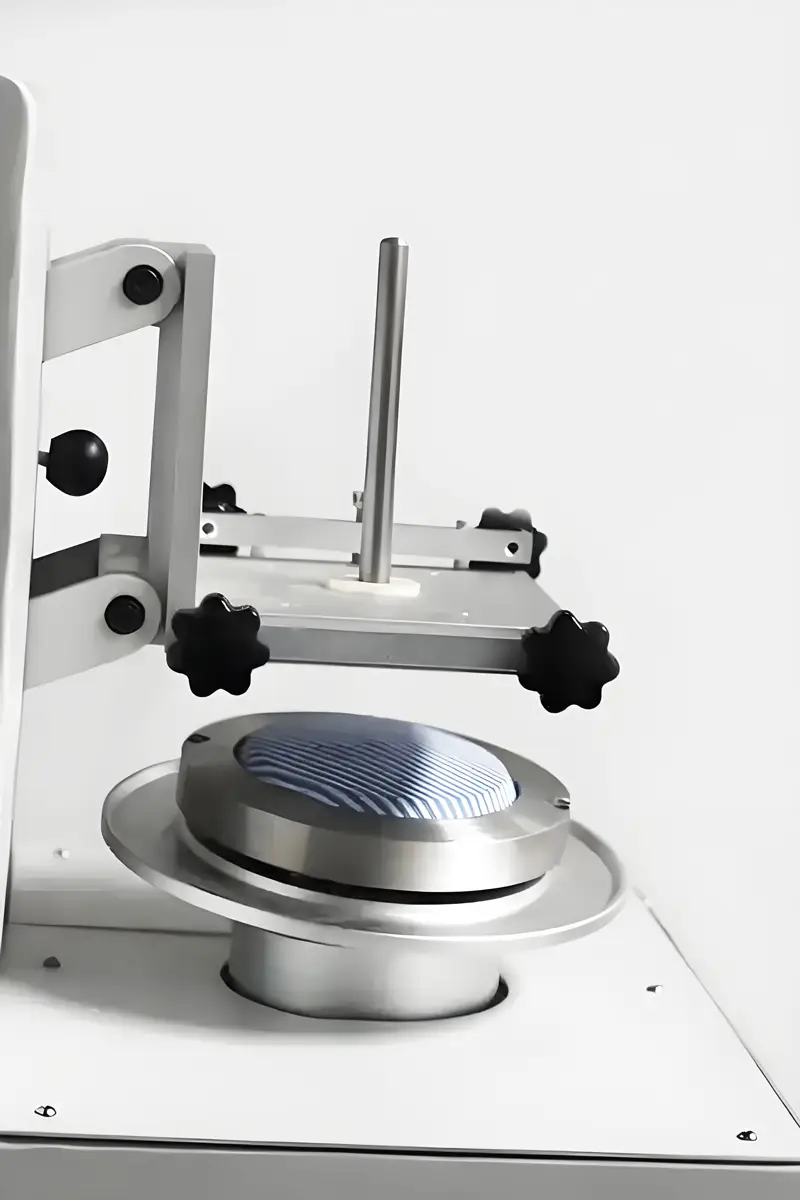

DIN 53863 Textile Schopper Abrasion Tester (RT-858)

CIRCULAR SCRUB TESTER (SCHOPPER system)

This machine is for testing the abrasion resistance of textile fabrics (woven fabrics, knitted fabrics etc.) in accordance with DIN 53863, Part 2, GME Standard 60345, GMW Standard 3283 and VW/Audi central standard PV 3908.

Product Details:

Touch Screen Schopper Rotary Abrasion Tester

Application:

For testing the abrasion resistance of textile fabrics (woven, knitted, etc.). The working principle is that a friction body exerts a scouring effect in the tangential direction on the rotating specimen. The circular scuffing test can be used as a scuffing test, as a scuffing test to assess the change in fabric appearance or as a through scuffing test. It is recommended to refer to the standard sheets for details.

Specification:

|

Item

|

Detail

|

|

Rotational speed

|

75 r/min

|

|

Cone angle

|

166°

|

|

Sample area

|

100cm², round sample with diameter 11.28mm

|

|

Abrasion area

|

50cm²

|

|

Specimen curvature

|

5mm

|

|

Loading weight

|

50g, 100g, 250g, 500g, 1000g, 1500g;

|

|

Loading pressure

|

Weight/m² of the sample

up to 100 – 1.0N 100 to 150 – 2.0N 150 to 300 – 5.0N above 300 – 10.0N |

|

Power supply

|

110V, 220V 50Hz

|

|

Dimension

|

460mm×560mm×510mm(L×W×H)

|

|

Net weight

|

80kg

|

Comply Standards:

In accordance with DIN 53863, Part 2, GME Standard 60345, GMW Standard 3283 and VW/Audi central standard PV 3908.

Instrument Characteristics:

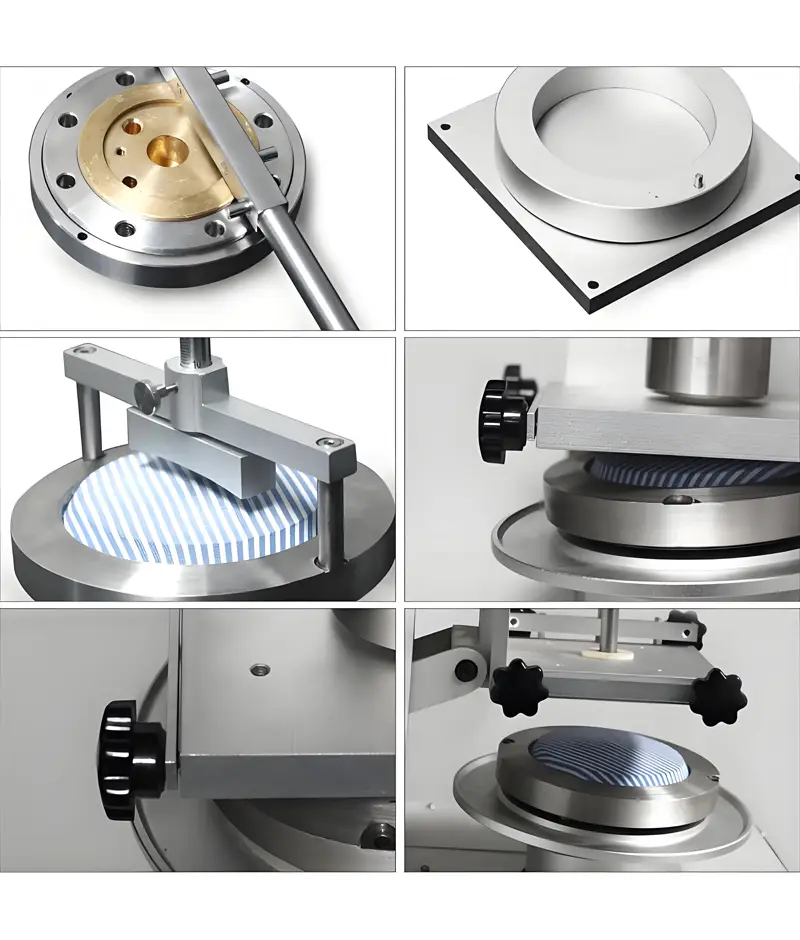

Test Method:

- Use the accessories configured by the instrument to install the sample that has undergone temperature and humidity treatment onto the sample fixture, forming a rotating test head;

- Use an arch height testing device to adjust the protrusion height of the testing head according to relevant standards or other requirements, generally ranging from 5 to 8mm;

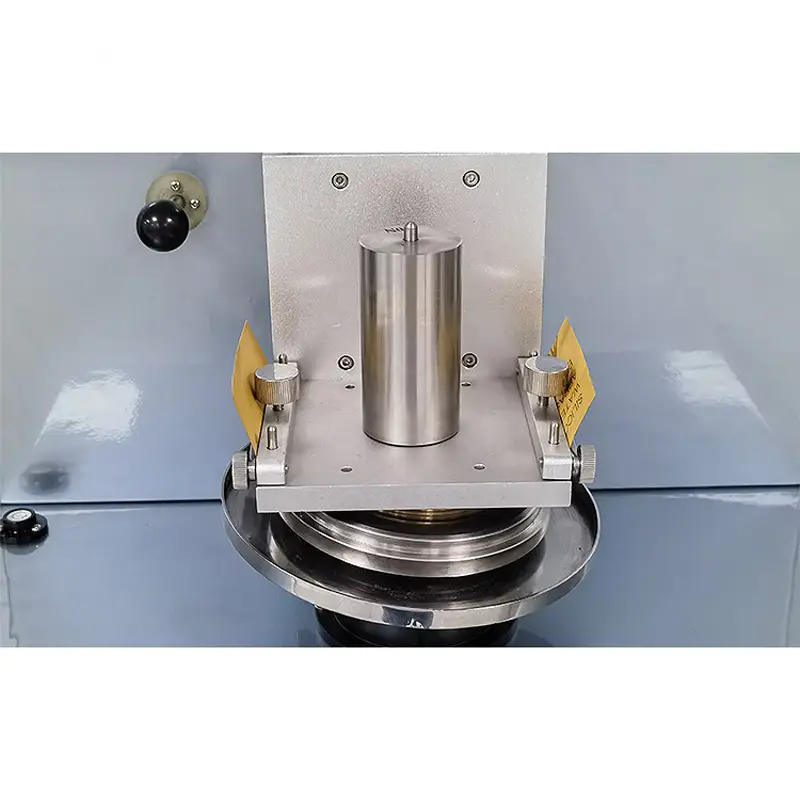

- Install the test head with the sample on the test head mounting plate on the instrument workbench, and install and tighten the test head by matching the positioning tip on the mounting plate with the positioning hole below the test head;

- Use the friction material fixture located on the pressure plate of the instrument to install the friction sandpaper on the lower surface of the pressure plate, lock the fixture to ensure that the sandpaper is clamped and installed smoothly;

- Manually pull the pressure plate lifting lock located on the right side of the pressure plate outward to lower the pressure plate, so that the sandpaper comes into contact with the surface of the sample on the test head;

- Install weights corresponding to the weight on the weight shaft above the pressure plate (equipped with one standard weight of 1500, 1000, 500, 250, 100, and 50g each), and apply a certain pressure to the friction of the sample. Select the required pressure value based on the weight of the sample per unit area.

Working Principle:

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-824 Knitted / Nonwoven / Stretch Woven Fabric Diaphragm Mullen Bursting Strength Tester

-

RT-823 Stoll Quartermaster Universal Friction Abrasive Wear Tester

-

RT-839 High Temperature IR Fabric Dyeing Machine, Lab Infrared Textile Dyeing Machines

-

RT-812 Fabric Air Permeability Testing Machine

-

RT-811 Textile Fabric Washing Colour Fastness Tester

-

RT-807 Geotechnical Cloth Perspiration Test Oven For Color Fastness Testing

-

RT-805 Geosynthetics Wear Resistance Tester

-

RT-802C Auto Textile Crockmeter Rubbing Fastness Tester

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)