Why Choose Our Rubber Mooney Viscometers?

As a specialized manufacturer of Mooney Viscometers with 10+ years of industry expertise, we provide high-precision, ultra-stable Mooney viscosity testing solutions for global rubber, tire, sealing components, and hose industries. Our instruments strictly comply with ASTM D1646, ISO 289, GB/T 1232 international standards and carry CE certification, ensuring reliable performance for your quality control, R&D, and production needs.

Critical Role & Technical Principles of Mooney Viscometers

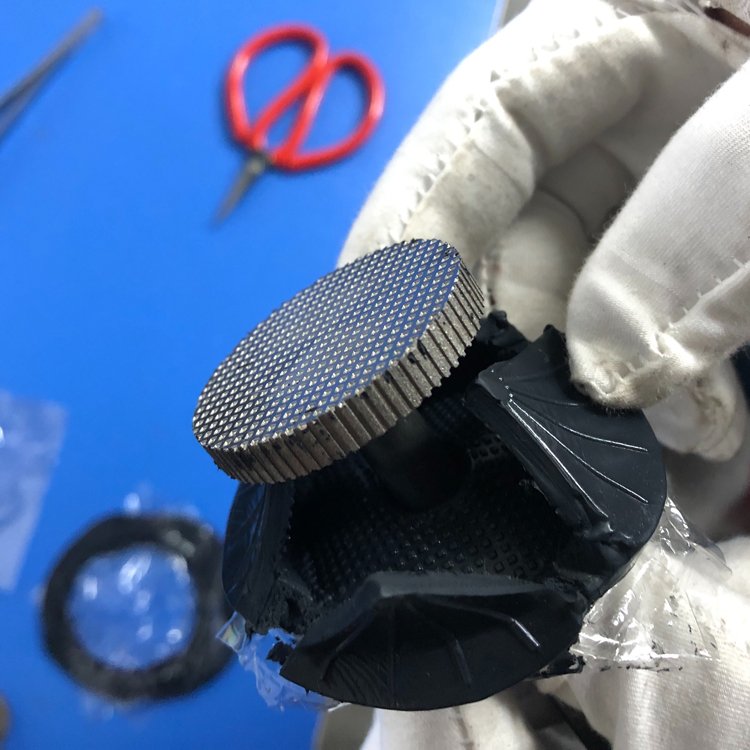

Mooney Viscometers are indispensable testing equipment in rubber processing, measuring the rheological properties of unvulcanized rubber. The principle involves rotating a rotor in a sealed cavity while measuring the sample’s resistance (torque) to calculate Mooney Viscosity (ML).

Key Test Parameters & Significance

| Parameter | Symbol | Significance | Application Value |

|---|---|---|---|

| Minimum Mooney Viscosity | ML(1+4) | Characterizes rubber processability | Evaluates mixing uniformity |

| Scorch Time | ts1/ts2 | Onset time of vulcanization | Prevents premature curing |

| Optimum Cure Time | t90 | Time to 90% vulcanization | Optimizes curing process |

| Cure Rate | Δ30 | Difference between t90 and ts1 | Assesses vulcanization efficiency |

Core Advantages & Technical Features

1. High-Precision Measurement System

- Temperature Control: PID intelligent control (±0.1°C, RT~200°C)

- Torque Measurement: High-sensitivity sensor (resolution ≤0.1 MU)

- Repeatability: Deviation <±0.5 MU (NIST-certified standard samples)

2. Intelligent Operation System

- Computer control (multi-language support)

- Professional software for real-time:

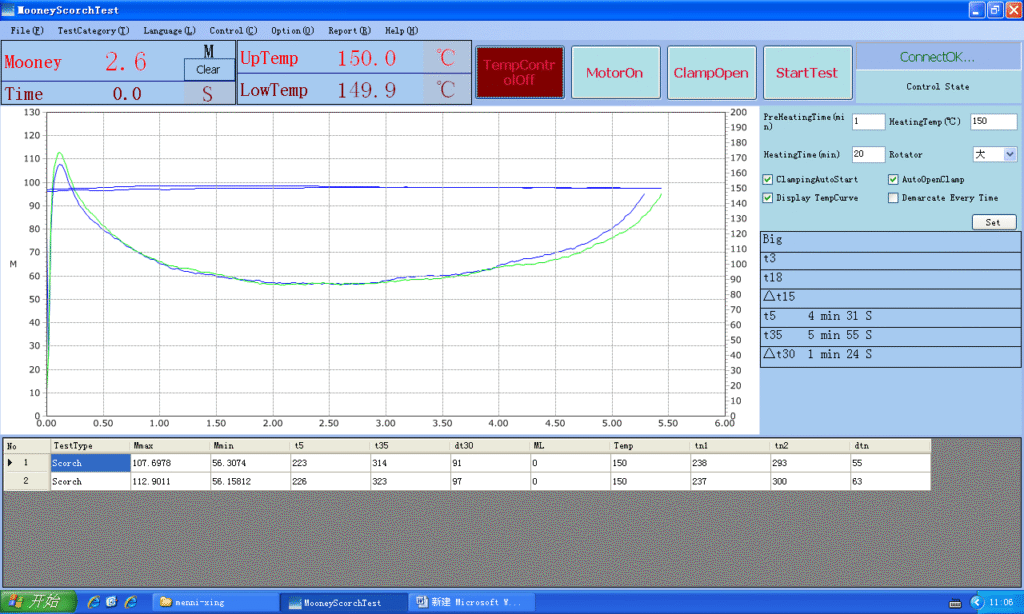

- Mooney viscosity-time curves

- Scorch behavior analysis

- Vulcanization rate profiling

- Data Management: 1,000+ dataset capacity (Excel/PDF export)

3. Robust Mechanical Design

| Component | Material | Features |

|---|---|---|

| Rotor | Specialty alloy steel | Hardened surface, wear/corrosion-resistant |

| Die Cavity | Chromium-molybdenum alloy | Precision-machined (±0.3°C uniformity) |

| Drive System | Precision bearings | Maintenance-free design (>10-year lifespan) |

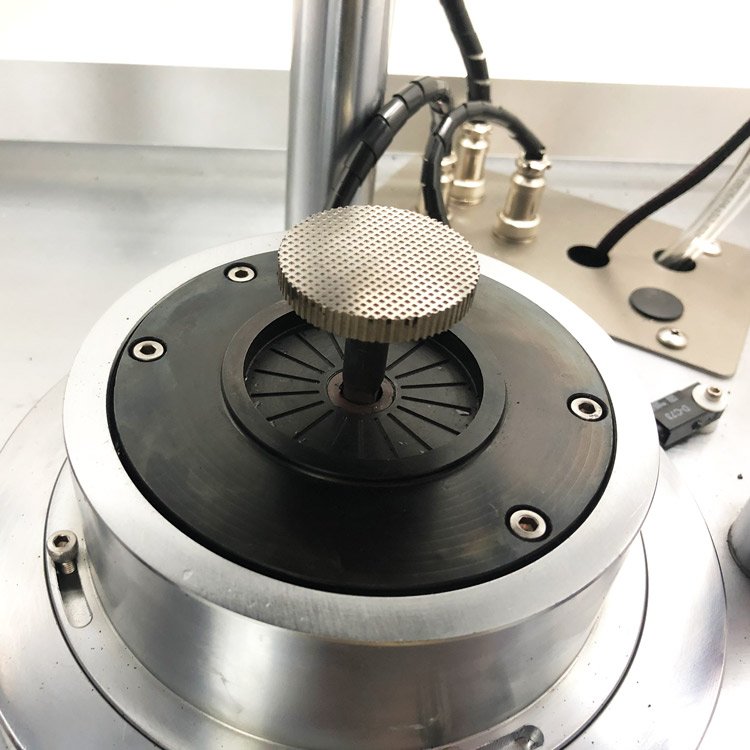

Fig 2: Core Component Diagram

4. Safety & Expandability

- Triple Safety Protections: Overload cut-off, overtemperature alarm, emergency stop

- Optional Modules:

- Dual-station testing (2x efficiency)

- Remote monitoring system (Industry 4.0 compatible)

- Automated cleaning system

Industry Application Cases

Case 1: Leading Tire Manufacturer

- Issue: Batch-to-batch Mooney variation (±5 MU)

- Solution: Implemented M-3000 Mooney viscometer QC system

- Result: Variation reduced to ±1 MU; scrap rate ↓30%

Case 2: Rubber Seals Supplier

- Requirement: Precise scorch time measurement

- Solution: Custom Mooney viscometer with rapid heating (3 min to 150°C)

- Outcome: Productivity ↑25%; energy consumption ↓15%

Technical Specifications Comparison

| Model | RT-102 |

| Control temperature range | Normal temperature~200℃ |

| Temperature display resolution | 0.01℃(0.1 ℃ common type of imported temperature controller temperature) |

| Temperature control accuracy | ±0.3℃ |

| Calibration accuracy | Mooney value ±0.5 |

| Rotor speed | 2 rotation/ min ±0.02rotation/ min |

| Torque range | Mooney value 0~200 |

| Torque resolution | Mooney value 0.1 |

| Print content | Date, time, temperature, Mooney scorch curve and MV,T5,T35,T3,T18,@15,@30 |

| Power | 50HZ, ~220V±10% |

Download full specs:

5 Reasons to Partner With Us

- Certified Accuracy: NIST-traceable calibration for every instrument

- Intelligent Efficiency: 40% faster testing vs. conventional systems

- Extended Durability: Critical components rated for 10+ years

- Global Support: Technical centers in 15 countries

- Custom Solutions: Tailored configurations for specialized needs

Technical FAQs

Q: How to calibrate the Mooney viscometer?

A: power calibration and setting

1. Confirm the connection is correct. You can power on the computer and click on the desktop.

Note: On/off computer interval>1min。

2. Introduction and test parameters for the main screen soft key settings:

Viscosity test: Click on the button, and the screen will display the viscosity test parameter settings” screen. You can set the six parameters; Click the test button, then enter the “viscosity test screen”.Click on the main screen, and you return to the main screen.

Scorch test: Click on the screen to enter “the scorch test parameter settings” screen—the same as others.

Viscosity database: Click on the button, and the screen will display “the picture of the viscosity test database”. Users can query and print a viscosity test for a group of historical curves and data.

Scorch database: Click on the screen to enter the “scorch test database screen”—the same as others.

Product Description: Click on the button, and the screen will display the “Introduction” screen.

Instructions for use: Click on the button, and the screen will display “instructions”.

Debugging: Click on the button for factory use.

Quit: Click on the button, the instrument ends, waiting for the shutdown.

Explain: Once set, the parameters above will be automatically saved.

Reboot, such as the constant need to reset.

Q: How to troubleshoot abnormal results?

A: This instrument is computer-controlled high degree of automation and easy operation. But the internal structure is complex, a precision instrument to normal operation, prolonging life, the user must do the daily maintenance work:

- Often, to keep the instrument inside and outside clean, but does not allow use with corrosive organic solvents, gasoline, wipe the surface;

- Good lubrication, the following provisions and fuel;

1) Column of the cavity regularly with a soft silk stained with oil and wipe it again:(Once every two weeks)

2) Filling the right amount of grease to the copper gear on a regular basis.: (Once every month)

- Pneumatic FRL: It should be noted that timely water and fuel (can not be wrong), and often pay attention to the mist atomization situation.(Generally regulate the opening and closing in each mode 2-3 times, there is a second drop of oil appear.)Every three months, at the same time as cleaning the filter, it is necessary to prevent the electromagnetic valve plug from failing due to action.

- Pressure gauge every six months (or year) to test again.

- At the end of each test, the cavity tank viscose should be cleaned up in time to prevent slipping and affect the test results.

- Printer manual for printer maintenance.

- Solenoid valve every 3-6 months, can be used with kerosene cleaning once dried, add a little oil in order to ensure the reliability of action (non-professional instrument work, this is done carefully)

- The instrument is disabled, such as a long time to heat up once every two weeks on the instrument power, each at least 15 minutes.

9. The electrical part of the maintenance checks:

1) First check the fuse is blown.( total power: 220V/10A 1).

2) If the fuse blows, do not rush to replace it with a new one to check out the reason.

3)Check the two switching power supply output is normal, if abnormal, should be immediately shut off the main power supply.

4)Check the electrical components, wiring, and other loose, fallen off, or short-circuited parts, and have them promptly repaired.

5)Computers, data acquisition boards, data conditioning boards, etc., do not fix it. If you have any questions contact the factory.

6)Calibrated once each year on the accuracy of platinum resistance temperature (with the factory to get in touch).

7)Panel buttons in case of damage, spare parts are replaced as soon as they are available to the user, and can not be inserted incorrectly.

10. Note:

1)Machine: If you have any questions, it should be turned off to prevent the failure to expand.

2)Machine fails, it is a timely self-test or a notice to specialized personnel to check the repair.

3)Our products implement year warranty, the insurance period, the factory can be sent maintenance.

4)The user should strictly adhere to the relevant contents of this manual, as operating in accordance with it can not be illegal.

11. Every two years to replace the trachea to prevent anti-aging fractures.

Q: Can you test high-temperature compounds (>200°C)?

A: Yes, custom models available (max. 250°C).

Request Your Customized Solution

📞 Hotline: +86-132-6746-6269

📧 Technical Inquiry: dgright@righttester.com

🌐 Website: https://dgright.com

📍 HQ: Wentang, DongCheng District 523000, Dongguan City ,Guangdong Province, PR China

Limited-Time Offers:

- Complimentary sample testing

- Online operational training

- Extended warranty program