EN ISO 11925 Direct Impingement Building Material Flammability Tester (RT-729)

Testing Principles

This experiment determines the combustibility of a specimen in the vertical direction when it encounters a small flame at the edge or surface of the specimen. Observe the combustion behavior of the sample to determine if the flame spreads and if any burning particles or droplets are present.

Product Details:

This product is mainly used for testing the combustion performance of external wall insulation systems and building materials, and as a testing instrument to determine whether building materials are combustible. Production enterprises, relevant quality inspection departments and units, universities, and research institutes are used for heat-resistant and insulation materials.

Standards compliant

ISO 11925-2:2020 EN Reaction to fire tests — Ignitability of products subjected to direct impingement of flame — Part 2: Single-flame source test;

Product Parameters

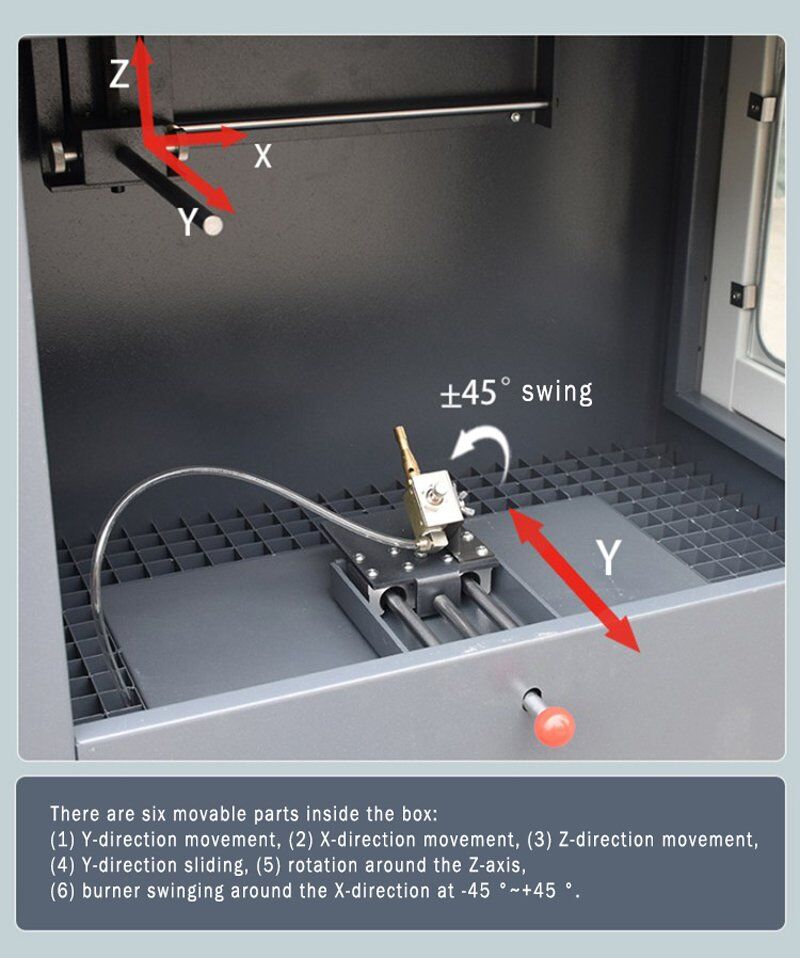

| Movable direction | (1) Y-direction movement (2) X-direction movement (3) Z-direction movement (4) Y-direction sliding (5) rotation around the Z axis (6) burner swinging around the X direction -450~+450. |

| Nozzle aperture | ¢ 0.17mm |

| Flame height | (20 ± 1) mm |

| Igniter timing | 15s, 30s |

| Gas | Propane gas with a purity of over 95% |

| Sample size | 250mm × 90mm, 250mm × 180mm |

| Test sample thickness | ≤ 60mm |

| Environmental temperature | (23 ± 5) ℃ |

| Relative humidity | (50 ± 20)% RH |

| Power supply | AC220V ± 10% 50HZ |

| Machine size | 900 × 400 × 910mm |

| Test box material | stainless steel |

| Clamp | two U-shaped stainless steel frames, with a thickness of 5.0mm |

| Burner | 45-degree angle to horizontal |

| Flue air velocity | 0.7m/s |

| Anemometer accuracy | ± 0.1m/s |

| Flame release time | 0 ~ 99 minutes and 99 seconds can be set |

| Hold time | 0 ~ 99 minutes and 99 seconds can be set |

| Ignition system | high voltage electronic ignition, automatic ignition, reset |

Product Advantages

Test sample

The sample should represent the final use of the product as much as possible. This is particularly applicable to the use of standard substrates as described in EN 13238. Basic flat specimens should be used: Size: 250mm x 90mm, Thickness: up to 40mm (including substrate used during use). Product standards for specific products (groups) may include provisions for sample structure to achieve maximum application range. Can guide more product samples. After confirming the order in writing and debugging the samples according to the standards, testing can begin.

Additional testing of multi-layer specimens

For multi-layer specimens with a thickness greater than 10 millimeters, only single-layer specimens with a thickness greater than 3 millimeters (excluding adhesive layers) require additional flame impact testing.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-712B Automatic Limited Oxygen Index Tester

-

RT-710B Glowing Filament Flammability Tester

-

RT-709 Automatic Sample V Notch Cutting Cutter Machine for Plastic

-

RT-129B Pneumatic Mini Table Plastic Injection Molding Machine

-

RT-111 Voltage Breakdown Tester

-

RT-109B 10T Plastic and Foaming Rubber Flat Vulcanizing Press Machine

-

RT-701A Plastic MFR Melt Flow Rate Tester

-

RT-129 Desktop Manual Plastic Injection Molding Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)