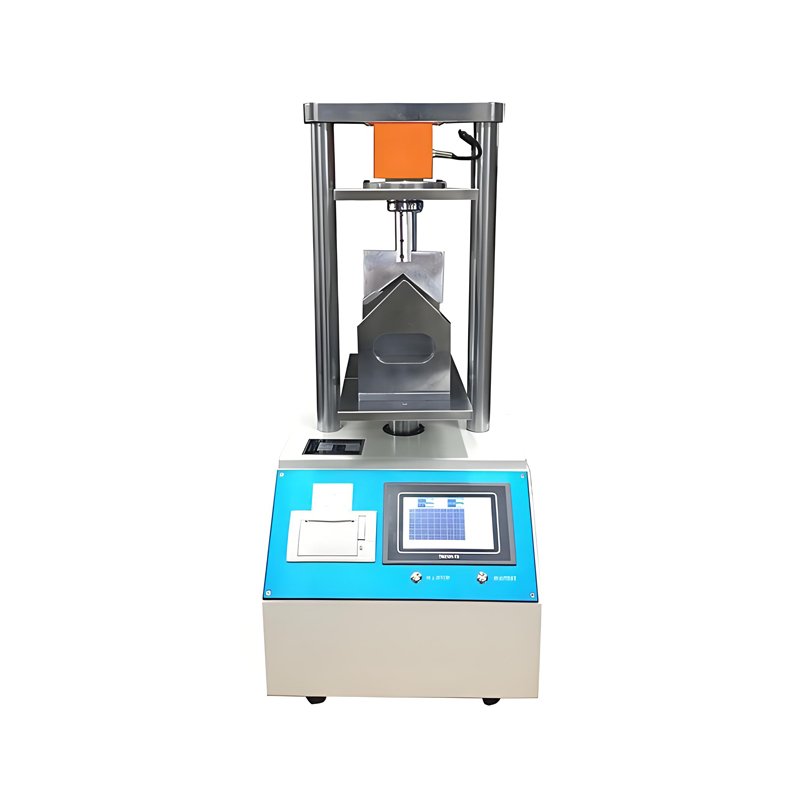

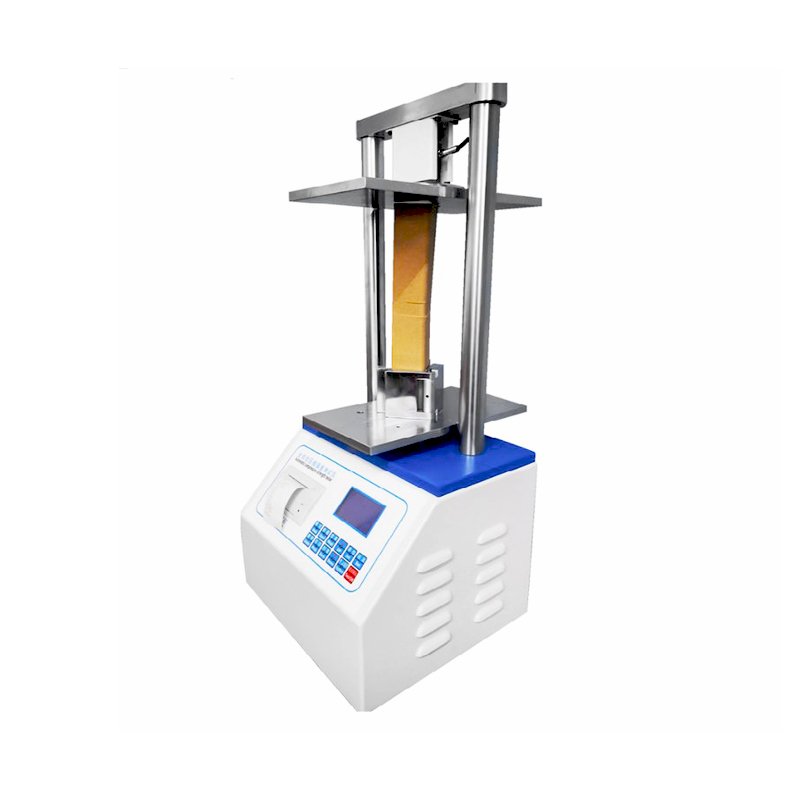

High-Precision Paper Corner Strength Tester | Packaging Compression Testing Machine (RT-445)

Additional information

| Model | RT-445 |

|---|---|

| Test direction | vertical, horizontal |

| Measurement range | 10~10000N |

| Return speed | 1~60mm/min |

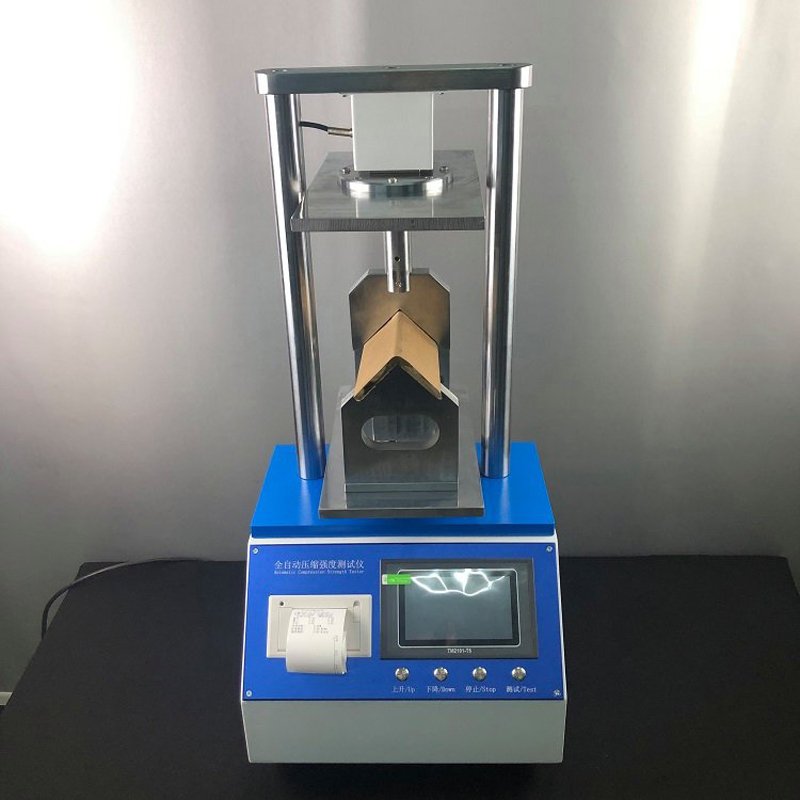

Edge Protector Compression Tester— High-Precision Compression & Bending Testing Machine

Fully automatic testing, automatic reset, automatic calculation of test results, direct printing of test results, fully meeting QB/T1048 BB/T 0023-2004 testing standards

Product Details:

1. Product Overview

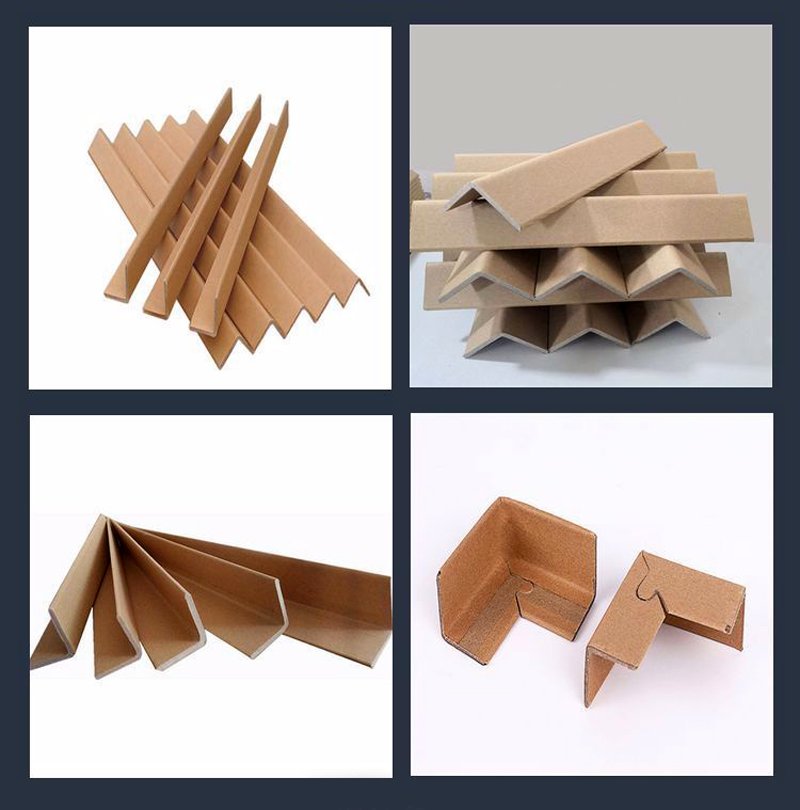

The Paper Corner Strength Tester is designed to measure the compressive and bending strength of paper corner protectors (L-shaped, U-shaped, laminated, or folded edge protectors). It ensures packaging durability during storage, transportation, and handling.

Who Needs It:

- Paper corner protector manufacturers

- Packaging material suppliers

- Logistics & shipping companies

- Quality control laboratories

- Certification agencies

Why Choose This Tester:

- Reduce packaging damage and logistics costs

- Guarantee compliance with international standards

- Optimize material design with reliable test data

2. Key Features & Advantages

| # | Feature | Customer Benefit |

|---|---|---|

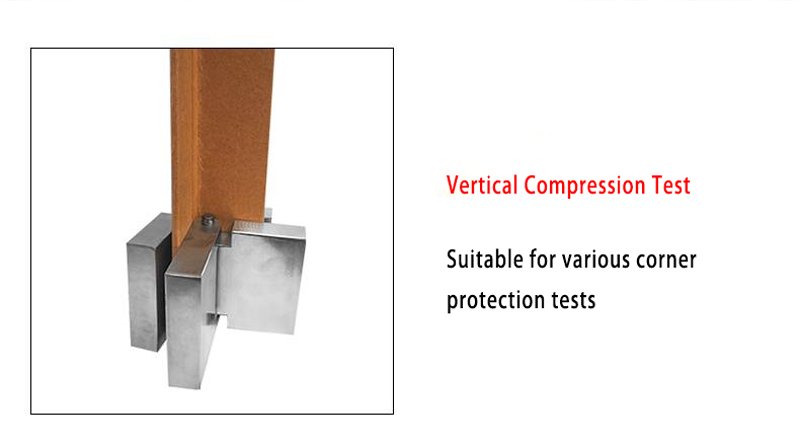

| 1 | Dual Test Modes: Vertical compression & horizontal bending | Provides a complete evaluation of edge protector strength |

| 2 | High-precision load cell with 24-bit AD converter | Delivers accurate and repeatable test results |

| 3 | 7-inch color touch screen with force–deformation curve display | User-friendly interface with real-time visualization |

| 4 | Overload protection & power-off memory | Protects equipment and ensures data integrity |

| 5 | Standard Compliance: Meets BB/T-0023 & ISO requirements | Trusted by labs and QC departments |

| 6 | Data Output & Connectivity: USB / RS-232 / PC software | Easy report generation and long-term storage |

3. Technical Specifications

| Item | Specification |

|---|---|

| Load Range | 10 N – 10000 N |

| Accuracy | ± 2% |

| Resolution | 0.01 N |

| Max Deformation Error | ±1 mm |

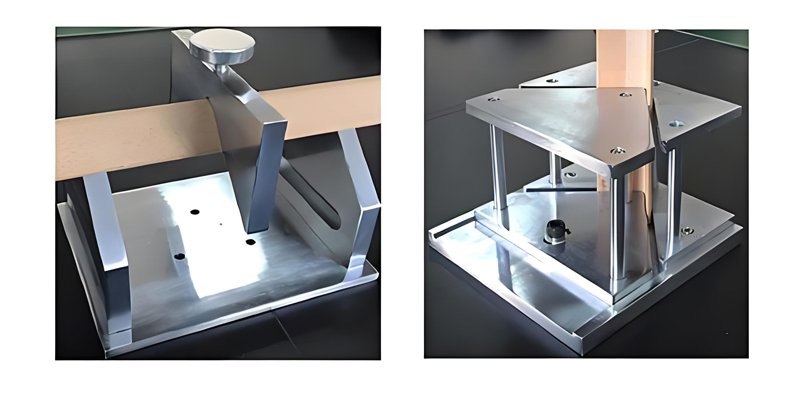

| Compression Plate Size | 300 × 300 mm |

| Parallelism | ≤1 mm |

| Travel Range | 5 – 300 mm |

| Sample Length | 300 mm |

| Vertical Test Speed | 10 ± 2 mm/min |

| Bending Test Speed | 100 ± 10 mm/min |

| Display | 7-inch color touch screen |

| Power Supply | AC 100–240 V, 50/60 Hz |

| Operating Environment | Temp. 10–35 ℃, Humidity ≤85% RH |

| Dimensions | e.g. 535 × 425 × 805 mm |

| Weight | Approx. 80 kg |

4. What’s Included

- Main testing unit ×1

- Power cable ×1

- User manual ×1

- Warranty card / Quality certificate ×1

- Calibration certificate (optional)

5. How to Use

- Place the paper corner sample on the compression plate (vertical or horizontal).

- Select the test mode (compression/bending), load range, and test speed.

- Start the test – the machine automatically applies force until failure or pre-set limit.

- Monitor real-time force–deformation curve on the touch screen.

- Export or print results for analysis and quality documentation.

6. Standards & Certifications

- Complies with BB/T-0023 and ISO standards

- Factory calibration included

- Optional third-party calibration certificate is available

- Manufactured under ISO 9001 quality management system

7. Applications

- Production line testing: Ensure paper corner protectors meet quality requirements before shipment

- Material cost evaluation: Compare strengths of different materials and thicknesses

- Independent laboratories: Provide third-party verification and test reports

- Custom design validation: Support R&D for stronger and cost-effective paper corners

8. FAQ

Q1: What sample size is required?

A: Standard sample length is 300 mm; thickness and width depend on your paper corner, as long as it fits the compression plate.

Q2: How can I maintain testing accuracy?

A: Keep the compression plates clean, calibrate the load cell regularly, and store in a dry environment.

Q3: What if the machine malfunctions?

A: We provide a 12-month warranty, spare parts supply, remote support, and on-site service (depending on region).

9. Trust & Reliability

- Trusted by leading packaging and logistics companies

- CE / ISO / RoHS certification available (if applicable)

- Real product photos & videos (showing test in progress)

- Customer testimonials and case studies

10. Ordering Information

- Price Terms: FOB / CIF / EXW (contact us for a quotation)

- Lead Time: 3–7 days for standard models; customized options available

- Payment Terms: T/T, L/C, or negotiable

- Packaging: Export wooden case with anti-shock protection

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-425 Plastic Film COF Tester Paper Inclined Surface Coefficient Friction Tester

-

RT-424 Laboratory Wet Disintegration Paper Pulp Disintegrator

-

RT-421 Package Incline Impact Testing Machine

-

RT-416 Cardboard Puncture Strength Tester

-

RT-415 FCT Sample Cutter Corrugated Board Flat Press Sampler

-

RT-407 Paper and Cardboard Thickness Tester

-

RT-404A Pointer Type Paper Tearing Strength Tester

-

RT-403A Digital Single Wing Packaging Carton Box Drop Tester

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)