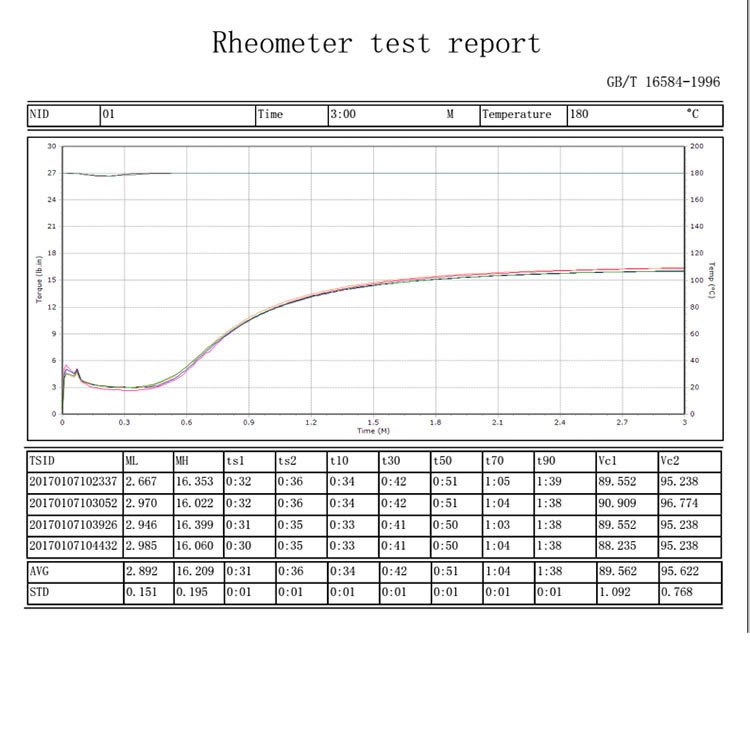

The word “vulcanization” has its own history. It was named after the initial natural rubber products were cross-linked with sulfur as a cross-linking agent. With the development of the rubber industry, a variety of non-sulfur cross-linking agents can now be used for cross-linking. Therefore, the more scientific meaning of vulcanization should be “crosslinking” or “bridging”, that is, the technological process of the network polymer formed by the linear polymer through crosslinking. From the physical properties of the rotorless vulcanizer, it is the process of converting plastic rubber into elastic rubber or hard rubber. The meaning of “vulcanization” includes not only the process of actual crosslinking, but also the method of producing crosslinking.

The main factors affecting the vulcanization process are the amount of sulfur, the vulcanization temperature and the vulcanization time.

1. The amount of sulfur.

The larger the dosage, the faster the vulcanization rate and the higher the degree of vulcanization that can be achieved. The solubility of sulfur in rubber is limited, and excess sulfur will be precipitated from the surface of the rubber compound, commonly known as “sulfur spray”. In order to reduce the phenomenon of sulfur spraying, it is required to add sulfur at the lowest possible temperature, or at least below the melting point of sulfur. According to the use requirements of rubber products, the amount of sulfur in soft rubber is generally not more than 3%, the amount in semi-rigid rubber is generally about 20%, and the amount in hard rubber can be as high as 40% or more.

2. Vulcanization temperature.

If the temperature is 10 °C higher, the curing time will be shortened by about half. Since rubber is a poor thermal conductor, the vulcanization process of the product varies due to the temperature difference of its various parts. In order to ensure a relatively uniform degree of vulcanization, thick rubber products are generally vulcanized at a gradual temperature and at a low temperature for a long time.

3. Vulcanization time.

This is an important part of the vulcanization process. If the time is too short, the degree of vulcanization is insufficient (also known as under-sulfur). If the time is too long, the degree of vulcanization is too high (commonly known as over-sulfur). Only a suitable degree of vulcanization (commonly known as positive vulcanization) can ensure the best comprehensive performance.