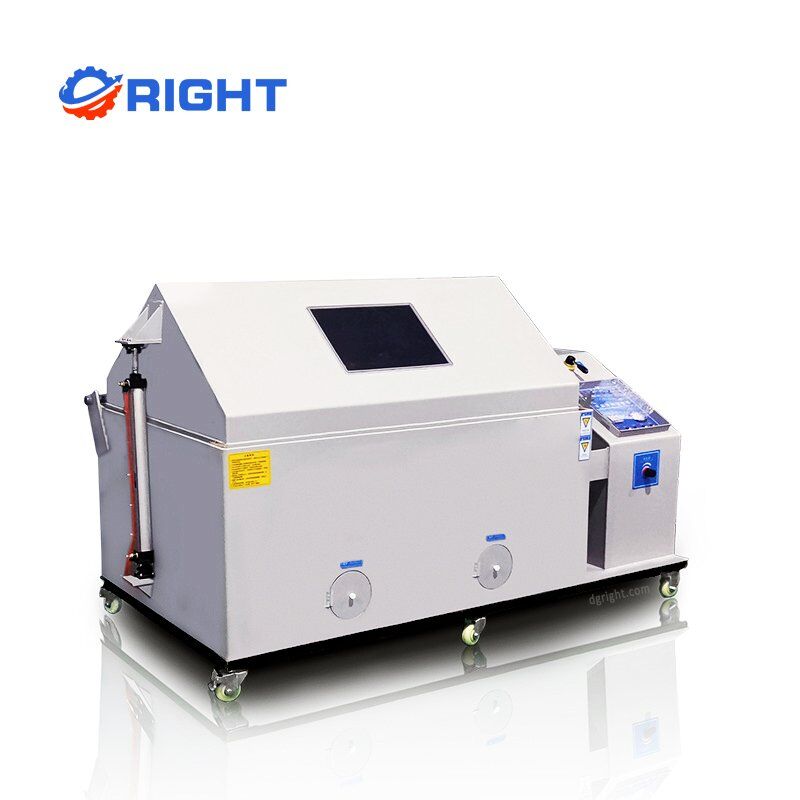

RT-311 Salt Spray Corrosion Testing Chamber

The Best Small Salt Spray Test Chamber (RT-311)

1. Spray method: A: continuous spray B: programmable spray.

2. Adopt a full detection system, which can be lighted when a fault occurs.

3. The whole set is made of imported PVC board. The structure is strong and never deformed, and it is resistant to acid, alkali, high temperature, and aging.

4. Adopt an automatic/manual water-add system. With this system, when the water level is insufficient, the test will not be interrupted, and the water level will be alarmed.

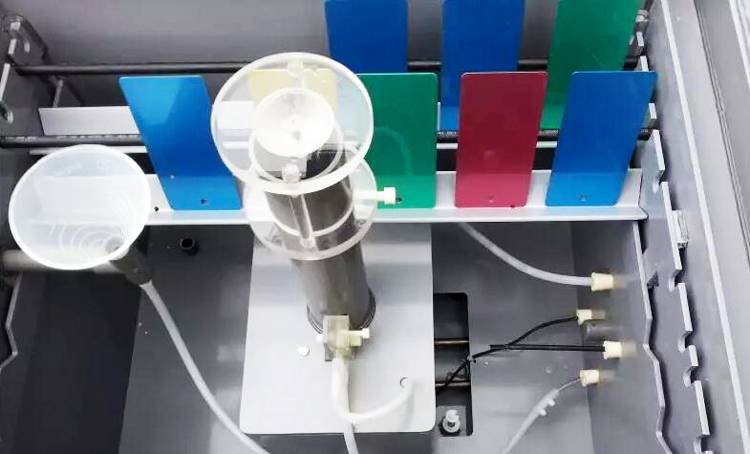

5. Quartz glass nozzle: the mist diffuses evenly and falls naturally on the test piece without blocking by crystalline salt.

6. The controllers are all on the same board, easy to operate, and clear at a glance.

7. With double over-temperature protection, warning of insufficient water level to ensure safe use.

8. The imported temperature controller has manual and fully automatic control methods. It uses a digital display and PID control, and the error ± 0.1 ℃. The maximum setting time can reach 999HrS.

9. The laboratory adopts the direct steam heating method; the heating speed is fast and uniform, and the standby time is shortened.

10. The spray tower is equipped with a conical diffuser, which guides the mist, adjusts the amount of mist, and evenly falls the mist.

11. The pressure barrel adopts Henry’s law to heat and humidify.

12. The upper cover of the test tank is automatically opened and closed by a pneumatic cylinder, which is easy to operate and has good safety.

13. After the test is completed, it has an automatic defogging device that allows one to clearly observe the test products in the test room.

Product Details:

Equipment Summary:

Salt spray testing chamber used to test the corrosive resistance of products whose surface was treated with paint, electroplating, inorganic and organic film, anode handling, anti-rust oil, etc.

Corresponding standard :

1.GB/T 2423.17-1993 salt spray test

2.ISO 9227 Corrosion tests in artificial atmospheres-Salt spray tests

3.GB/T 10125-1997 salt spray test

4.ASTM.B117-97 salt spray test

5.JIS H8502 salt spray test

6.IEC68-2-11 salt spray test

7.IEC68-2-52 1996 salt spray test

8.GB.10587-89 salt spray test

9.CNS.4158 salt spray test

10.CNS.4159 CASS Accelerated acetic acid copper salt spray test

11..GB/T 12967.3-91 CASS Accelerated acetic acid copper salt spray test

Technical Parameters:

| Model | RT-311A | RT-311B | RT-311C |

| Inside box size(cm) | 60x45x40 | 90x60x50 | 120x80x50 |

| Outside box size(cm) | 107x60x118 | 141x88x128 | 190x110x140 |

| Testing room temperature | Salt test (NSS ACSS)35℃±1℃/ Corrosion Test (CASS)50℃±1℃ | ||

| Pressure barrel temperature | Salt test (NSS ACSS)47℃±1℃/ Corrosion Test (CASS)63℃±1℃ | ||

| Brine temperature | 35℃±1℃ 50℃±1℃ | ||

| Testing room Capacity | 108L | 270L | 480L |

| Brine tank capacity | 15L | 25L | 40L |

| Salt concentration | The concentration of sodium chloride 5% or the 5% concentration of sodium chloride add 0.26g per liter of copper chloride (CuCl2 2H2O) | ||

| Air pressure | 1.00±0.01kgf/cm2 | ||

| Spray volume | 1.0~2.0ml/80cm2/h (working at least 16 hours, and then take the average) | ||

| Testing room relative humidity | 85% above | ||

| PH | 6.5~7.2 3.0~3.2 | ||

| Spray form | Programmable spray (Including continuous and intermittent spray) | ||

| Power | AC220V1Φ10A | AC220V1Φ15A | AC220V1Φ20A |

Essential Preparations Before Operating the Chamber

Before starting the test, specific preparations are necessary to ensure consistent and reliable test results:

1. Review Testing Standards

Familiarize yourself with international standards, such as ASTM B117, ISO 9227, and JIS Z 2371, to align your test procedures with global best practices.

2. Inspect the Equipment

Check the internal chamber, spray nozzles, salt solution tank, and air pressure system for any blockages, damage, or contamination.

3. Prepare the Test Samples

Clean the test samples thoroughly and mount them on the sample holders without overlap to ensure uniform exposure.

4. Solution Preparation

Accurate Preparation of a salt solution is key to obtaining reliable results. For a detailed method, refer to Step-by-Step Instructions for Preparing Salt Spray Chamber Solutions.

Operating the Salt Spray Chamber – Step-by-Step Process

Step 1: Power On and Set Parameters

Switch on the Salt Spray Chamber. Set the test duration, temperature (typically 35°C for neutral salt spray tests), air pressure, and fog collection rate according to standard requirements.

Step 2: Load the Salt Solution

Fill the tank with the prepared salt solution (usually 5% NaCl solution). Ensure the solution is free from impurities and properly filtered.

Step 3: Start Air Saturation

Activate the air saturator to heat and humidify the air before it enters the chamber. This ensures that the air is fully saturated for consistent fogging.

Step 4: Place the Test Samples

Carefully load the cleaned and mounted samples into the chamber. Ensure proper spacing for uniform exposure to the salt fog.

Step 5: Initiate the Test Cycle

Close the chamber lid securely and start the test. Monitor the fog density and temperature using the digital display on Pacorr’s Salt Spray Chamber.

Step 6: Test Monitoring and Mid-Test Checks

Although the test is automated chiefly, periodically check for:

Stable chamber temperature

Uninterrupted fog production

Nozzle blockages

Salt solution level

Step 7: Test Completion and Sample Removal

Once the cycle is complete, turn off the chamber. Open the lid carefully, wearing safety gear. Remove the test samples gently to avoid surface damage.

Post-Test Analysis and Reporting

After the test, the samples are evaluated visually or with measurement tools to assess:

Rust formation

Blistering

Peeling or cracking of coatings

Document all observations, along with photographs, and compare the results with specification standards.

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

Precision Neutral Acid Cyclic Corrosion Test Chamber (RT-327)

-

RT-716 High Temperature Muffle Oven for Ceramics

-

RT-318 Laboratory Battery Temperature Humidity and Vibration Test Machine

-

RT-317 Circulating Water Bath 6 Hole Constant Temperature Water Bath

-

RT-310 Thermal shock impact testing chamber

-

RT-308 ISO 20340 UV Simulate Environmental Solar UV Accelerated Aging Testing Chamber

-

RT-303 High and Low Temperature Testing Chamber

-

RT-301 Simulate Environmental Testing Chamber

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)