Touch Screen Automatic Paper Cardboard Rupture Strength Tester (RT-406A)

Paper Corrugated Box Rupture Strength Testing Machine

Corresponding Standard: Automatic Rupture Strength Tester operative standardI:ISO-2759,GB-6545,JIS-P8112,L1018, ASTM-D2210,TAPPI-T403

Product Details:

RT-406A Paper Corrugated Box Rupture Strength Testing Machine

Specification

|

Model

|

RT-406A Automatic Rupture Strength Tester

|

|

Capacity choice

|

0~20, 50 kg/cm²can be set

|

|

Resolution

|

0.01 kg/cm²

|

|

Hydraulic speed

|

170±20cc/min

|

|

Hydraulic oil

|

glycerin 85%,distilled water15%

|

|

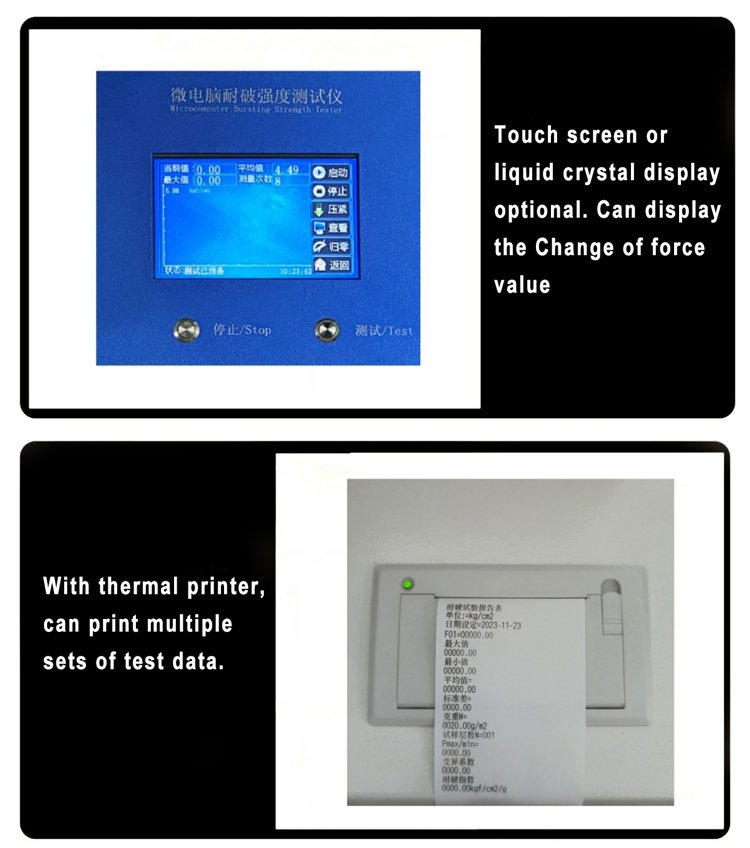

Display

|

PLC touch screen, can connect to a computer

|

|

Unit of force

|

kg/cm², KPa, or self-set

|

|

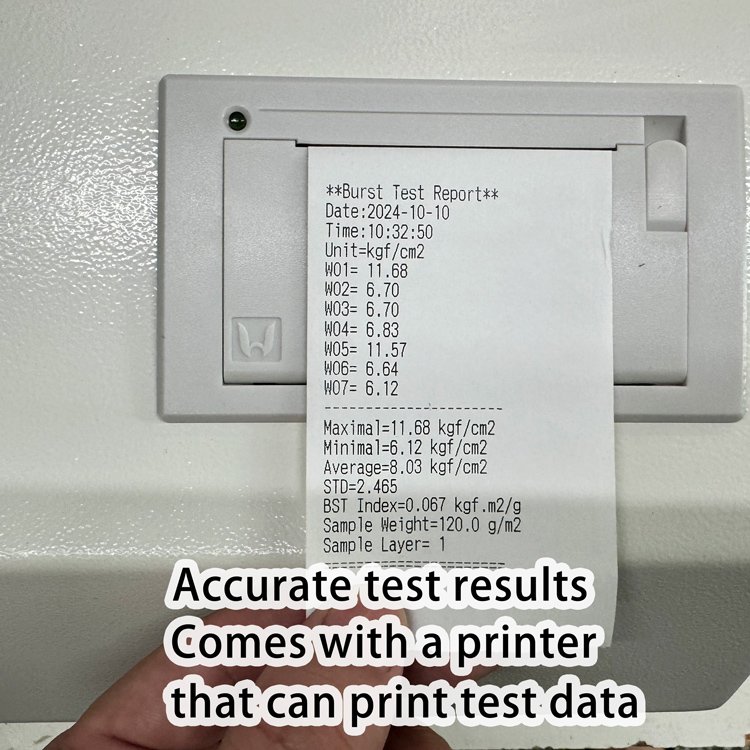

Specific feature tester with micro-printer

|

|

|

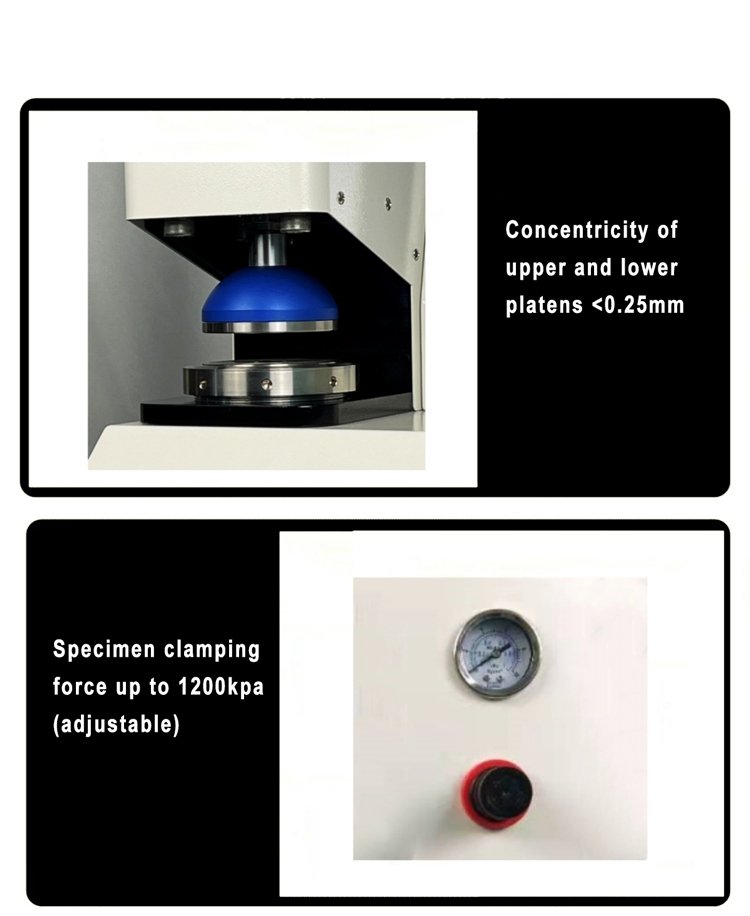

Clamping pressure

|

5kg/cm², adjustable

|

|

Air-pressure

|

min 6kg/cm² (customer-owned)

|

|

Volume

|

(W×D×H)56×47×55 cm

|

|

Weight

|

113kg

|

|

Power

|

AC220V,3A

|

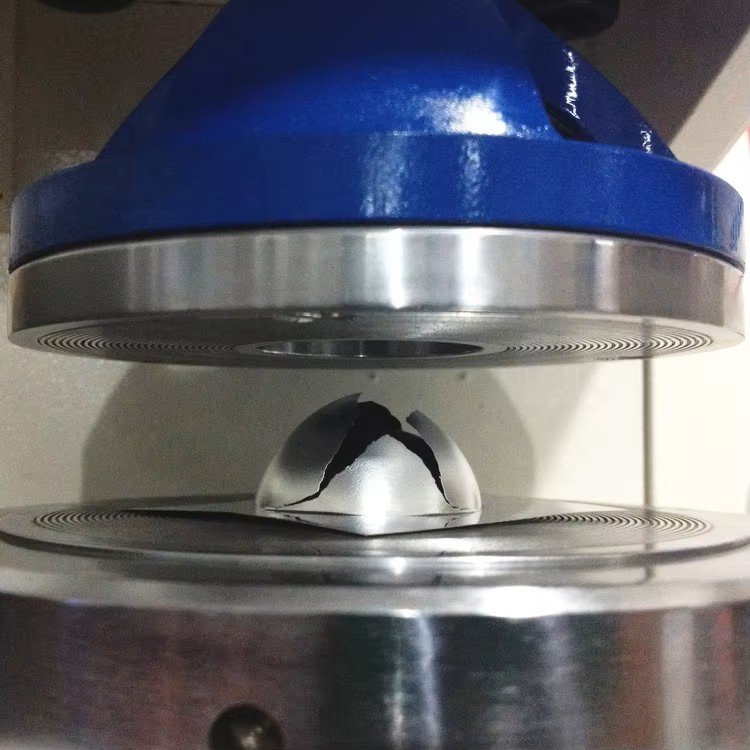

Rubber film convex disc pressure: convex height of 10mm, the resistance range is (170 ~ 220)kPa; Protruding 18mm, its resistance range is (250 ~ 350)kPa.

Applicable Industry:

Product Feature:

Installation Instructions:

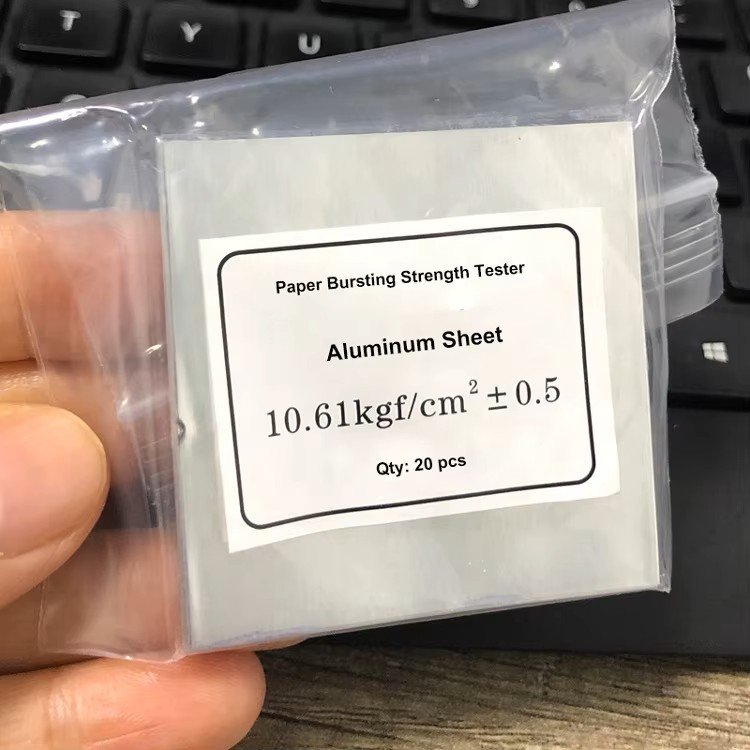

Film resistance check and film replacement:

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-426 ISO/ASTM Standard Ink Rub Resistance Tester

-

RT-411A Paper Cobb Test Machine, Cardboard Cobb Absorption Tester

-

RT-409 Paper Cups Body Stiffness Tester

-

RT-408A Paper Moisture Meter (induction type)

-

-300x300.jpg)

RT-404B Digital Fiber Film Paper Tearing Strength Test Machine

-

RT-404A Pointer Type Paper Tearing Strength Tester

-

RT-403A Digital Single Wing Packaging Carton Box Drop Tester

-

RT-401 BCT Carton Box Compression Test Machine Price

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)