Computer Control Hoses Pulse Pressure Test Equipment (RT-738)

Product Details:

Product Description:

This test equipment is mainly used for the impulse test of hoses and other equipment. As the main equipment for fatigue life under impulse pressure, this test bench plays an important role in ensuring its quality and improving its reliability. It can control the test pressure, test temperature, test number and so on. The test pressure, test temperature, and the number of tests can be controlled. Abnormal conditions can be handled automatically, and the test report can be printed after the test is completed.

The whole control system, we use industrial control computer + secondary control instrumentation system + sensor switch control mode, and all the switching quantities for closed monitoring, and the use of logical relationships to ensure the safety and reliability of the system, to be able to Fault record, automatic system locking logic, to ensure the safety of unattended test.

The box is an organic body composed of a hydraulic system and a heat exchange system, control instruments, and so on. Closed detection switches are installed at the doors for measurement and detection to meet the test safety.

Equipment Features

1. Test medium: water

2. Pulse pressure: 0-32MPa (wave adjustment range 10%-100%)

3. Pulse frequency: 60+/-5 cycles per minute (adjustable) Pulse single discharge volume 200ml

4. Pulse pressure waveform: basic square wave (square wave, trapezoidal wave), pulse width adjustment can be carried out according to the requirements of your organization.

5. Test medium temperature: room temperature (according to customer requirements)

6. Ambient temperature: room temperature (according to customer requirements)

7. Tested parts can be tested 1 way at a time (according to the customer’s requirements).

8. Advanced technology and a reasonable structural design. The appearance is beautiful and has generous characteristics.

9, all the pressure parts are used in the internationally well-known standard parts, without any welding connection, easy to disassemble, with a high safety system, long life, and easy to maintain.

High number, long life, easy to maintain.

10, Computer control of the pressure rate, real-time display of the pressure curve, test reports can be printed after the completion of the test.

11. Adopting servo control technology, it can precisely control the pressure.

12, can be a variety of abnormal conditions, including temperature, pressure, electricity and other abnormalities.

14, Dismantle the leakage medium after being the pipeline automatic recovery;

15, Computer data acquisition and processing, print out the ambient temperature, pulse number and pulse pressure waveform;

16, the test can be freely set the number of running cycle requirements, when the requirements can be automatically stopped when the test;

17, the test can be observed outside the specimen test situation, the observation window is equipped with a protective device;

18, test pressure-time curve can be displayed on the screen and can be printed or stored in the memory, computer control.

The memory has USB interface and can print the experimental pressure curve;

19, for small workpiece test box contains the following safety devices:

a. Door open can not be tested; there is a net line to strengthen the safety glass, emergency button;

b. Media box design with a liquid level alarm, liquid level reaches the lower limit, the whole machine can not start;

c. With oil temperature is super high, pressure is super high, leakage sound and light alarm, emergency stop function;

d. Specimen leakage can be set alarm point. When the leakage reaches a certain level, the system will automatically alarm and stop working.

The system will automatically alarm and stop working when the leakage reaches a certain level;

20, the test system has a pressure sensor calibration interface;

21, support power failure automatically save data;

22. The experimental data can be accessed, and the experimental results can be queried according to the experimental time and the number of experiments.

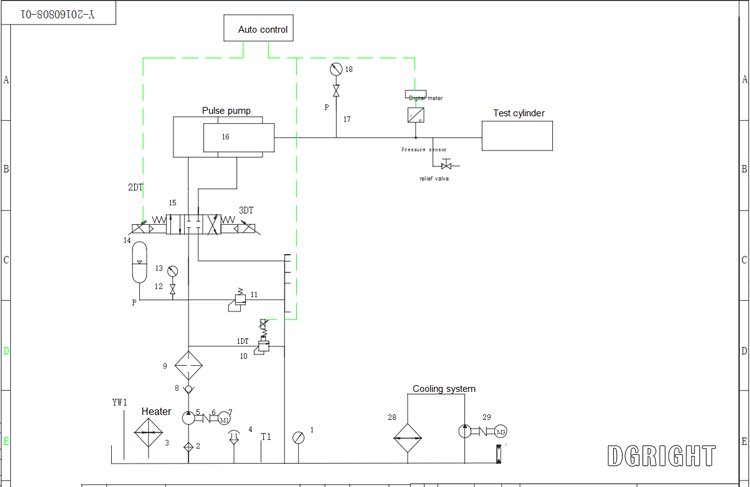

System Composition

Pulse generation device: pulse pump, liquid injection pump, regulator, hydraulic station, proportional valve, piping. Data acquisition control device: computer, acquisition software, pressure sensor, data acquisition card.

Software exception handling device: including pressure, data acquisition.

As shown in the figure: mainly including tanks, power stations, pulse pumps, sensors, high-pressure relief valve, piping and other components.

Among them, the green line is the computer control signal, controlling the pulse start and stop and dealing with abnormal situations, collecting digital display pressure

The green line is the computer control signal to control the pulse start and stop and deal with abnormal conditions, collect the pressure value of digital display and control the automatic pressure relief valve.

The red part is the hydraulic station part, used for pulse pump power, configured with accumulator, air cooler.

The pressure relief valve is divided into two ways of automatic pressure relief valve. At the beginning of the experiment need to exclude the pipeline to be measured parts of the air with.

The upper computer control software integrated control, data acquisition, integrated control to fully meet the requirements.

Pressure control experiment process

At the beginning of the need to open the automatic pressure relief valve, low-pressure pump work, when the automatic pressure relief valve after the liquid out, proving that the air in the pipeline has been discharged, the software set the experimental pressure, experimental time, control of the oil temperature and the ambient temperature, at this time to start the work of the pulse pump, when the software to collect the pressure to reach the set value, the software will automatically control the pulse pump to reciprocate the work of the experimental pressure of the pulse occurs, the pressure of the experiments through the oil pressure proportional valve to realize the control. The experimental pressure is realized through the oil pressure proportional valve to control. The experimental process is automatically recorded in the process of the experiment, and the pressure curve is displayed in real time.

The experimental process is automatically recorded and the pressure curve is displayed in real time. And can realize the playback of the test process.

Technical Parameter

| Test medium | water |

| Test pressure | 0-32MPa |

| Environmental temperature | Room temperature |

| Time display | PC display |

| Pressure curve display | Real-time display by data acquisition software |

| Print report | Test report can be printed and saved after the test is completed Test data |

| Test data saving | Reports and test procedure records can be saved |

| Display Accuracy | 0.01MPa |

| Control accuracy | 2% |

| Test medium temperature | Room temperature |

Test process steps:

1. Connect the measured parts.

2. Adjust the internal oil injection temperature.

3. Inject high-temperature hydraulic oil into the tested part, and exclude air.

4. Close the pressure relief valve, start the software, adjust the pressure of the hydraulic station, holding time, pressure rise time, high pressure time, pressure relief time, the number of experiments.

High-pressure time, pressure relief time, and the number of experiments.

5. Adjust the pressure to start the experiment.

6. During the process, if the measured parts appear abnormal, the process is stopped.

7. Pressure relief after the experiment is completed.

8. Remove the pressure and take out the measured parts.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-724 Flame Spread Testing Machine

-

RT-723A TH-9001 Carbon Black Content Tester

-

RT-708 Hose Hydrostatic Pressure Burst Testing Machine

-

RT-129B Pneumatic Mini Table Plastic Injection Molding Machine

-

RT-129 Small PP PVC Injection Molding Machine

-

RT-109D Manual Vulcanizing Press Machine

-

RT-109B 10T Plastic and Foaming Rubber Flat Vulcanizing Press Machine

-

RT-701A Plastic MFR Melt Flow Rate Tester

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)