ASTM ISO Standard Box-Type UV Aging Chamber with Touch Screen Simulation Sunlight Rain and Dew Test Equipment (RT-308B)

RT-308B UV Accelerated Aging Test Chamber

UVA-340 Accelerated Aging Test Chamber

The UVA-340 fluorescent UV lamp is used as the light source to simulate sunlight, rain, and dew, reproducing outdoor weathering in a controlled and accelerated environment.

During the test, samples are exposed to alternating cycles of UV light and moisture at a set temperature. Within days or weeks, the chamber can simulate months or years of natural aging. Typical damages include fading, discoloration, cracking, chalking, turbidity, brittleness, and oxidation.

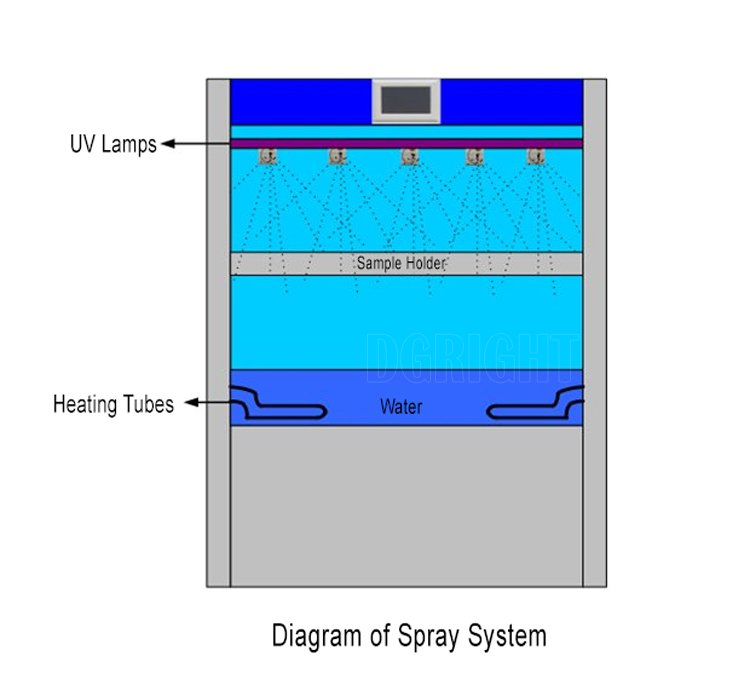

The chamber features a spraying device to simulate rainfall and can recreate multiple environmental conditions such as UV, high temperature, humidity, condensation, and darkness.

It automatically monitors black panel temperature and water bath temperature for stability. With an optional irradiance control system, the light intensity can be kept at 0.76 W/m² @ 340 nm or a preset value, extending the lamp lifespan and ensuring consistent test results.

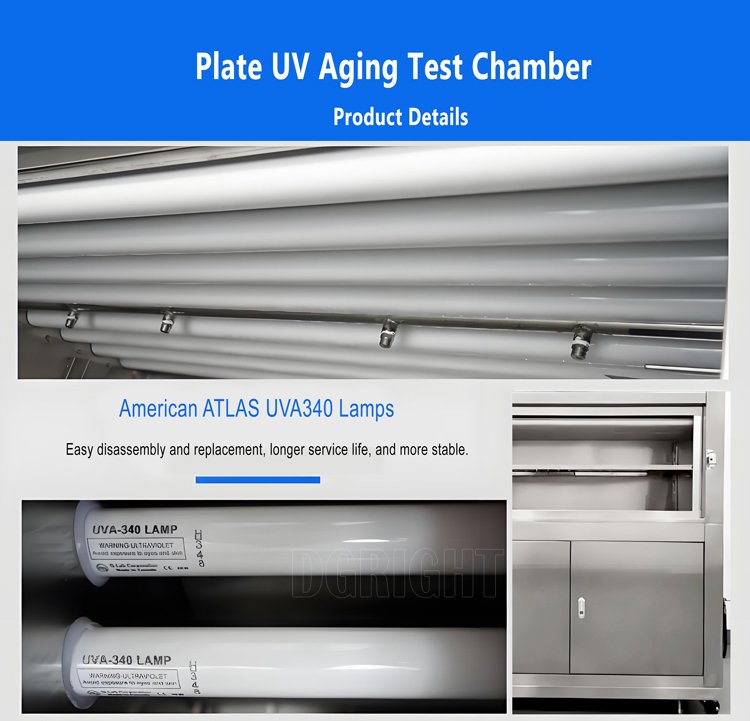

Product Details:

I. Equipment Summary

II. Meet Standard

III. Structural Material

|

1. Test chamber dimensions:

|

1050 × 600 × 450 mm

|

|

2. Overall dimensions:

|

1400 × 770 × 1630 mm

|

|

3. Unit Material:

|

304 stainless steel interior and exterior

|

|

4. Specimen Rack:

|

Aluminum alloy frame with viewing panel

|

|

5. Controller:

|

TIMI880 (Full-touch programmable controller)

|

|

6. Power Supply:

|

Ground fault circuit interrupter with overload/short circuit alarm, over-temperature alarm, and low-water protection

|

IV. Technical Specifications

V. Structural Specifications

VI. Safety Protection Devices

VII. Temperature Control

VIII.Heating System

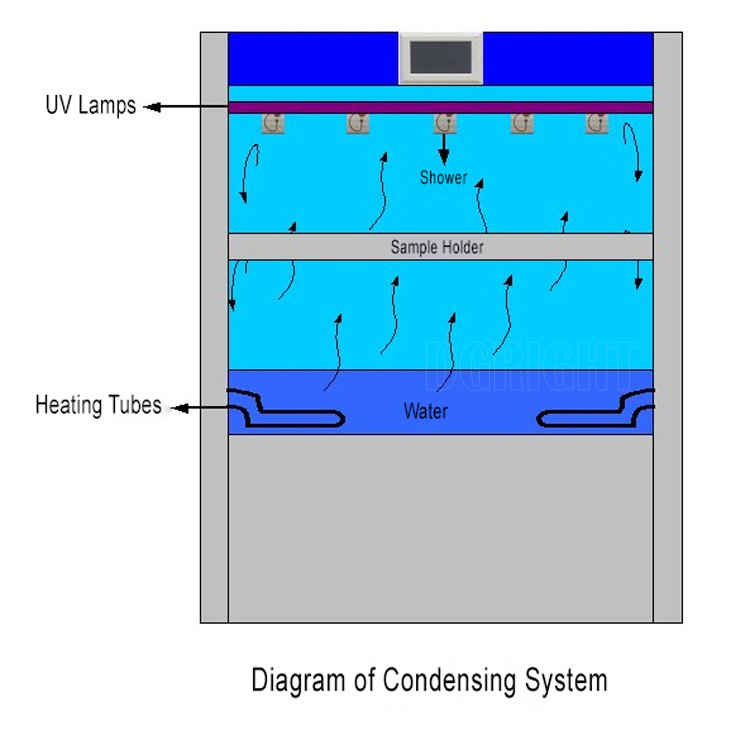

2) Water bath temperature is controlled by a color touchscreen programmable Korean temperature controller. The water bath is located at the bottom of the chamber and incorporates an electric water heater. During testing, one phase involves a dark condensation process requiring the chamber to generate saturated water vapor at elevated temperatures. When this vapor encounters the relatively cooler specimen surface, condensation forms dew on the specimen.

IX. Equipment Operating Conditions

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

ASTM D5423 Air Ventilation Aging Climatic Test Chamber (RT-326)

-

RT-308A Desktop UV Accelerated Aging Testing Chamber

-

RT-321 SO2 Gas Spray Sulfur Dioxide Test Chamber

-

RT-318 Laboratory Battery Temperature Humidity and Vibration Test Machine

-

RT-312 Dynamic Rubber Ozone Aging Testing Chamber Price

-

RT-311 Salt Spray Corrosion Testing Chamber

-

RT-309 Desktop Xenon Weathering Testing Chamber

-

RT-304A Walk-in Constant Temperature and Humidity Test Chamber

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)