IEC60587 High Voltage Tracking Index Tester 45Hz to 60Hz (RT-727)

RT-727 High Voltage Tracking Tester

The RT-727 high-voltage tracking tester is suitable for anti-tracking and erosion testing of electronic products, household appliances, and other materials. It simulates frequencies (45 Hz- 65 Hz) or corresponding DC voltages, liquid pollutants, and slope samples through resistance tracking and erosion measurement to evaluate the resistance of electrical insulation materials to tracking and erosion under harsh environmental conditions.

Product Details:

Working Principle:

Specification

| Product name | High Voltage Leakage Tracking Tester |

| Model | RT-727 |

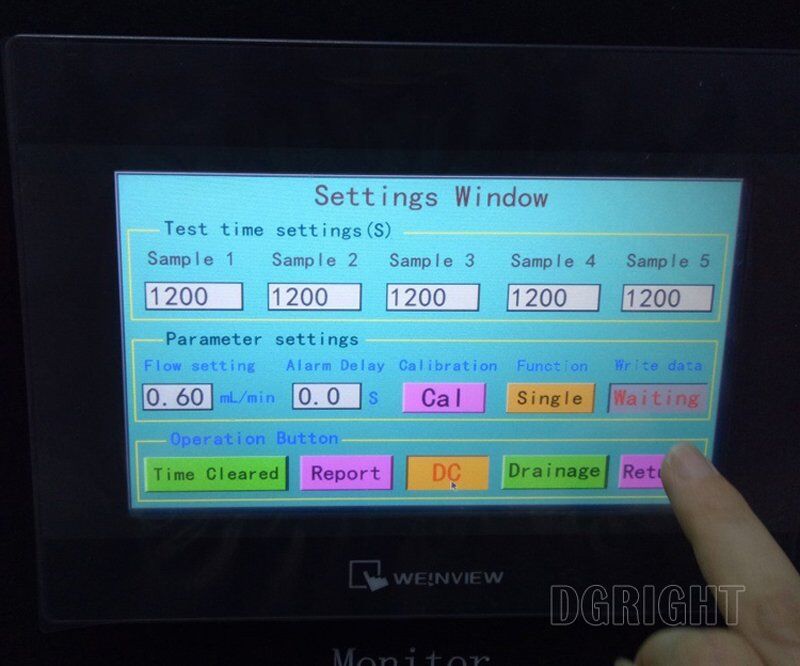

| Control mode | PLC Intelligent Control: Digital Flow Control System, Accurately Control the Flow of Pollutant Liquid, Fully automatic adjustment of precise test voltage. |

| Data output | At the end of the test, automatically determine whether it is qualified or unqualified, generate and print a test report |

| Test voltage | 0- 6000V ± 5% adjustable |

| Polluted liquid | resistivity of 3.95 ± 0.05 Ω· m |

| Pollutant liquid flow rate | adjustable from 0-1.2ml/min |

| Test station | 5 samples are tested simultaneously |

| Electrode | The thickness of the upper and lower electrodes is 0.5 mm, made of 316 stainless steel material, and the size is determined according to standard size requirements. The spacing between the upper and lower electrodes is 50 ± 0.5mm |

| Traceability judgment | If the current reaches or exceeds 60mA and there is a continuous delay of 2.00s (± 10%), stop working and output the result (qualified or not) |

| Power | AC220 (± 10%) V/50HZ (other specifications can be customized) |

| Machine size | Width 1120mm, Depth 520mm, Height 1350mm, Exhaust Aperture Φ 100mm |

| Weight | 85KG |

Product Advantages

What are the advantages of RT-727 High Voltage Tracking Tester?

1. Easy to operate. The test can be automatically conducted by presetting voltage, time, flow rate, and protective resistance.

2. The pollution liquid supply system adopts a pulse pump with high control accuracy.

3. The machine is equipped with exhaust holes and fans to eliminate harmful and corrosive gases generated by discharge to the maximum extent possible, ensuring the health of operators and the safety of equipment.

4. The entire machine is controlled by a PLC+human-machine interface system, and key electronic components are all imported brands.

5. The equipment is equipped with safety protection devices such as power overload, circuit breaker protection, and control circuit overload protection.

6. The work area is equipped with doors with glass windows for easy observation of the experimental process at any time.

Operation Steps

RT-727 Operation Instructions

Firstly, select the sample that meets the test requirements and perform any necessary pre-treatment steps, such as cleaning and drying. Then, place the sample in the test chamber and set the appropriate parameters, such as temperature, humidity, and electric field strength, to initiate the accelerated aging test. During the experiment, it is necessary to regularly observe and record changes in the sample, such as surface tracking, corrosion, and color changes. When there is an obvious electric trace or corrosion on the sample, it is necessary to stop the test promptly and further analyze and evaluate the sample. The advantage of the IEC 60587 test method lies in its standardization and repeatability, which enable the objective evaluation of the resistance to electrical traces and corrosion of different insulation materials, providing an essential basis for the selection and design of electrical equipment. Meanwhile, this method can also simulate the environmental conditions during actual use, making the evaluation results more closely reflect the actual situation.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

600V Leakage Trace Tester (RT-727A)

-

Wire and Cable Elongation Tester (RT-1308)

-

Cable Life Tester Automatic Plug Wire Swing Bending Testing Machine (RT-1302B)

-

Thermal Radiation Flame Propagation Tester (RT-746)

-

RT-1310 Wire and Cable AC and DC High Voltage Tester

-

RT-1306 Thermal Stability Testing Machine

-

RT-1304 Metal Wire Repeated Bending Testing Machine

-

RT-1303 Heating Deformation Testing Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)