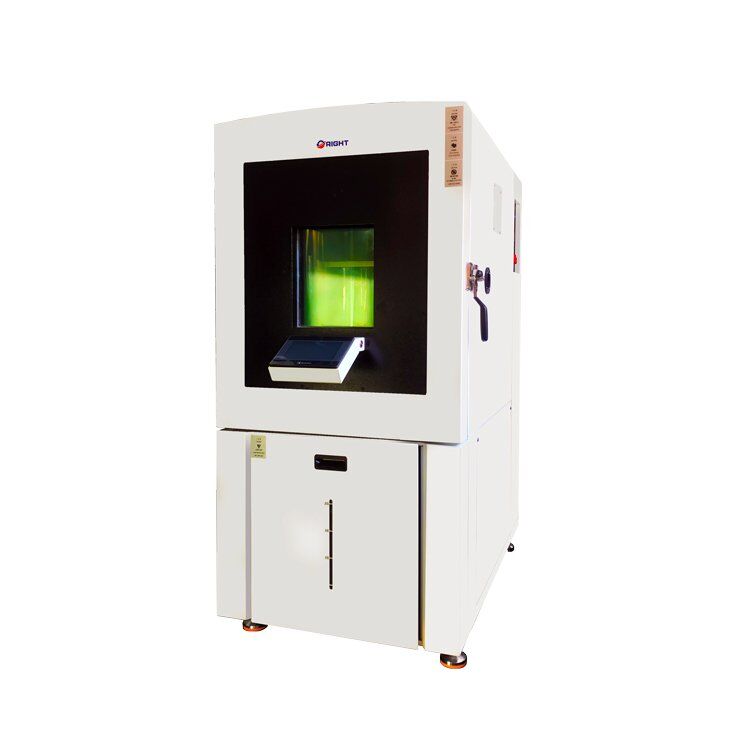

RT-301 Touch Screen Constant Temperature and Humidity Stability Environmental Test Chamber

-70 to 150 Constant Temperature Humidity Test Chamber (RT-301)

The RIGHT company produces automatic constant temperature and humidity test chambers to customer satisfaction for product quality and durability to accumulate many years of rich experience in manufacturing, extensive absorption of user comments, after many technical improvements of excellent products, the choice of components of high reliability, good quality, can guarantee the reliability of various products testing, stability, and accuracy, so users can rest assured that use.

Product Details:

Product Parameters:

| Model | RT-301-80 | RT-301-150 | RT-301-225 | RT-301-408 | RT-301-800 | RT-301-1000 |

| Chamber WxDxH (cm) | 40x40x50 | 50x50x60 | 60x50x75 | 80x60x85 | 100x80x100 | 100x100x100 |

| Temperature range | -70℃~+100℃(150℃) (A:+25℃, B:0℃ , C:-20℃, D:-40℃, E:-50℃, F:-60℃, G:-70℃) | |||||

| Humidity range | 20%~98%R.H.(10%-98%R.H/5%~98%R.H is the specific condition) | |||||

| Accuracy/uniformly | ±0.1℃;±0.1%R.H./ ±1.0℃;±3.0%R.H. | |||||

| Accuracy/volatility | ±1.0℃;±2.0%R.H./ ±0.5℃;±2.0%R.H. | |||||

| Heating/cooling time | About 4.0℃/min;about 1.0℃/min(5~10℃/mm is the specific condition) | |||||

| Inside material | Stainless steel SUS 304# | |||||

| Insulation material | High-temperature, high-density amino acid ethyl ester foam insulation materials | |||||

| Cooling system | Air-cooled/ single-stage compressor(-20℃) ,wind, water cooled/two-stage compressor(-40℃~-70℃) | |||||

| Protection | Compressor overload switches, high and low-pressure protection switches, over-humidity-temperature protection switches, fuses, warning system | |||||

| Accessories | recorder(purchase), view window,50mm testing hole, PL lamp, clapboard, Dry and wet gauze ball | |||||

| Controller | TEMI300 digital controller from South Korea | |||||

| Compressor | France “Taikang” | |||||

| Power | 1Φ 220VAC±10% 50/60Hz & 3Φ 380VAC±10% 50/60Hz | |||||

| Machine size WxDxH (cm) | 58x108x138 | 68x118x148 | 78x118x161 | 98x128x173 | 118x149x188 | 118x169x188 |

Applicable Industries:

Applied to test the product’s quality, such as electronic, plastic products, electrical appliances, instruments, food, vehicles, metals, chemicals, building materials, aerospace, medical care … and so on.

Corresponding Standard:

Product Advantages

Advantage 1: Wind Field Design

Air supply mode: horizontal air supply, which is conducive to the uniformity of the wind distribution around each product when placing multiple products.

Wind direction adjustment: The air outlet is installed with double-layered louvers, which can adjust the wind direction up and down, left and right.

Wind speed/wind volume adjustment: configuration of Dexi inverter, according to the different test requirements of customers to adjust the operation frequency of the circulating motor, to adjust the wind speed/wind volume in the box.

Wind field simulation: SOLIDWORKS three-dimensional mapping and modeling, and the model built ANSYS analysis software to analyze the wind field and temperature distribution and other parameters.

Advantage 2: Refrigeration Energy-saving Technology

Refrigeration system frequency control technology: In the frequency conversion refrigeration system, even if the power supply frequency 50HZ is fixed, the frequency can be changed through the frequency converter so as to adjust the compressor speed, so that the cooling capacity is continuously changed to ensure that the compressor operating load matches the actual load in the test chamber (i.e., the temperature inside the test chamber rises, the compressor frequency rises, increasing the cooling capacity, and vice versa, the compressor frequency decreases, reducing the cooling capacity), which greatly saves the operating unnecessary loss, to achieve the purpose of energy saving. The test chamber at the beginning of the operation of the compressor can also be improved by increasing the operating frequency of the compressor, improving the capacity of the refrigeration system to achieve the purpose of rapid cooling test chamber using frequency conversion refrigeration system, can accurately control the temperature inside the box, so that the temperature inside the box constant temperature fluctuations, but also to ensure that the refrigeration system suction and discharge pressure is stable, the compressor is more stable and reliable operation.

Advantage 3: Intelligent Control System

The inverter controller system mainly adjusts the compressor capacity according to the actual load size to ensure that the total output capacity of the compressor matches the actual load. The control principle is as follows. According to the temperature and suction superheat to be achieved by the box to determine the compressor suction temperature, query the suction pressure value corresponding to the temperature of the refrigerant, set the corresponding suction pressure change range value through the operation panel, after setting, the controller will give a signal (from the suction pressure sensor) according to the change of suction pressure, automatically control the input frequency of the compressor, so as to change the rotational speed and realize Automatic stepless adjustment of the cooling capacity, to ensure that the refrigeration unit operating capacity with the actual load required by the box, to achieve no waste, to minimize the cost of running the refrigeration unit. The role of the electronic expansion valve control system is mainly through the adjustment of the electronic expansion valve opening degree to control the evaporator superheat, to ensure that the actual load in the box and the system to provide a balance of cold, can accurately control the temperature in the box, and make full use of the evaporator.

Configuration and Function of Software:

| Wind circulative system | 1. Using multi-wing centrifugal Rewind fans, strengthen the axis made of aluminum alloy in order to attain loop-forced convection. |

| 2. Stainless steel added long axis. | |

| 3. Stainless Steel Multi-blade centrifugal wind wheel. | |

| Water Supply system | 1. with a water tank at the back |

| 2. automatically supply water | |

| 3. warning for the shortage of water | |

| Cooling system (Diego-style, single machine, refrigerator) | 1. Compressor: France “Taikang” Hermetic Refrigeration Compressor TFHK2522K two-unit |

| 2. Refrigerator: Air-cool condenser coil | |

| 3. Evaporator: pomfret Chip Multi-Segment | |

| 4. Other Accessories: Imported desiccant cooling, Freon-borne window, the U.S. oil-water separator | |

| 5. Expansion System: Italian expansion valve | |

| Temperature and humidity control system | 1.Control Specifications: Original South Korea TEMI880 color LCD touch screen in English and Chinese Accuracy: ±0.5 ℃±1% R.H, Resolution: 0.1 ℃ 1% R.H |

| 2. Functions can accommodate the memory 999 program, optional single-stage control, or multi-segment program control, operating as a functional form model, can be directly programmed, and a solid curve of function and the RS-232 communication interface. | |

| 3. connect with the computer, directly monitored by the computer to operate the program; it also records temperature data and prints! (Need another purchase) | |

| 4. The main components of the system are equipped with safe inspection and interface devices; when an fault occurs, immediately through the LCD displays fault status and cuts off the power | |

| 5. With the cumulative operating time, display the run time | |

| 6. Sensor: PT100 Sensor | |

| 7. Temperature and humidity control diagram attached | |

| Standard Accessories | 1. two groups of adjustable shelf board made of stainless steel; the distance can be arbitrarily changed |

| 2. Perspective vacuum glass windows, explosion-proof type | |

| 3. Wide-angle lighting, using energy-saving high-efficiency fluorescent lights | |

| 4. The machine is equipped with 4 group adjustable fixed wheel axle and control indicator light | |

| 5. a pair of Φ50mm holes for testing | |

| Power | Three-phase 380V ± 10% Power frequency: 50Hz ± 2% 4KW |

| Information and services | 1. To provide equipment drawings, electrical schematics, electrical wiring diagrams, consumable parts, operating manuals, and other technical information, copy of two, and to provide essential technical information. |

| 2. Trained how to operate and maintain the equipment so the staff grasp the skill of the equipment. | |

| 3. Equipment, one year warranty for free maintenance service: after one year, provide the accessories for paying costs price. |

Why Choose Us

Recommend Products

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

ASTM D5423 Air Ventilation Aging Climatic Test Chamber (RT-326)

-

RT-307A Xenon Lamp Aging Tester Manufacturer

-

RT-318 Laboratory Battery Temperature Humidity and Vibration Test Machine

-

RT-315 Programmable Laboratory Electronic Part Dustproof Test Chamber

-

RT-312 Dynamic Rubber Ozone Aging Testing Chamber Price

-

RT-310 Thermal shock impact testing chamber

-

RT-302 Desktop Constant Temperature and Humidity Test Chamber

-

RT-301 Simulate Environmental Testing Chamber

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)