Rubber Low Temperature Brittleness Tester (RT-103)

RT-103 Rubber Low Temperature Impact Embrittlement Tester

It is used to measure the highest temperature when vulcanized rubber is impacted to cause damage under special conditions, and the temperature is called the brittle temperature.

Product Details:

Equipment Summary

The rubber low-temperature brittleness tester is the highest temperature at which the sample is damaged by impact under the specified conditions, that is, the brittleness temperature, which can be used to compare the performance of plastics and other elastic materials under low temperature conditions. It can measure the brittleness temperature and low-temperature performance of vulcanized rubber from different rubber materials or formulations. Therefore, it is indispensable in the quality inspection of scientific research materials and their products, and the control of production processes. The instrument is designed according to the GB1682 national standard. The technical indicators meet the requirements of HG 2-162-1965 plastic low temperature impact compression test method and GB5470-2008 plastic impact embrittlement temperature test method.

Comply Standard:

ISO 812

ISO 974

GB/T 15256

GB/T 5470-2008

GB/T 1682

HG2-165-65

ASTM D746

Technical Parameters

| Test temperature and time: | -70 ℃ ~ 0 ℃ (normally more than 1 hour) |

| Impact speed: | 2m/s±0.2m/s |

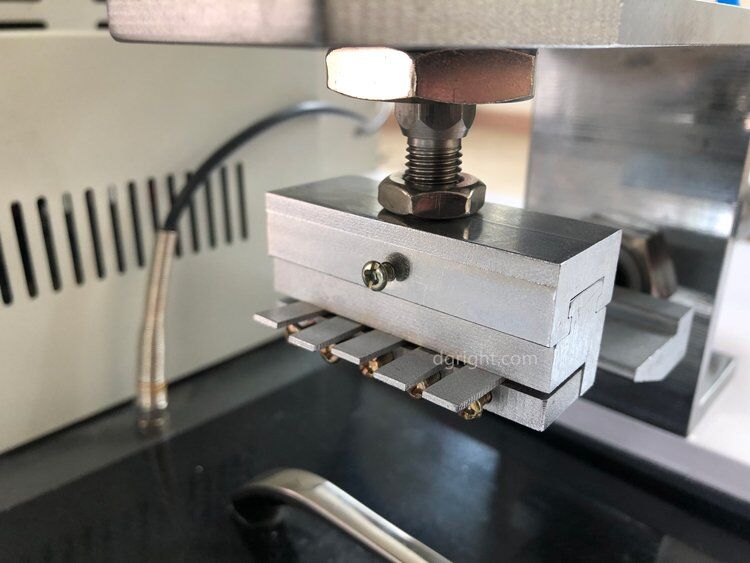

| Impact head radius: | single sample method: R1.5 ± 0.1mm multi-sample method: R1.6 ± 0.1mm |

| After the constant temperature, the temperature fluctuation during the test was within 3 minutes: | <±0.5°C fluctuation is slight, and the temperature control is more accurate |

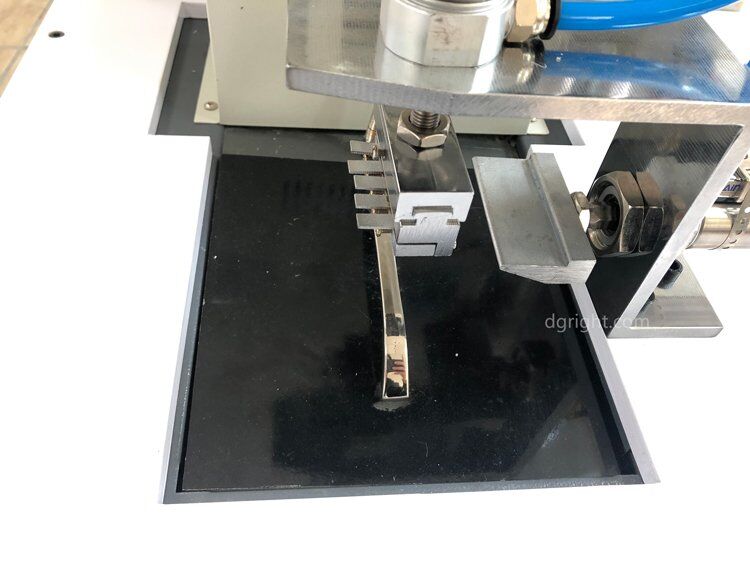

| Distance from the center of the impactor to the lower end of the holder: | 11 ± 0.5mm (single sample method), 8 ± 0.3mm (multi-sample method) |

| Sample size: length: | 25.0 ± 0.5mm, width: 6.0 ± 0.5mm, thickness: 2.0 ± 0.3mm |

| Machine size: | 910×510×860mm |

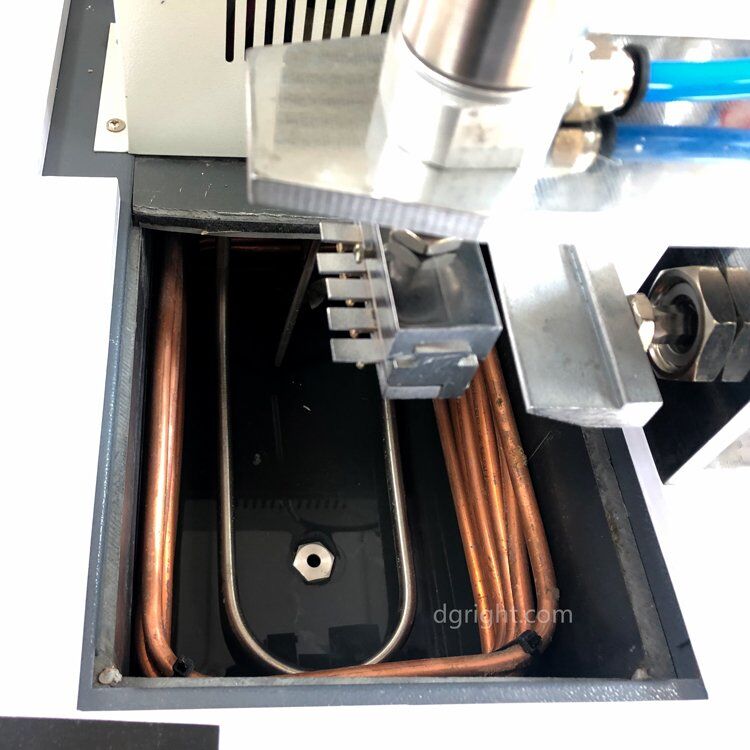

| Studio size: | 240×170×150mm (length × width × height) |

The Method of Use

3.1 Turn on the power, and the temperature controller and timer display lights.

3.2 Inject cold medium (usually industrial ethanol) into the cold well, and the injection amount should ensure that the distance from the lower end of the holder to the liquid surface is 75±10mm.

3.3 Hold the specimen vertically on the holder. The clip should not be too tight or too loose to prevent the sample from deforming or falling off.

3.4 After the test temperature is reached, press the start button, the test machine will work automatically (press the gripper, start freezing the sample, start the timing control switch or press the stopwatch. The sample freezing time is specified as 3.0±0.5min. During the freezing period, the temperature of the freezing medium should not exceed ±1 °C)

3.5 Remove the sample and bend the sample to 180° in the direction of impact. Observe the damage carefully.

3.6 After the sample is impacted (only one impact per sample), if there is damage, the temperature of the freezing medium should be increased; otherwise, the temperature will be lowered, and the test will continue.

3.7 Temperature adjustment method: a, press the set button, the temperature controller enters the setting state

- Press the “<” button to move to the position you want to set.

- Press the “∧” button to adjust the temperature.

d, press the “set” button to confirm

Through trial and error, the lowest temperature at which at least two samples are not destroyed and the highest temperature at which at least one sample is destroyed are determined. If the difference between the two results is not more than 1 ° C, the test is finished.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

Automatic Opening and Closing Rubber Dispersion Kneader (RT-123)

-

RT-110 Botton Type Two Roll Open Mixing Mill (Electronic Heating & Water Cooling)

-

Lab Oil Heating Two Roll Mill ( 12 inch or above)

-

RT-110A Button Type Two Roll Mill (Adjustable Speed Ratio)

-

RT-117A Pointer Type Thickness Gauge

-

RT-108 Rubber Compression Rebound Tester

-

RT-110A Rubber Two Roll Mill Machine (electrical heating)

-

Professional Manufacturer Offer Lab Rubber Mooney Viscometer Price (RT-102)

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)