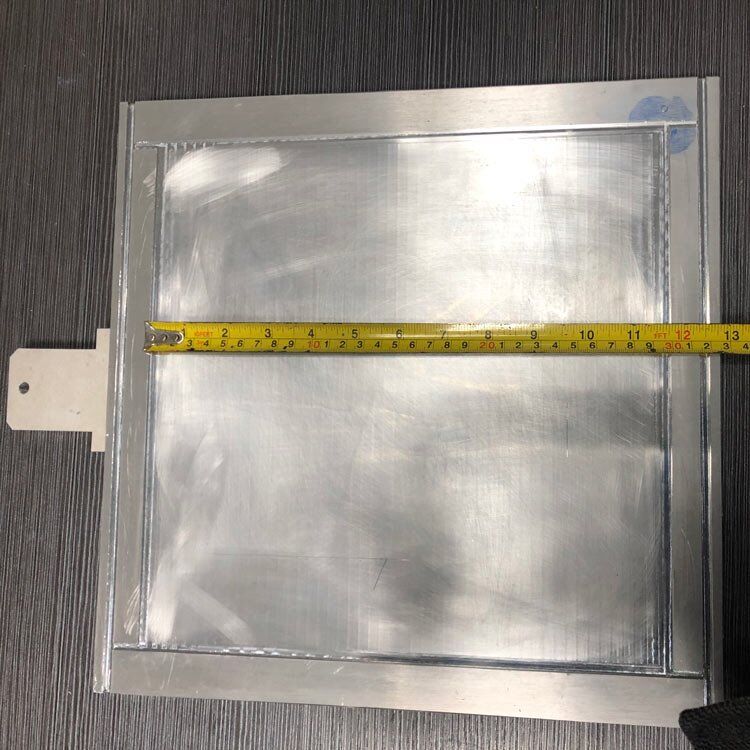

| Heating plate size | 350x350mm,500x500mm,1m*1m |

| The number of heating plate layers | Single-layer |

| The max.distance between up and lower heating plate | 300,500mm,800mm |

| The min. distance between up and lower heating plate | 50mm |

| Exhaust function | Low pressure automatically exhaust 3~10 times per minute (Adjustable) |

| Cylinder stroke | Max 250mm |

| Cylinder speed | 11mm/s |

| Pressure gauge | 0~200kg/sq.cm |

| Dimension | 2*1.5*2.5(m) |

| Weight | 2.5T |

| Motor power | 4KW |

| Pressure | 380V/60HZ(or 50HZ) |

| Machine size | 1200x560x1500(LxDxH mm) |

RT-109A Rubber Vulcanizing Press Machine

This machine is placed in the casting mold and clamped between the electric-heating flat plates to apply pressure and temperature, make the material shaping, testing and serving as the basis for the ingredient of mass production.

Product Details:

Equipment Description:

This series of flat vulcanizing machine is the main equipment that can be used in pressing all kinds of rubber model product and non-model product. In addition, it also can be used in pressing all kinds of thermosetting plastic and foaming rubber and plastic product. With independent actuating unit and electric system, apply button centralized control. Within certain limits, working pressure and heating temperature can be adjusted. This kind of model, can be classified manual operate and semi-automatic operate. The flat vulcanizing machine with the function of a high degree of automation, easy operation,energy conservation and environment protection, and also superior performance.

Main Features:

1.Controlled by PC or manual, performance reliable, high degree of automation. Can automatically identify the wrong command,so avoid the accidence which caused by wrong operation.

2.The preprogrammed process can be locked, the operator can not change without authorization, so that guarantee the quality of pressed product.

3.With the function of timing open mold, automatically exhaust and reinforcing pressure,etc.

4.Optional: Manual operating or Automatic operating mode.

5.Electrical heating pressing machine apply digital display(or pointed type) to control temperature, and control and display the heating plate temperature.

Application:

It mainly used in producing vulcanizing parallel adhesive type, such as conveyor belt,driving belt, and pressing rubber products, foamed plastic,thermosetting plastic(bakelite) and other plastic products. It also suitable for O ring,the key products such as cell phone, keyboard,remote-control,sealing washer such as pressure cooker, electric cooker, mechanical accessories for household, food, health and medical treatment. At the same time,this machine alsocan be used in complex silicone and rubber fittings production and process, such as nipple,medical supplies, health product, artware, toy seal, electroconductive rubber, automotive rubber parts, industrial rubber parts,medical silicone product, sport equipment, all kinds of vessels, multilayer product and so on.

Introduction:

The main function of flat vulcanizing machine is providing the pressure and temperature for vulcanization. The pressure is generated from hydraulic system by hydraulic cylinder, and the temperature provided by heating tube. The control part of flat vulcanizing machine is mainly consist of high and low pump motor on hydraulic station,magnetic valve,vulcanization time,motion instructions and alarm function, etc.

Technical parameter:

| Parameter Capacity | 10T, 20T, 30T, 50T, 80T, 100T |

| Temperature range | Normal temperature~300℃ |

| Temperature precision | ±2℃ |

| Temperature controller | LED button type control mode and PLC touch-screen programmed control mode |

| The method of temperature control | LED button type control temperature or PLC touch-screen programmed control temperature |

| The way of heating | Electric heating |

| Heating up time | Normal temperature~160℃ about 20min |

| Timer | LED display or PLC touch-screen displayer |

| Heating plate size | 350x350mm,500x500mm,1m*1m (or Customized according to customer requirements) |

| The number of heating plate layers | Single-layer(or double/ three layers) |

| The max.distance between up and lower heating plate | 300,500mm,800mm |

| The min.distance between up and lower heating plate | 50mm |

| Exhaust function | Low pressure automatically exhaust 3~10 times per minute (Adjustable) |

| Cylinder stroke | Max 250mm |

| Cylinder speed | 11mm/s |

| Pressure gauge | 0~200kg/sq.cm |

| Dimension | 2*1.5*2.5(m) |

| Weight | 2.5T |

| Motor power | 4KW |

| Pressure | 380V/60HZ(or 50HZ) |

| Machine size | 1200x560x1500(LxDxH mm) |

Requirement of motor and control:

1.The system including two kinds of operating mode:

Automatical and manual.

2.During manual running:

Turn on opening mold, stop opening mold, turn on clamping mold, stop clamping mode by pressing button, to finish the manual control for opening and clamping mold.

3.Automatically operating process showed as below:

Solenoid valve, and others are vulcanizing time,motion instruction and alarms, etc.

4.Action execution instruction:

a)The process of clamping mold is finished by two low pressure(11KW) pumps and a high pressure(18KW) pump, the hydraulic system drives the lower mold to do the upward movement,when the pressure achieve to the low pressure limit(12MPa), the low pressure pump will stop; When achieving high pressure limit, the high pressure pump will stop, and the whole process finished.

b)During holding pressure, due to use check valve in the hydraulic circuit, so no need to the hydraulic pump work, and keep the pressure of hydraulic system, the holding pressure process finished after 10s.

c)The slow pressure process consist of open mold motor(2.2KW), open mold solenoid valve and high pressure pump. When access to slow pressure step, firstly, the open mold motor and open mold solenoid valve will finish decompression. When the pressure achieve to 0 Mpa, the opening mold motor and open mold solenoid valve will be outage,the high pressure pump will power on and clamp force, when achieve high pressure limit, the high pressure pump will stop and repeat three times, then slow pressure process done.

d)After slow pressure process, access into vulcanizing stage. Similar with holding pressure, but due to longer time(30~45min, different material will be different, time adjustable), the pressure will drop, when the pressure lower than pressure limit limit(16Mpa), will ask for turn on high pressure pump to reinforce pressure until the pressure up to high pressure limit.

e)Open mold is finished by open mold motor, open mold solenoid valve. When the lower mold drop to start position( Controlled by open mold in place stroke switch), the open mold done.

5.Vulcanizing temperature is provided by steam, the boiler produce steam, then access to vulcanizing machine uninterruptedly by manual valve.

6.System setting includes total stop button, open mold instruction button, clamp mold instruction button, vulcanization finish alarm button, and the necessary protect device such as short circuit and overload, etc.

Structure and Principle:

The host is composed of main machine,oil pump, control valve, electrical control.

1、The machine unit is composed of upper base, lower base, oil tank, heating plate, cylinder and piston etc. The four column can support 25T tensile force, and slide way for heating plate up and down.

2、Oil pump unit: low pressure gear pump and high pressure piston pump are driven by two motors, separately supply oil to cylinder by one-way valve.

3、Control valve unit is composed of manual drain valve set on hydraulic station and YX-150 electro connecting pressure gauge, controlling heating plate doing the up-down movement.

Operating principle of hydraulic system:

Press turn on button,motor drive gear pump and high pressure gear pump to run( Direction of rotation of pump should be same as direction of arrows,oil filer-gear pump-overflow valve-check valve-at this time, the hydraulic oil from cylinder into oil filer-gear pump-remote relief valve-check valve-Oil cylinder rise rapidly,flow decrease, the pressure of low pressure overflow valve and remote pressure regulating valve system showed by the black needle of electro connecting pressure gauge. The red needle of electro connecting gauge set to keeping pressure 16Mpa, another one green needle set to 13Mpa. When the black needle and red needle overlap, the pressure gauge will give a signal to stop the motor working.Which is called holding pressure.(Noted: Vulcanizing time should be set DSJ-909 in advance), when the holding pressure time come in, will automatically alarm, at the same time,pull back the control valve handle on the hydraulic pressure station, the heating plate drop quickly, that is open mold. So a working process down. Due to there may be happen pressure reduction, the black needly overlap with green needle(that is no holding pressure),at that time, the motor will operate again,making the black needle and red needle overlap, that is automatically pressure.Automatical pressure make not effect on vulcanizing time.

Adjustment for hydraulic pressure system:

1、The adjustment of remote pressure regulating valve: This valve plays a role in adjust working pressure, so setted pressure should be a little bit higher than rated working pressure 15-15.5Mpa, the valve already be adjusted before leaving factory, the customer should not disorderly adjust. If there is any operating accident, the responsibility should be charged by yourself.

The adjustment for electro connecting pressure gauge: adjust red needle to required pressure for holding pressure.(Value: 16Mpa, total pressure of machine is 315 Ton.)

Heating system and flat heating system:

1、Electric heating

This system apply three phase four wire power supply, the machine shell should be grounding,ensure the safety, The inlet wire normally should not smaller than 4-6mm2, and equipped with circuit brake protection. When power on, turn the combination switch Q on the connecting position, and then turn on SB2 button, oil pump motor begin to work, when the flat plate increase,with pressure, until the pressure gauge connective, oil pump motor stop to operate,machine begin to vulcanization, time relay KT1 begin in counting with Unit second. During the operating process, if drop(that is black needle leaves red needle) to green needle position, system will connect to oil pump for pressure, until achieving predetermined pressure. However, you also can pressure by manual(that is press SB2 button), so when drop and you can pressure on time.Automatically pressure will not effect vulcanizing machine time keeper during the operating process. When vulcanization done,there will be alarm for reminding the staff of opening mold. The time of alarm is can be set by KT1, factory setting is 10s, and customers can adjust by themselves, or press SB1 to stop alarm.

(Attention: If there is any abnormal situation, should check the rely of electrical cabinet whether in good condition, or loose, or drop out? When emergency situation happen, press SB1 stop button, the oil pump will stop operating.)

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

Plastic Hot Press Forming and Rubber Vulcanizing Press Machine Manufacturers

-

RT-118 Rubber Trimming Machine

-

RT-112 Rubber Hose Friction Tester

-

RT-108B Rubber Rebound Resilience Impact Tester

-

RT-110A Rubber Two Roll Mill Machine (electrical heating)

-

RT-120B 10L Laboratory Banbury Rubber Internal Mixer

-

RT-115 Pneumatic Rubber Tensile Test Cut Specimen Machine

-

Rubber Moving Die Rheometer MDR Rotorless Curemeter Price (RT-101)

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)