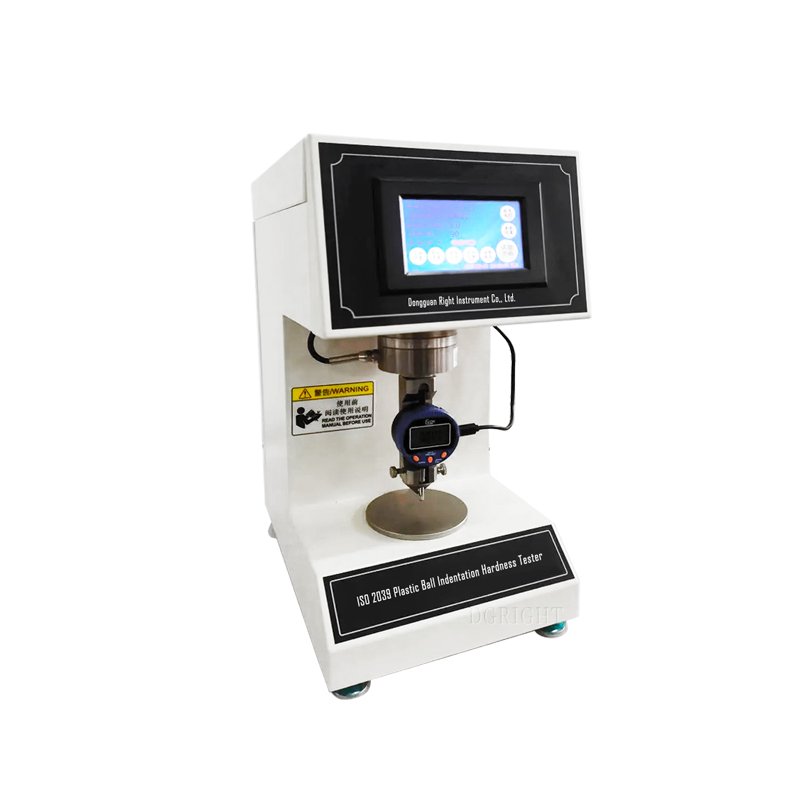

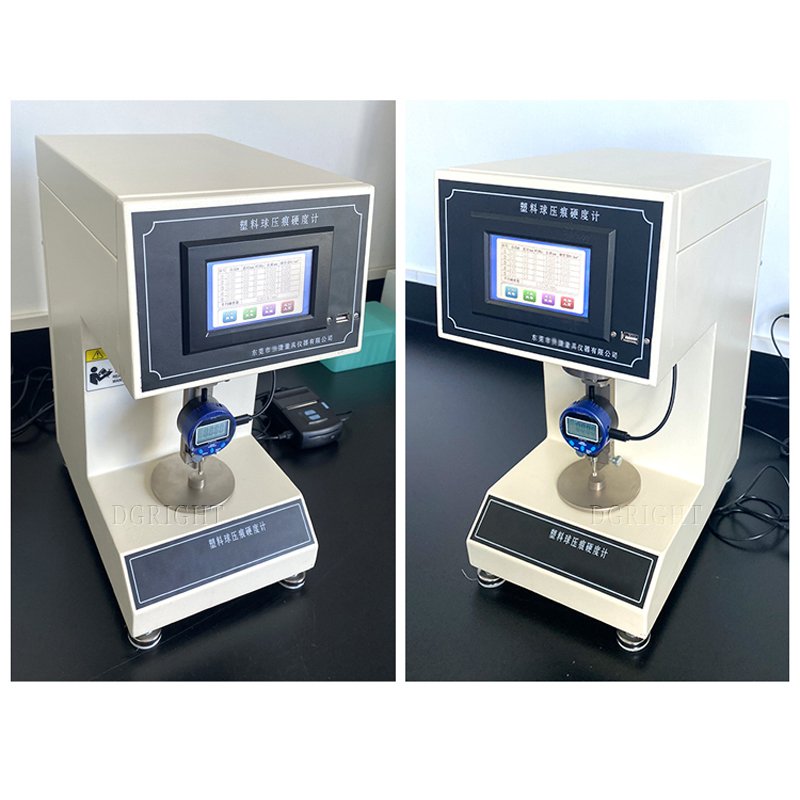

ISO 2039 Plastic Ball Indentation Hardness Tester (RT-1077)

Additional information

Product Details:

Touch Screen Rockwell Hardness Tester for Plastic Ball Indentation Test

The instrument can be used for the determination of automotive engineering plastics, plastic building materials and other industries, material hardness test and can be printed on the data processing, the machine adopts color touch-screen technology, so that the operation is more simple, more intuitive, the picture is more beautiful, this product is my company’s patented products.

Standards Compliant

Product manufacturing and inspection standards:

1. JB/ t741-94 “technical conditions of plastic ball indentation hardness tester”

2. JJG 369 — 1993 “verification rules for the hardness of plastic ball indentation”

Applicable test method standard:

1. GB3398.1-2008 plastic hardness test part I: ball indentation method

2. Iso2039-1:2001 plastic hardness test part I: ball indentation method

Product Paramenters

|

Model

|

RT-1077

|

|

Test load

|

49N, 132N, 358N, 612N, 961N

|

|

Pre-loading

|

9.8N

|

|

Steel ball indenter

|

Φ5mm, Ф10mm

|

|

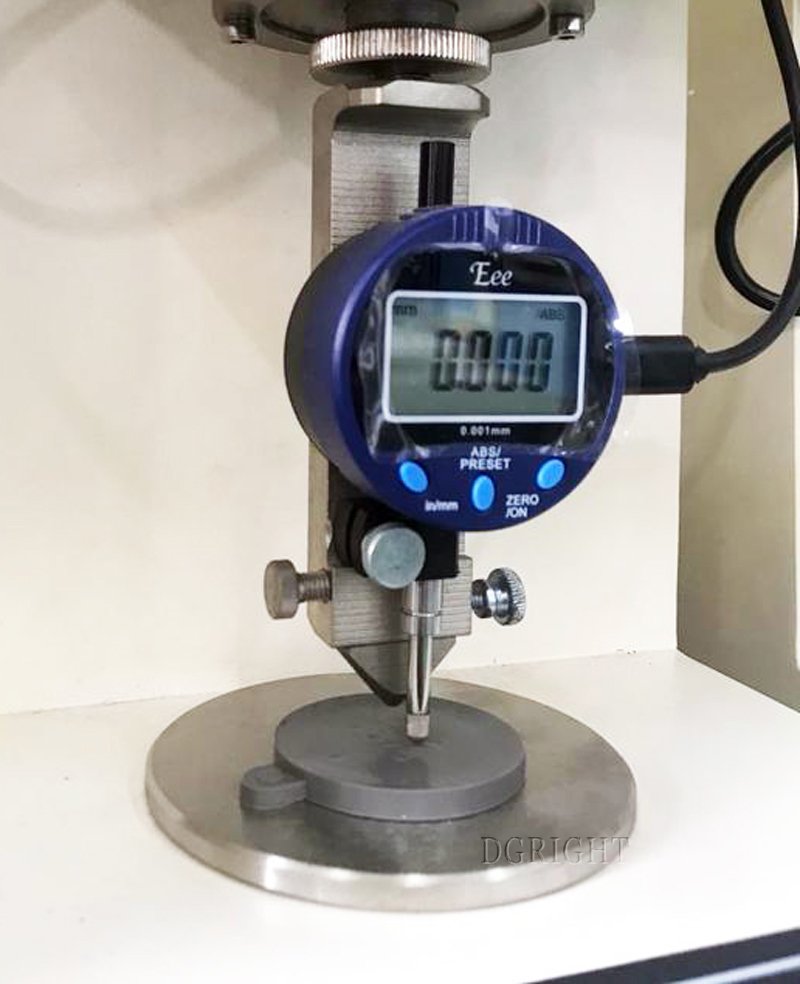

Minimum index value

|

0.001mm

|

|

Maximum height of specimen

|

10mm

|

|

Distance from indenter to machine wall

|

55mm

|

|

Indenter to the base distance

|

25mm

|

|

Demonstrating value accuracy

|

±4%

|

|

Effective measurement range

|

0.150 ~ 0.350mm

|

|

Frame deformation

|

≤ 0.05mm

|

|

Equipment weight

|

45kg

|

|

Equipment size

|

330x220x425 (mm)

|

Product Advantages

1. This instrument adopts microprocessor control and integrated digital measurement and control technology, and is programmed according to the ISO 2039 standard test process.

Accessories

1. Host (1 unit)

2. High precision sensors (1 piece)

3. Deformation sensor 0-6.5mm (1 piece)

4. Pressure head Ф5mm、Ф10mm (each 1 piece)

5. Base (1 piece)

6. Deformation acquisition system (1 set)

7. Load control system (1 set)

Sample Requirements

1. The sample should have uniform thickness, smooth and even surface, no bubbles, no mechanical damage or impurities.

2. The thickness of the sample should not be less than 4mm, and the size of the sample should ensure that the distance between the center of each measurement point and the edge of the sample is not less than 10mm, and the distance between the centers of each measurement point is not less than 10mm. The recommended sample size is 50x50x4mm or 50x4mm in the middle.

Mechanical Structure

Mainly composed of a rack, a pressure head, a loading device, an indentation depth indicator instrument, and an electronic control device.

Precautions

1. During the experiment, it is necessary to ensure that the applied force is perpendicular to the surface of the specimen, and that the supporting surface of the specimen is in good contact with the workbench. The loading during the experiment should be smooth and not subjected to impact or vibration.

2. The installation of the indenter or replacement of the workbench should be tested several times to ensure that the hardness tester is in working condition before conducting the hardness test.

3. The number of trials in each experiment shall not be less than 3 times.

Maintenance of RT-1077 Hardness Tester

1. The hardness tester must be installed in a dry place, with no vibration source, dust or corrosive gases nearby.

2. When using a hardness tester, it must be measured within the specified hardness range. If the hardness range of the tested sample cannot be determined, the load should be gradually increased from small to large.

3. The casing of the hardness tester should be well grounded, and the power should be cut off after use.

4. The hardness tester should be kept clean regularly and covered after use to prevent dust from entering and rust.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-723A TH-9001 Carbon Black Content Tester

-

RT-710B Glowing Filament Flammability Tester

-

RT-708 Hose Hydrostatic Pressure Burst Testing Machine

-

RT-702B Digital Izod Impact Tester

-

RT-129 Small PP PVC Injection Molding Machine

-

RT-109D Manual Vulcanizing Press Machine

-

RT-703C 5J Digital Charpy Impact Tester

-

RT-129 Desktop Manual Plastic Injection Molding Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)