RT-310 Thermal shock impact testing chamber

RT-310 Thermal shock impact testing chamber

Thermal shock impact testing chamber(2 boxes) used to test the change of material under extremely high temperature and extremely low temperature environment that continue alternation in the shortest time, testing the chemical changes or physical damage of material caused by the thermal expansion and contraction.

Product Details:

Equipment summary:

Thermal shock impact testing chamber(2 boxes/3 boxes) used to test the change of material under extremely high temperature and extremely low temperature environment that continue alternation in the shortest time, Testing the chemical changes or physical damage of material caused by the thermal expansion and contraction. Testing box divided two parts, one is high-temperature region, another is low-temperature region, the testing sample placed on the moving basket, using unique heat storage and cool storage, the cylinder taking basket moves up and down in the hot and cold region to complete the hot and cold temperature impact testing; applied to test the material, including metal, plastic, rubber, electronics …. and other materials, it can be used as a basis for improvement of their products.

Main functions:

For electrical and electronic components, automation components, communication components, auto parts, metals, chemical materials and plastics industries, defense, aerospace, military industry, BGA, PCB base plate, electronic chip, IC, semiconductor ceramic and high-Changes in the physical sacrifice of molecular materials, test the material on the high and low tension and products arrived repeated thermal expansion and contraction of output in the chemical changes or physical injury, to confirm the quality of products, from the precision of the IC component to heavy machinery , And both need it the ideal test tool.

Control methods and characteristics :

It uses low temperature and high temperature thermal storage tanks to move the test product according to the test needs to achieve a rapid impact effect, balance the temperature control system (BTC), and control the SSPR by PID, so that the heating capacity of the system is equal to the heat loss, so it can Long-term stable use.

Corresponding standard:

- 1、GB/T2423.1-1989 low-temperature testing method

2、GB/T2423.2-1989 high-temperature testing method

3、GB/T2423.22-1989 change temperature test

4、5-86 temperature impact test

5、GJB360.7-87 temperature impact test

6、GJB367.2-87 405 temperature impact test - 7、 IEC60068 -3

Applicable industries:

Widely used in aviation, military, ships, electrical, electronics, instruments and meters; medical equipment; civilian nuclear energy; colleges and universities; research laboratories; commodity inspection, arbitration, technical supervision departments; building materials ceramic; petroleum and chemical products, machine and spare parts.

Technical parameters

| Performance (Air-cooled, refers to room temperature at +25℃, when no load) | ||

| 1.High temperature tank impact range | +60℃ ~ +150℃ | |

| 2.Low temperature tank impact range | -65℃ ~ -10℃ | |

| 3.High temperature tank temperature range | +60℃ ~ +200℃ | |

| 4.Low temperature tank temperature range | -65℃ ~ -10℃ | |

| 5.Shock recovery time | -65℃ ~ +150℃ about 5min no load(The sensor is placed at the air outlet of the unit) | |

| 6.Temperature uniformity | ±2.0℃ | |

| 7.Temperature fluctuation | ±0.5℃ | |

| 8.High and low temperature shock constant temperature time | Over 30min | |

| 9.Basket transfer time | ≦10S (Pneumatic automatic conversion) | |

| The temperature performance test is measured according to the relevant regulations of the IEC60068-3 standard; the sensor is placed at the air outlet of the unit | ||

| Structure | ||

| 1.Inner size | W 500 × H 300 × D 400 mm | |

| 2.External size | About W 1390 × H 2010 × D 2515 mm ) | |

| 3.Box structure | With independent product test area, high temperature heat storage area, low temperature storage area | |

| 4.Inner box material | Stainless steel plate (SUS 304#) | |

| 5.Outer box material | Steel plate baking paint | |

| 6.Insulation material | High temperature tank: 24k glass wool Low temperature tank: PU foam + glass wool | |

| 7Heater | Bare wire electric heater | |

| 8.Air circulation system | a. TECO Motor b. Stainless steel extended shaft c. Multi-wing fan (SIROCCO FAN) | |

| 9.Box door | Single door, 1 type each for high temperature and low temperature grooves a. Flat embedded handle b. Back button: SUS 304# c. Silicone foam tape | |

| 10.Test hole | One ψ50mm hole in the body and one silicone plug. | |

| 11.Sample rack | Stainless steel SUS 304# 2 storage trays. | |

| 12.Mobile casters | With movable casters (with foot cup). | |

| 13.transfer method | Cylinder drive。 | |

| 14.Tight | Silicone foam tight。 | |

| Refrigeration system | ||

| 1.compressor | German Bitzer semi-dense compressor or Copeland full-dense compressor | |

| 2.Refrigerant | Non-fluorine environmentally friendly refrigerant R404A R23, in compliance with environmental regulations, safe and non-toxic. | |

| 3.Condenser | Automatic cooling and high efficiency fin type with cooling motor (air cooling type). | |

| 4.Evaporator | High-performance fin type automatic load capacity adjustment, can be used for a long time under low temperature and high humidity conditions without frosting. | |

| 5.Other accessories | Expansion valve, oil separator, desiccant and other components are imported from internationally renowned brands. | |

| 6.Refrigerant flow control | The refrigeration system with automatic adjustment of energy consumption output control. | |

| 7.Refrigeration process | ※Full implementation of nitrogen shielded welding, two-stage rotary vane pump vacuum to ensure the internal refrigeration system Clean and reliable. ※The bottom of the compressor is designed with a drain pan, and the condensed water is drained out of the box through the drain pipe at the rear of the box. | |

| Controller | ||

| 1.Controller | Programmable AT-5188 true color LCD touch PLC architecture controller with multiple groups of intelligent PID control

| |

| 2.Screen display function | 7-inch resolution: 800*480, 65535 true color, LED backlight display screen Chinese/English language switch display, true color touch input Each box temperature setting (SV), actual (PV) value is directly displayed; Can display the execution program number, the current segment function, the remaining time and the number of cycles, and the running time display; Program editing and graphic curve display; Automatic prompt for defrost; When the program is executed, the graph curve can be displayed in real time, the segment can be skipped, and the function can be maintained; The fault is automatically prompted, and there is a corresponding solution prompt. | |

| 3.Control resolution | Temperature: + 0.1℃;time: 1min 。 | |

| 4.Setting Range | Upper limit of preheating temperature in high-temperature greenhouse: +220℃ Lower limit of preheating temperature in low temperature room: -80℃ Test room (sample area): high temperature +60℃ ~ +75℃; low temperature: -10℃ ~ -65℃ | |

| 5.Operation mode | High temperature →low temperature Low temperature → high temperature | |

| 6.Program capacity | Usable program capacity: maximum 127 groups; Time setting: 530 hours and 59 minutes per segment; Commands can be executed repeatedly: each command can reach 32,000 cycles. | |

| 7.Setting method | The man-machine dialogue mode adopts touch input and control. | |

| 8.Communication Interface | Can be connected to a computer to display curves and data collection; Can be used as a monitoring and remote control system; Can do synchronous control of multiple machines; RS-232, RS-485. | |

| 9.USB storage card | Can insert 1G-32G U disk to download historical curves, historical data, control system parameters, hot-swappable function. | |

| 10.Data recording method | With battery-protected RAM, it can save the set value, sampling value and sampling time of the device; the curve recording period can be set from 30 to 300 sec, and the maximum memory time can be stored continuously for 90 days of historical curves and historical data (when sampling The time is 1min), and the data is available for 10 years without continuous use. | |

| 11.Power-off memory function | The power-off recovery mode can be set as: hot start/cold start/stop. | |

| 12.Schedule boot function | The boot time can be set at will, and the machine will run automatically after the power is turned on. | |

| 13.Software use environment | Simplified Chinese/English Windows2000 or Simplified Chinese/English Windows XP operating system. | |

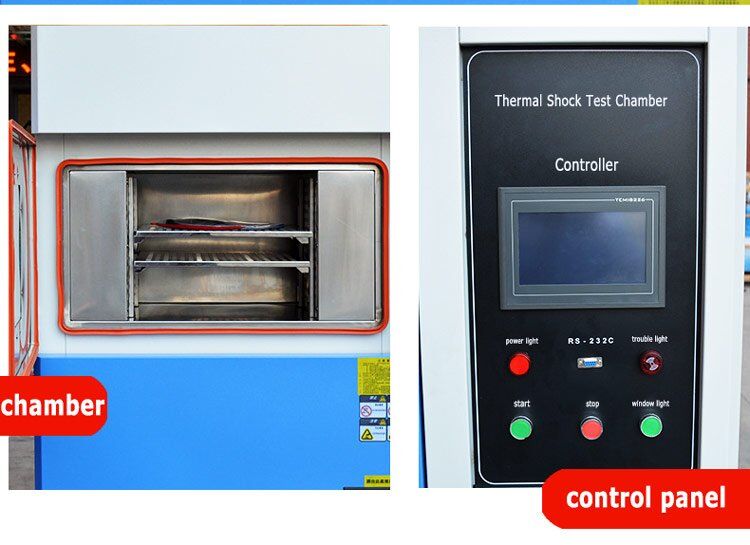

| Control Panel | ||

| a. Emergency stop switch b. Power switch c. Over-temperature protector d. RS-485 interface | ||

| Safety protection device | ||

| a. Heater air burning protection switch b. Heater overcurrent circuit breaker c. No fuse switch d. Circuit breaker e. Circulating fan over current overload protection f. Compressor high pressure protection switch g. Compressor overheating protection switch h. Compressor overcurrent protection switch i. Under-reverse phase protection switch | ||

| Installation and use conditions | ||

| 1.Using electric | AC 3ψ4W 380V 50HZ/ 220V 3ψ 60Hz(R.S.T.N phase plus ground wire)(Voltage fluctuation≦±10%)。 | |

| 2.Compressed air source | Please provide the compressed air source above 0.6MPa | |

| 3.Environmental temperature | Guaranteed operation ambient temperature range: 5~35℃. | |

| PS. 1. The above power requirements should be matched to the terminal block of the machine control box, and the customer should prepare a special non-fuse switch for this equipment; 2. The machine enters the door or passage elevator, etc., please confirm whether it can be entered; 3. This quotation does not include the cost of the power cord outside the machine. | ||

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

ASTM D5423 Air Ventilation Aging Climatic Test Chamber (RT-326)

-

Precision Neutral Acid Cyclic Corrosion Test Chamber (RT-327)

-

RT-308A Desktop UV Accelerated Aging Testing Chamber

-

RT-307A Xenon Lamp Aging Tester Manufacturer

-

RT-321 SO2 Gas Spray Sulfur Dioxide Test Chamber

-

RT-318 Laboratory Battery Temperature Humidity and Vibration Test Machine

-

RT-317 Circulating Water Bath 6 Hole Constant Temperature Water Bath

-

RT-304A Walk-in Constant Temperature and Humidity Test Chamber

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (3)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (24)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (41)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)