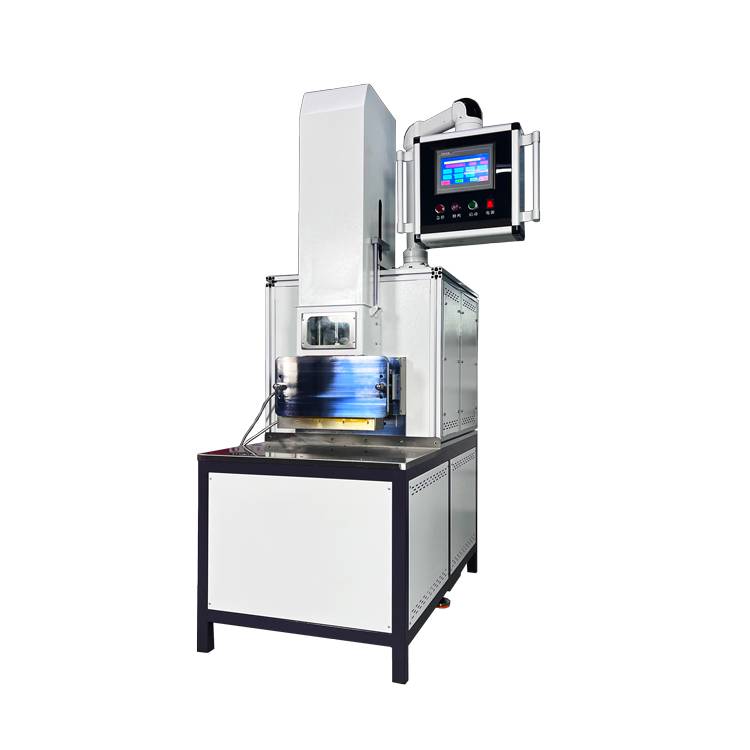

Automatic Opening and Closing Rubber Dispersion Kneader (RT-123)

Additional information

| Model | RT-123 |

|---|---|

| Capacity | 1L/2L/3L/5L |

| Temperature | RT~250℃ |

| Cooling method | Water cooling |

| Pouring method | Chamber opening and closing |

What is an internal mixer?

The RT-123 open-close type kneader mixer machine is mainly used for mixing rubber and plastic. It is easy to operate, produces uniform dispersion, and is suitable for laboratory formula development and small production.

Product Details:

What are the features of the RT-123 Lab Open-close Internal Mixer?

(1) The volume of the refining chamber: 1L/2L/3L/5L, a refining rubber 0.5-1kg, according to the density of the material; the greater the density, the greater the weight;

(2) Main motor: AC motor;

(3) Rotor: two-pronged, synchronous rotor structure (can also be designed and manufactured according to the rotor structure diagram provided by the user), front and rear rotor speed ratio of 1:1.3 or ST synchronous rotor, cast steel tempering hardening treatment, hard chrome-plated surface;

(4) control mode: manual, semi-automatic, and automatic;

(5) the maximum temperature of the refiner: RT-250 °;

(6) chamber wall: high-quality steel, heat treatment, internal surface hard chrome plating treatment;

(7) Upper top bolt: cylinder driven, surface hard chrome plated;

(8) Pouring method: automatic opening and closing of falling-type pouring material;

(9) Feeding hopper: manually operated.

What is the use of the RT-123 internal mixer?

What is the RT-123 kneader mixer structure?

RT-120 Internal mixer specifications:

| Model | RT-123 Type | ||||

| Mixing capacity | 1L | 2L | 3L | 5L | |

| Production capacity【Adjusted according to the softness or hardness of the material】 | 0.5-1KG | 0.8-2KG | 1-3KG | 2-5KG | |

| Temperature range | RT~250℃【Can be customized 300 degrees】 | ||||

| Heating method | Electrical heating | ||||

| Cooling method | Water cooling | ||||

| Display accuracy | 0.1℃ | ||||

| Controller | PLC programmable color touch screen, all process parameters can be set | ||||

| Pouring method | Automatic chamber opening and closing, material freely falling | ||||

| Reducer | Hardened gear reducer | ||||

| Maximum pressure of pressure weight | 0.3 (MPa) | ||||

| Rotor speed ratio | 1:1.3 | ||||

| Rotor speed | 0-50 rpm/min, Frequency converter speed control | ||||

| Feeding method | Manual | ||||

| Rotor material | Carbide surface hard chrome mirror polishing | ||||

| Rotor hardness | HRC55-HRC60 | ||||

| Mixing chamber | The refining chamber adopts rotor structure: rotor by the long prongs, short prongs, rotor body and rotor through the inner cavity of the circulating cooling waterway composed of the main drive system power output speed using infinitely variable frequency speed control. | ||||

| Upper-pressure weight | Full pressure pneumatic, gas source pressure 0.5 ~ 0.8Mpa (customers provide their own gas source connection port) | ||||

| Control system | Purchase advanced RIGHT17.5 mixing software system, can be multi-stage control refining program selection | ||||

| Main motor【KW】 | 4.5 | 5.5 | |||

| Volume | About L1500*W900*H1850mm | About L1600*W980*H1850mm | |||

| Power supply | 3∮ 、AC380V 、22A three-phase, five-wire (PRC) | ||||

| Weight | About 450kg | About 550kg | About 680kg | About 780kg | |

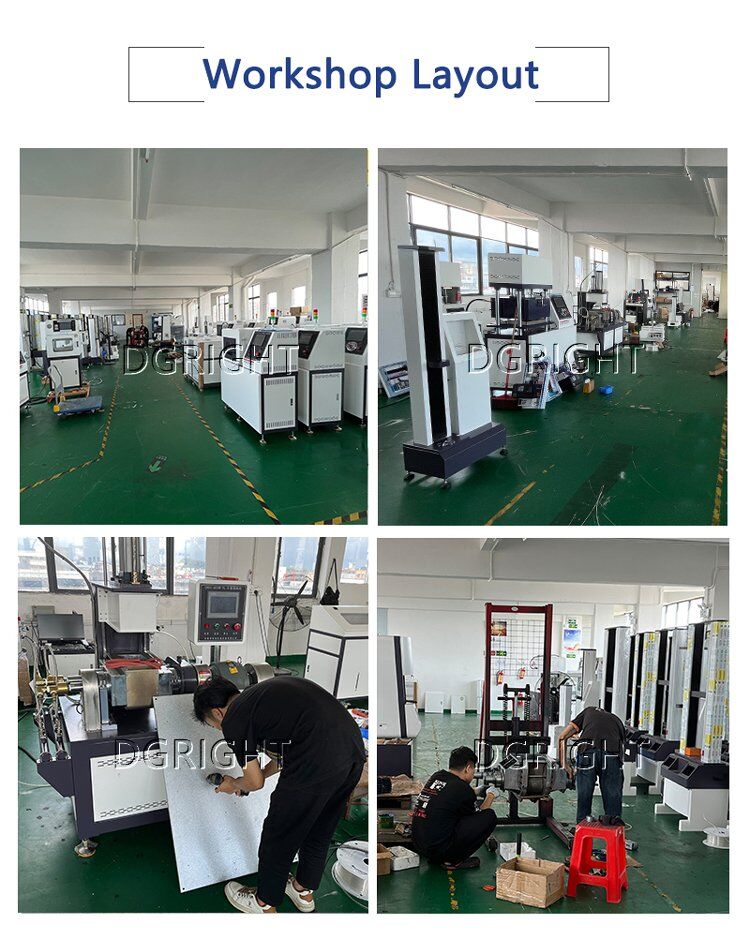

The Best Internal Rubber Mixer Manufacturer–DGRIGHT

Dongguan Right Instrument Co., Ltd. is a professional manufacturer dedicated to the research and development, design, manufacture and sales of rubber and plastic machinery and equipment. The company has a number of experienced engineers, deep plowing rubber and plastic testing machinery for many years, the introduction of Taiwan technology, production equipment and attentive after-sales service to provide customers with energy-saving products.

The company’s products mainly include rubber and plastic pressurized kneading machines, Open-type Rubber (plastic) Kneader Mixer Machines, EVA/TPR/PVC/masterbatch high-speed granulation production lines, rubber extruders, automatic rubber filters, calenders, rubber cutting machines, Internal Mixer production line, extruding and pressing machine, extrusion production line, calendering production line, etc. The products mainly serve the tire industry, sealing industry, and other industries, and they are widely used in the production of rubber products. The products mainly serve in tire industry, sealing industry, hose tape industry, cable industry, medical cork industry, as well as EVA, TPR, PVC, masterbatches, low smoke halogen free resistance cable material production, etc. The processed products are widely used in various fields such as rubber electronic parts, shoe materials, automobile parts, conductive rubber, industrial oil seals, oil rings, packaging, sports equipment, medical equipment and various utensils.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-109F Vacuum Vulcanizing Machine For Silicone Products Line

-

RT-108A Round Plate Rubber Rebound Resilience Elasticity Tester

-

RT-112 Rubber Hose Friction Tester

-

RT-108 Rubber Compression Rebound Tester

-

RT-107 Digital Rubber Akron Abrasion Machine

-

Rubber Low Temperature Brittleness Tester (RT-103)

-

RT-120B 10L Laboratory Banbury Rubber Internal Mixer

-

RT-110 Two Roll Open Mixing Mill (Electronic Heating & Water Cooling)

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)