RT-118 Rubber Trimming Machine

RT-118 Rubber Trimming Machine

Rubber Automatic split edge machine using centrifugal principle , the inner cylinder with automatic control

of high-speed rotating disk driven rotating rubber products constantly collide , making edges and rubber

products separated from each other , so as to achieve the function of removing burrs.

Product Details:

Product Description

Rubber Automatic split edge machine using centrifugal principle , the inner cylinder with automatic control

of high-speed rotating disk driven rotating rubber products constantly collide , making edges and rubber

products separated from each other , so as to achieve the function of removing burrs . Set of high-

performance , high- yield, high- benefit one, perfect to replace the manual , such as freezing and punching

processes traditionally used to enhance the corporate image and competitiveness. Applies to all rubber

seals and other rubber parts molding burrs after the demolition work, demolition can be directly molded

rubber side throughout . Detachable side or wall thickness as shaped pieces of rubber O-rings , Y -rings ,

gaskets, stoppers , rubber, solid burr in 2MM thickness or more and less than 0.1-0.2MM, metal-free ,

there are knife-edge tear side ( also known as cut mouth ) of various rubber products.

Product Features:

♦ High production efficiency , the amount of an automatic split -machine equivalent of a hook flash

processed daily workload 10-15 skilled workers (the product is smaller, the greater the capacity ,

especially for 5mm-80 mm in outside diameter of the product ) . The machine can automatically

control the speed and timing of the demolition side , so that the whole process realizes intelligent,

productivity is manually operated For 40-50 times , each machine / peeling rubber ring 80000pcs

per hour or so, more than 99% separation after processing products no deformation, no damage.

♦ Automatic demolition machine to the side edge and stable quality , precision and demolition side

pass rates significantly higher than the manual work ( traditional manual operations slow hook flash ,

flash and more, scratches, hookBroken , mixed goods, dirt and other serious ) .

♦ similar equipment in the most cost ; low cost , power consumption of less than 3 degrees per hour ,

without the use of liquid nitrogen , and the price is much lower than freezing equipment trimmer or import

Equipment. Processing any rubber products, do not die and more efficient than stamping deburring way .

♦ The built- cleaner , the product is automatically pumped discharge flash separation , saving burrs

and product separation time .

♦ The machine is divided vote silos and work positions , seamless access to materials , etc. without

having to reboot every time down the action , just to feed continuous flow process .The whole process

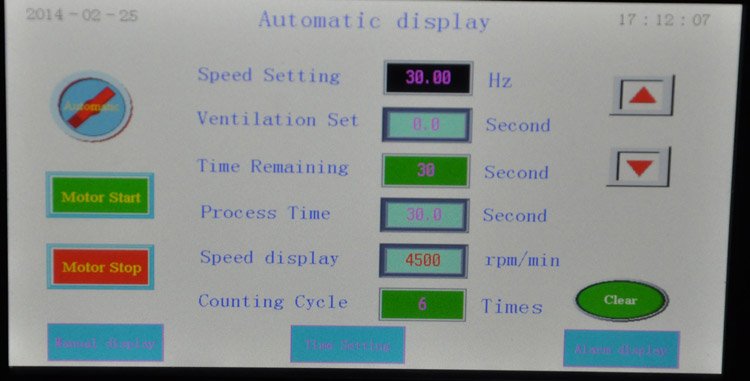

is usedPLC control, touch screen interface to adjust the parameters , more intuitive and convenient

operation more accurate. After half an hour of ordinary workers trained to operate properly.

♦ safety, machine operation the front left and right sides of the installation of an emergency stop

button for easy emergency shutdown .

Technical parameters:

| Processing Modulus | 8-15 modulus(Weighted ≤2KG |

| Mold dimension | 320*320-460*460 |

| Trim Efficiency | 20S-65S/per time |

| Settled Rational Speed | 3000-6000 turn/per minute |

| Manufacture Dimensions | O Sealing Ring, Y ring and washer, outer d≤80MM,1.5MM≤wire d≤5.0mm |

| Noise | ≤78dB |

| Working Power | four wire three phase AC 380V 50HZ |

| Power | 3 KW |

| Dimensions | 1800 × 550 × 1000 MM |

| Weight : | 350 KG |

Start Earning Substantial Profits In Your Country Today!

RIGHT has helped customers in more than 100 countries to be successful and earn good profits. We also welcome you to become an exclusive distributor in your country.

After signing the agreement, we will not wholesale any more products to your country or region, your orders will be processed and shipped first, and we will execute your custom machine design after you send us the first time. Click the buttons below, and let’s grow your brand together.

RIGHT's Services Always Go Extra Mile

No more endlessly wasting time on other lousy suppliers. RIGHT's goal is to let you sit back and relax. We take care of all the dirty works, including trade stuff, clearance and logistics, etc. Our consultant will keep you informed of the trade progress throughout.

Related products

-

RT-108A Round Plate Rubber Rebound Resilience Elasticity Tester

-

Plastic Hot Press Forming and Rubber Vulcanizing Press Machine Manufacturers

-

RT-117A Pointer Type Thickness Gauge

-

RT-113A Vulcanized Rubber Distortion of Permanent Compression Testing Machine

-

RT-107 Digital Rubber Akron Abrasion Machine

-

Demattia Flexing Fatigue Tester (RT-105)

-

Rubber Moving Die Rheometer MDR Rotorless Curemeter Price (RT-101)

-

RT-109A Lab Rubber Vulcanizing Press Machine

Product Categories

- 1. Rubber Testing Machine (36)

- 10. Abrasion testing machine (5)

- 11. Cable/ Wire Testing Machine (9)

- 12. PPE Testing Equipment (17)

- 13. Enameled Wire Testing Machine (9)

- 14. Video Measuring Machine (3)

- 15. Precision Colorimeter (1)

- 16. Hardness Testing Machine (4)

- 17. Metal Detector (2)

- 18. Moisture Meter (3)

- 19. Tape Testing Machine (3)

- 2. Plastic Testing Machine (72)

- 20. Furniture Testing Machine (1)

- 21. Whiteness Meter (1)

- 22. Battery Test Equipment (1)

- 23. Mobile Electronic Product Tester (1)

- 3. Tensile Testing Machine (23)

- 31. Lubrication System Test (1)

- 4. Compression Testing Machine (10)

- 5. Paper and Carton Box Testing Machine (40)

- 6. Textile Testing Machine (64)

- 7. Simulated Environment Testing Machine (26)

- 8. Leather Testing Machine (23)

- 9. Shoes Testing Machine (11)