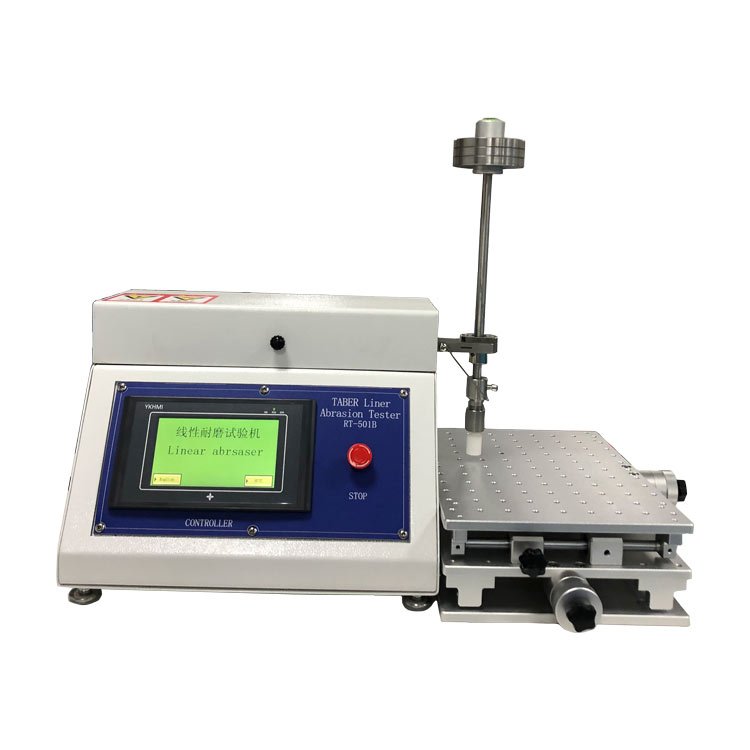

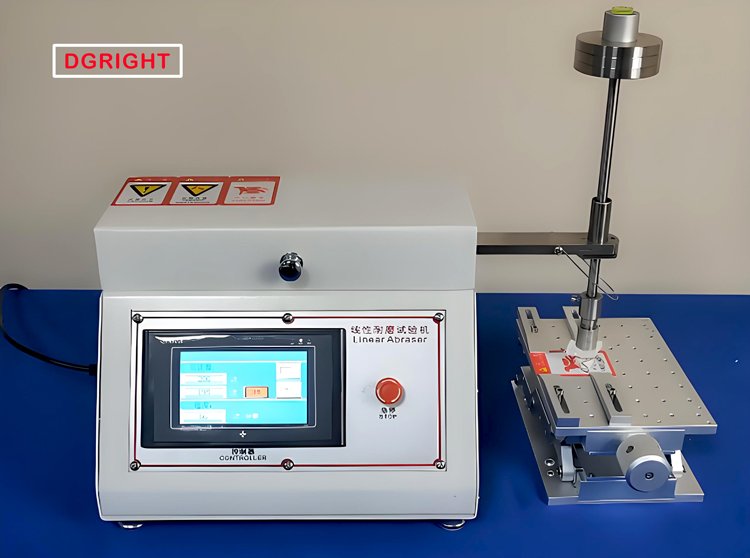

RT-501B TABER Liner Abrasion Tester

RT-501B Digital TABER Linear Abrasion Test Machine

Taber linear abrasion tester are used to evaluate the wear resistance, scratch resistance (single or multiple scratches) and color transfer properties (usually resistance to rubbing or rubbing fastness). Both dry and wet abrasion tests can be performed.

Product Details:

Application:

It can test samples of any size or shape, and is ideal for abrasion testing of products with contoured surfaces and polished surface properties (such as computer mouse and other computer or IT products, plastic topcoat abrasion resistance test), common to Plastics, auto parts, rubber, leather and textile, electroplating, freely disassemblable components, paints, printed patterns and more.

Standard Configuration:

1 mainframe, 1 35*35MM friction head, 1 rubber friction head, 3 500G weights, 1 box of CS-10 rubber strips (10 in a box)

Product Parameter:

| Volume | 430 x 280 x 480mm |

| Power connection | 220V 10A |

| The standard load range | 350G – 2100G |

| the maximum moving speed | 60 round/minute |

| Adjustable movement speed | 3.2~60 round/minute |

| The number of revolutions | 999,999 rpm |

| 5 optional moving distances | 0.5″, 1″, 2″, 3″ and 4″ |

Features:

1. Parameters such as moving distance, speed, revolution, and load can be set.

2. A wide range of different abrasion media and accessories can be selected. (Optional sample fixing table and other optional accessories, with the hang-on, breakage degree test, resistance to an alcohol test, resistance to coin scratching, etc.).

3. The eraser head at the end is made of high-quality abrasive material, which ensures the test’s stability.

4. RT-501B Linear Abrasion Tester complies with CE standards.

Ensure the stability of the test:

Generally, the size and shape of the grinding head are like the eraser head at the end of the pencil. It is made of the highest quality wear-resistant material to ensure the stability of the test.

Linear wear tester meets CE standards and has CE safety mark

Operating Instructions:

1. Insert the randomly distributed power cord into the power connection hole on the left side panel of the main unit and connect the power cord to a power source that complies with safety regulations.

2. Connect the power cord to the power supply in accordance with safety regulations. 2. Open the top cover of the main machine and adjust the left travel nut according to the testing needs. Insert the milling head coupling rod into the assembly hole at the right end of the main unit’s connecting rod (the milling head coupling rod weighs 350g). According to the test, we need to place the test sample and, adjust the required load, cover the host cover.

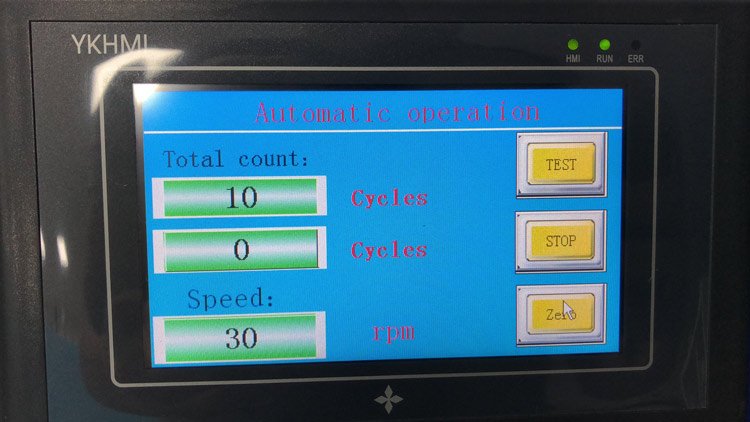

3. To enter the operation interface, turn on the main power switch on the left panel of the main unit.

4. Set the required speed and number of times for the test. (The larger speed is 60 laps per minute.)

5. Press the “start” switch to start running.

6. The number of times of running is automatically recorded during the operation, and it will stop automatically after reaching the preset value. If you need to re-test according to the last setting, directly click “clear”.

7. After the test is completed, turn off the main power switch on the left side of the host directly.

Maintenance matters:

1. The instrument needs to be placed on a stable ground before use.

2. It is not allowed to move the machine in the process of use.

3. Select the appropriate power supply voltage, do not overdo it, to avoid burning the device; 4. In the event of abnormalities in the instrument, please contact the Division in order to deal with it in a timely manner; 5.

5. Good ventilation is needed when the machine is working.

6. key mechanical components, due to the operation of the load, the mechanical part of the timely addition of lubricating oil; 7. each test is completed, clean up the machine, keep the machine clean; 8.

8. Control box part, must be wiped with a dry cloth, not with a wet cloth.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-517 Infrared Scanning Vertical Leather Measuring Machine

-

RT-516 Leather Thickness Meter, Leather Thickness Gauge

-

RT-512 Lab Color Matching Light Box for Color Matching

-

RT-511 IULTCS Leather Friction Color Fastness Tester

-

RT-510 Leather Low Temperature Flexing Testing Machine

-

RT-509B Digital Leather Lastometer Cracking Tester

-

RT-508 Electric Reciprocating Dyeing Rubbing Color Fastness Tester

-

RT-504 1800mm 2000mm Leather Tannery Width Leather Measuring Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)