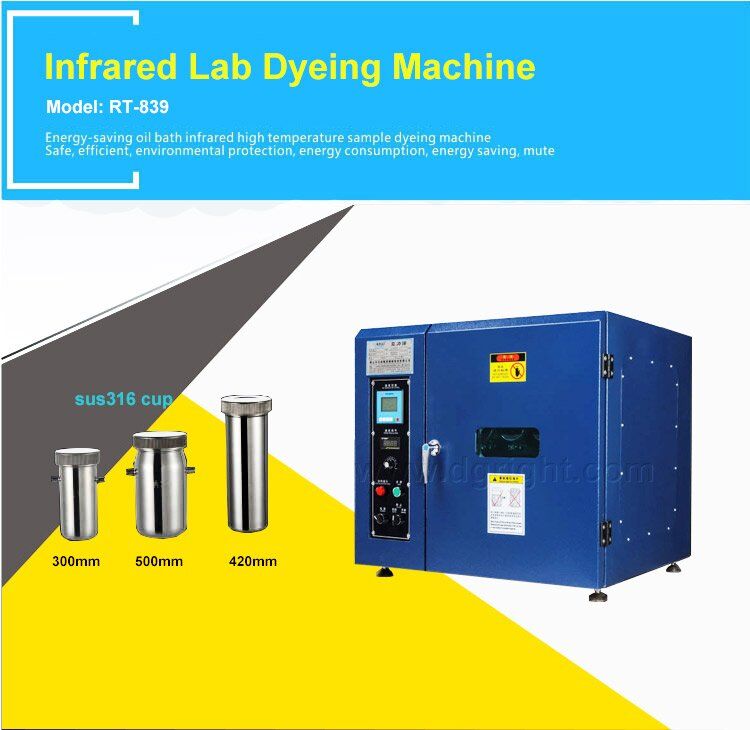

RT-839A High Temperature Lab Infrared Sample Dyeing Machine Manufacturer

IR Lab Dyeing Machine – Textile Testing Equipment

The Lab Dyeing Machine is suitable for dyeing all types of fibers and substrates. The infrared lab dyeing machine produces precise laboratory sample dyeings with consistent and reproducible results. It can accommodate up to 24 positions with a low liquor ratio, making it suitable for dyeing synthetic and natural fibers. The fabric sample dyeing machine is commonly used in laboratory settings.

Product Details:

What is the function of IR dyeing machine?

The RT-839 Textile Infrared High Temperature Sampler consists of a specimen holder that can accommodate thermal oil, with a series of cup sleeves placed diagonally above it, and finally, the dyeing steel cups are inserted diagonally into the sleeves, keeping the cups tumbled at a similar vertical angle as they rotate, to mimic and reproduce the on-site production pattern completely. The infrared lamp does not heat the cups directly but heats the heat-conducting oil, thus avoiding the temperature difference between the cups, and the temperature-control probe only needs to detect the temperature directly. Compared with glycerin coloring machines, energy consumption saves more than 50% of electricity and does not need to consume a huge amount of glycerin cost. Meanwhile, the cooling method adopts convection-forced air cooling to reduce temperature and avoid water waste. Therefore, this machine has the features of safety, high efficiency, environmental protection, energy saving and consumption reduction, which can fully meet the dyeing and color matching experiments of various printing and dyeing factories, segmented temperature sampling test; segmented, even dyeing and penetration test; acidity, alkalinity, temperature, and bath ratio difference on dye absorption rate test; concentration and other tests, and so on. The machine is also highly personalized, and different specifications of dyeing cups can be made according to customers’ demands.

IR Dyeing Machine Characteristics

3. Heating Power Using single-sided nano-coated infrared lamps:

What are the parameters of dyeing machine?

| 1 | Model | RT-839 Infrared Lab Dyeing Machine |

| 2 | Dyeing Pot Numbers | 12, 16, 18, 24 selectable |

| 3 | Dyeing Pot Volume | 250ml, 300ml, 350ml, 450ml,500ml selectable |

| 4 | Temperature Range | RT.~ 140℃ |

| 5 | Max. Heating Rate | 5C/min |

| 6 | Temperature Accuracy | ±0.5 |

| 7 | Keeping Temperature | 0 ~ 99 mins |

| 8 | Liquor Ratio | 1:5 ~ 1:100 |

| 9 | Rotation Speed | 0 ~ 60 rpm |

| 10 | Heating System | Infrared |

| 11 | Cooling System | Air |

| 12 | Power Supply | AC380V, 50HZ (AC220V is optional) |

| 13 | Dimensions | 12-cups(700*750*750mm), 24-cups(800*750*750mm) |

| 14 | Weight | 12-cups(120kg), 24-cups(136kg) |

What are the advantages of our Fabric Sample Infrared Dyeing Machine?

1. Three-dimensional turning, clockwise and anti-clockwise running, makes level dyeing results 2. Available in bath ratios of 1:5-1:30 and 150CC. 300CC. 350CC. 420CC. 450CC. 800CC stainless steel breakers with 12 cups, 24 cups, cup material SUS316L. 3. Adopting frequency converter control, automatic forward and reverse device and adjustable sample bin running speed, better with the site of the movement of the large products process, 360-degree tumbling movement so that the dyeing liquid in the cup back and forth, the color rate is more uniform, suitable for a variety of fabric dyeing, can be obtained flat and uniform sample cloth.

4. Programmable computer system controlls process , can save up to 99 kind of process, LCD displays temperature, time, process No. and temperature curve, imported high-precision PT-100 temperature probe monitoring the actual temperature of dyeing liquor directly , to let heating and cooling automaticlly.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-825B Paper / Fabric Elmendorf Tearing Strength Tester

-

RT-825A 128N 64N Touch Screen Textile Elmendorf Tearing Tester

-

RT-823 Stoll Quartermaster Universal Friction Abrasive Wear Tester

-

RT-822 Raw Cotton Analyzer Testing Machine

-

RT-817 Automatic Fabric Stiffness Tester

-

RT-816 Textile Pinking Blade Manual Fabric Sample Cutting Machine

-

RT-807 Geotechnical Cloth Perspiration Test Oven For Color Fastness Testing

-

RT-804 ASTM D6241 Geotextile CBR Static Bursting Puncture Resistance Testing Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)