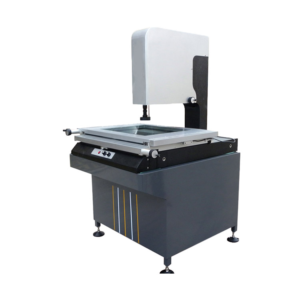

RT-1409 Automatic Coordinate Measuring Machine ( Gantry type)

Product Details:

.jpg)

Main feature

Designed for measuring parts require large and large sizes designed to meet the aerospace, mold and parts manufacturing precision measurement needs.

The series There are two types available, each type provides excellent accuracy and efficiency, the customer can choose the appropriate model according to their needs.

Stroke range (mm):2000*3000*1000-2500*5000*180

MPE E=5+4L/1000

Sophisticated gantry measuring machine manufacturing technology

The accuracy of long-term stable and reliable

Careful design of finite element analysis technology reduces bias structure

Dual grating / dual-drive technology reduces the truss deflection

Real-time geometric error compensation, up to 26 parameters

Strong efficiency and flexibility

Low quality aluminum activities unit provides the highest speed and acceleration

Continuous trajectory interpolation technology (flight characteristics)

Servo system parameters are automatically optimized adjustment

Good system scalability

High load of machine design

Z-axis is equipped with pneumatic safety brakes

Cover a variety of configurations, suitable for use in a variety of occasions

Safe operation in the workshop environment

Y-axis guide free to expand without causing distortion

Thermal expansion coefficient of the grating after the official certification

Insulated housing configuration

Efficient temperature compensation system options: linear temperature compensation and temperature compensation structure

Technical Parameters:

| Description | 302010 | 602015 |

| Stroke | X axis: 2000mm Y axis: 3000mm Z axis: 1000mm

|

X axis: 2000mm Y axis: 6000mm Z axis: 1500mm

|

| Measuring space: | 2020mm * 3020mm * 1010mm | 2020mm*6020mm*1515mm |

| The maximum allowable length measuring indication error (μm): | MPEe = 6.0 + L / 250

|

MPEe = 6.0 + L / 250

|

| The maximum permissible probing error (μm): | MPEp = 6.0 | MPEp=8.0 |

| Grating Resolution (μm): | 0.5

|

|

| Structure models: | mobile gantry | |

| Transmission: | high-precision air bearing preload | |

| Machine: | precision granite platform | |

Environmental conditions:

Measuring Machine room temperature requirements: Temperature measuring machine room: 18-22 ℃

The maximum temperature gradient around the machine environment: 1 ℃ / h 2 ℃ / 24h, 1 ℃ / m

Gas supply system: Minimum supply pressure: 0.5Mpa Air consumption: 120L / min

Power supply system: Voltage: 220V ± 10%, the maximum power consumption: 2000W, Current: 15A

Electrical equipment requires reliable grounding: Grounding resistance less than 4 ohms

CMM software

Pipeline module: professional pipeline for data analysis

CAD drawings custom pipeline has the following advantages:

- Paint saving time

- realistic illustration pipeline, and the pipeline to facilitate intuitive and accurate comparison of the data

- Direct measurement, intuitive graphics, vivid, shorten the measurement time

- The measuring points can be generated based on theoretical data, convenient

Support curves and surfaces made open type

Point cloud support functions, point cloud import / export

Support 21 error compensation / Temperature compensation / real-time temperature compensation

Supports CAD import / export, and seamless CAD

CAD elements automatically take knowledge, CAD-based fast programming, real-time comparison

Laser scanning module: high precision for reverse engineering

Reverse engineering studies have been increasingly visible, the workpiece can be high-speed, high-efficiency, high-precision measurement, fast

Acquisition coordinate points, provide data for reverse engineering.

Laser scanning measuring object non-contact measurement, no damage to the surface of the soft texture or precious objects measuring more than advantages.

Adapted to detect a workpiece without CAD

DMIS5.0 Programming

Graphical display of the measured element, the machine model, the probe model

Graphical display of the entire process of detection, detection path Preview / real-time simulation

Graphical output report

Create a complete coordinate system, structure, form and position tolerances computing

3D module: comparison of the data for high-precision

1, generating 3D graphics pipeline based on the theory of intelligent data.

2, built pipeline coordinate the establishment of methods to facilitate the completion of constructing the pipeline coordinate system.

3, the definition of a variety of channels, the user can complete the pipeline in accordance with customary definition.

4, convenient and efficient completion of the measurement pipe, greatly improve the measurement efficiency.

5, a complete data and graphical output reports, the measurement data at a glance.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)